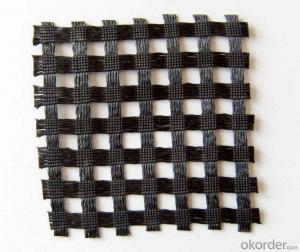

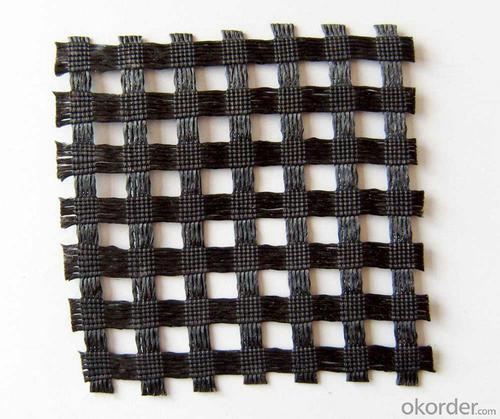

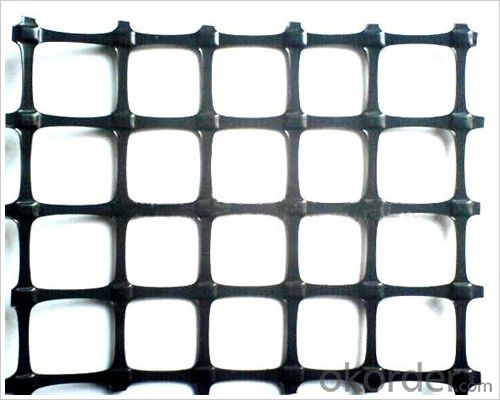

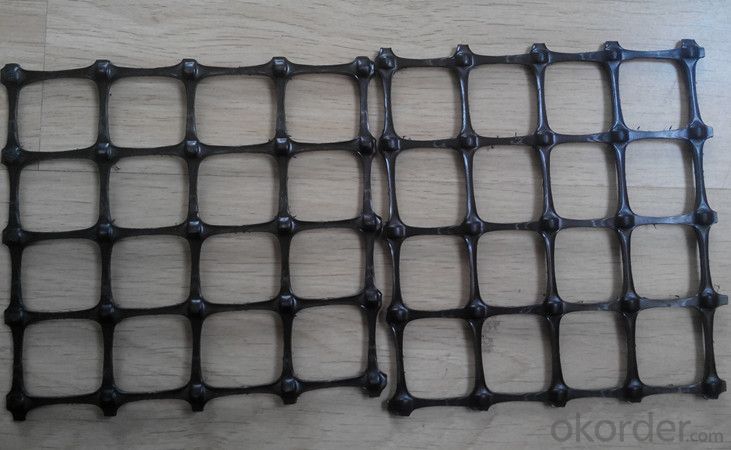

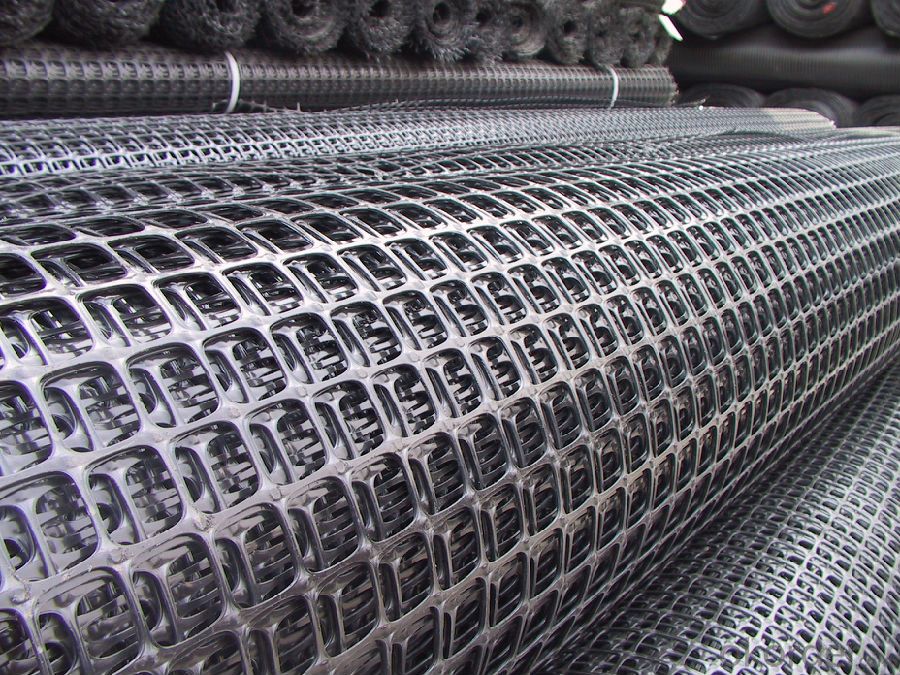

Geogrids for Tree Protection - BX Tensile Strength Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: PVC HF what is the material PVCHF bidirectional geogrid is like?

- General synthetic resin. Depending on the addition of plasticizers, can be divided into two types of hard and soft pvc.

- Q: What is a one-way plastic geogrid

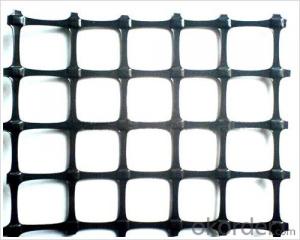

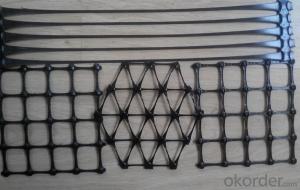

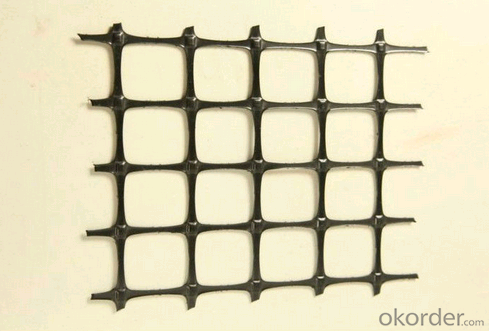

- The plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: Is there a geogrid in the transition section of Railway

- The general design is a one-way or two-way Plastic Geogrid

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, project requirements, and installation method. It is essential to consult with geotechnical engineers or geosynthetic specialists who can analyze the specific project needs and recommend the most suitable geogrid aperture shape, which can range from square to rectangular or triangular.

- Q: What is the typical geogrid roll thickness for specific applications?

- The typical geogrid roll thickness for specific applications can vary depending on the specific project requirements and site conditions. However, geogrid rolls typically range from 2 to 10 millimeters in thickness for common applications such as soil stabilization, retaining walls, and road construction.

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids are engineered materials that provide stability and reinforcement to slopes by distributing and transferring loads. They effectively improve soil strength and prevent erosion, making them an ideal solution for reinforcing steep slopes and enhancing their stability.

- Q: Can geogrids be used in temporary construction platforms?

- Yes, geogrids can be used in temporary construction platforms. Geogrids are commonly used in construction projects to reinforce soil and provide stability. They can be used as a cost-effective solution for temporary construction platforms by improving load-bearing capacity and preventing soil erosion.

- Q: What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on several factors such as the type of geogrid, soil conditions, and project requirements. Some common geogrid connection methods include using mechanical connectors, overlapping and sewing the geogrid panels, or using adhesive bonding. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the most suitable connection method for a specific application.

- Q: High density polyethylene one-way geogrid, tensile yield of 20kn/m

- Material is high density polyethylene material

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement and stabilization to the soil. They are typically made of high-strength materials, such as polyester or polypropylene, and are placed within the soil layers to distribute loads and increase its bearing capacity. This allows for the use of thinner soil layers, reducing the amount of excavation required. Additionally, geogrids prevent soil erosion and improve soil stability, minimizing the need for costly replacements of poor soils.

Send your message to us

Geogrids for Tree Protection - BX Tensile Strength Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords