Galvanized SteelCoil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

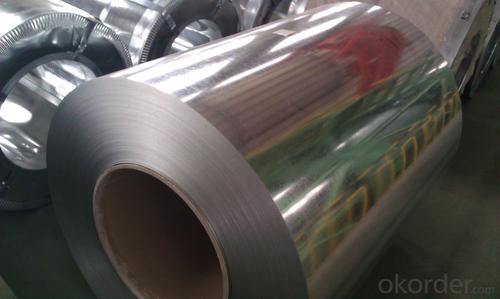

Galvanized Steel Coil gets coated in layers of zinc because rust won't attack this protective metal. The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel. For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

HOT DIP GALVANIZED STEEL COIL

STEEL GRADE & STANDARD:JIS G3302 SGCC

ZINC COATING MASS:Z12

SPANGLE:REGULAR SPANGLE

SURFACE TREATMENT:CHROMATED,UNOILED,NONSKINPASSED

THICKNESS:1.20MM

WIDTH:1200MM

COIL ID:508MM

COIL WEIGHT:4-7MT

WIDTH TOLERANCE:0/+5MM

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: Can solution annealing be done on carbon and low alloy steels. please give an explanatory answer.

- No. Carbon steel has two different crystal structures, FCC and BCC , depending on the temperature. when you heat steel up and then quench it, it locks the crystal structure into the BCC form. this makes it hard. whereas precipitation hardened austentic stainlesses remain BCC regardless of the temp, so the hardness change is not a function of thermally induced strain. you can anneal carbon steel but the thermal profile is closer to the precipitation profile of PH stainlesses than it is to the Solution annealing profile.

- Q: What are the dimensions of steel coils used in the agricultural machinery industry?

- The dimensions of steel coils used in the agricultural machinery industry can vary depending on the specific application and machinery. However, common dimensions for steel coils in this industry range from 0.4 to 2.5 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can vary based on the requirements of the machinery and production process.

- Q: What are the different coil handling equipment options available for steel coils?

- There are several different coil handling equipment options available for steel coils, depending on the specific needs and requirements of the industry. 1. Coil Cars: Coil cars are used to transport steel coils from one location to another within a facility. They are typically equipped with hydraulic or mechanical lifting mechanisms to safely load and unload the coils onto other equipment or storage racks. 2. Coil Upenders: Coil upenders are used to rotate steel coils from a horizontal to a vertical position, or vice versa. This equipment is essential for loading and unloading coils onto coil cars or other machinery, as well as for storage purposes. Upenders can be operated manually or hydraulically, depending on the weight and size of the coils. 3. Coil Lifters: Coil lifters are designed to safely handle steel coils during lifting and transportation. They are typically equipped with adjustable arms or hooks that securely grip the coil's inner diameter. Coil lifters can be operated using hydraulic, mechanical, or electromagnetic mechanisms, depending on the weight and size of the coils. 4. Coil Turnstiles: Coil turnstiles are used to efficiently store and retrieve steel coils. They are designed to hold multiple coils in a vertical position, allowing for easy access and retrieval. Turnstiles can be rotated manually or automatically, using hydraulic or mechanical systems. 5. Coil Reels: Coil reels are used to unwind steel coils and feed them into processing machinery, such as stamping presses or roll forming machines. They are equipped with adjustable tension controls to ensure a smooth and consistent feed. Coil reels can be operated manually or automatically, depending on the level of automation required. 6. Coil Cradles: Coil cradles are used to support steel coils during storage or transportation. They are designed to evenly distribute the weight of the coil, preventing deformation or damage. Coil cradles can be stationary or equipped with wheels for easy movement. Overall, the different coil handling equipment options available for steel coils provide a range of solutions for efficient and safe handling, storage, and processing of these heavy and valuable materials. The choice of equipment will depend on factors such as coil size, weight, production volume, and specific industry requirements.

- Q: which is the most tough and durable steel type ??

- C'mon. Really? That's your question? How about some actual details like the application, is it going to be formed into a shape, do you need to weld it, what type of environment like corrosion and temperature is it going to be subject to? There are roughly 2,000 grades of steel and a couple hundred grades of stainless steel. Steels can be soft or they can be exceptionally hard. We need more info please.

- Q: How are steel coils tested for tensile strength?

- Steel coils are tested for tensile strength through a process called tensile testing. In this method, a small sample is taken from the steel coil and subjected to a controlled force until it breaks. The force applied during the test is gradually increased until the sample fractures. The maximum force required to break the sample is measured, and this provides valuable information about the tensile strength of the steel coil.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are commonly used in the manufacturing of machinery as they provide a versatile and reliable raw material. These coils are processed and shaped into various components, such as gears, shafts, and frames, that are essential for the functioning of machinery. The strength and durability of steel make it an ideal choice for withstanding heavy loads and high temperatures, ensuring the longevity and efficiency of machinery in different industries.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components as they serve as the primary raw material for producing various parts such as car bodies, chassis, and engine components. The coils are processed through a series of manufacturing techniques, including cutting, shaping, and welding, to transform them into specific automotive components. The high strength and durability of steel make it an ideal choice for these applications, ensuring the structural integrity and safety of the final automotive products.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being formed into cylindrical shapes and then machined to create the desired dimensions and features of the shaft. The steel coil is typically cut to the required length and then undergoes a series of manufacturing processes, such as forging, heat treatment, and machining, to produce a strong and durable transmission shaft.

- Q: How are steel coils used in the production of structural components?

- Steel coils are used in the production of structural components as they serve as the primary raw material for various manufacturing processes. These coils are typically processed through rolling mills, where they are heated, shaped, and transformed into different structural shapes, such as beams, columns, and plates. The high strength and durability of steel make it an ideal choice for constructing buildings, bridges, and other infrastructure, ensuring the structural integrity and longevity of these components.

Send your message to us

Galvanized SteelCoil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords