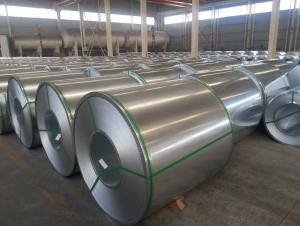

Gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection. |

| Delivery Detail: | 3-10days after receving the deposite |

Specifications

gavanized steel coil

1) cold rolled steel plate

2) SUCC ,DC01 ,SPCC.

3) Standard GB13237 Q/ ASB 334

- Q: What are the common coil tests performed for quality control?

- Some common coil tests performed for quality control include tension tests, bend tests, hardness tests, and dimensional checks. These tests help to ensure that the coils meet the required specifications and are of high quality.

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- What Is Cold Steel

- Q: I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- If you decide to get a true pedal steel, plan on spending some big money. Look on eBay for a Carter Starter. It will be the best guitar to start on...and not outgrow too fast.

- Q: What are the environmental considerations of using steel coils?

- There are several environmental considerations associated with using steel coils. Firstly, the production of steel coils requires a significant amount of energy and raw materials, which can contribute to greenhouse gas emissions and environmental degradation. Additionally, the extraction and processing of iron ore for steel production can have negative impacts on land, water, and air quality. Moreover, the transportation of steel coils, especially over long distances, can result in emissions from vehicles and contribute to pollution. Lastly, the disposal of steel coils at the end of their lifecycle poses challenges as they can be difficult to recycle and may end up in landfills, further contributing to waste accumulation. Overall, the environmental implications of using steel coils highlight the need for sustainable practices in their production, transportation, and disposal.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and repurposed for various applications in different industries.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment as they provide the necessary strength and durability required for components such as chassis, frames, and body panels. These coils are shaped, cut, and welded to create different parts, ensuring the structural integrity and safety of vehicles such as cars, trucks, and trains.

- Q: How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being formed into a helical shape, allowing them to store and release energy when subjected to force or pressure.

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- *Alloy steel is not same as stainless steel. An alloy steel is not the perfect spring steel. Since you are doing the project, please understand the carbon steel,alloy steel and super alloys. Alloy steel is steel alloyed with a variety of elements in amounts of between 1 and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. Stainless steel is a type of high alloy steel. *As far as spring material is concern , spring steel or music wire is best suited. Spring steel is a low alloy, medium carbon steel or high carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant bending or twisting. Silicon is the key component to most spring steel alloys. An example of a spring steel used for cars would be AISI 9255 (DIN and UNI: 55Si7, AFNOR 55S7), containing 1.50%-1.80% silicon, 0.70%-1.00% manganese and 0.52%-0.60% carbon. Most spring steels (as used in cars) are hardened and tempered to about 45 Rockwell C. Since sufficient links were given earlier but I like you to go through spring steel as it is your subject matter. I have done the project on The design of a helical compression spring selected material was ASTM A228 (0.80–0.95% carbon).

- Q: What are the common transportation defects in steel coils?

- Steel coils can experience various transportation defects. Improper handling or securing during transportation is a major cause of coil damage, resulting in dents, scratches, or tears in the steel. Coil edge damage is another issue that arises when the coils lack proper protection or rub against each other during transit, leading to deformation or breakage of the edges. Additionally, coil shifting occurs when the coils are inadequately secured or braced, causing them to move and shift during transportation, potentially causing misalignment or damage. Moreover, coil corrosion is a prevalent defect that arises when the coils are exposed to moisture or corrosive elements during transportation, leading to rust and deterioration of the steel. To prevent these common transportation defects in steel coils, it is essential to implement appropriate handling, securing, and protection measures.

- Q: How are steel coils used in the manufacturing of construction materials?

- Steel coils are used in the manufacturing of construction materials as they are rolled into various shapes and sizes to create structural components like beams, columns, and studs. These coils are also used to produce roofing and siding materials, reinforcing bars, and wire mesh, providing strength and durability to different construction applications.

Send your message to us

Gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords