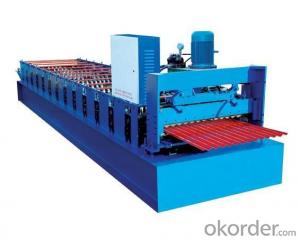

GALVANIZED STEEL ROOF ROLL FORMING MACHINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

35-205-820 type of glazed tile machine including molding host, hydraulic station, feeding, molding cut, control box, discharge frame. Caigang glazed tile equipment roller die forming of archaize glazed tile with good appearance, of primitive simplicity and elegant, elegant chic modelling, such characteristics as high grade, can be widely used in factories, tourist scenic spot, pavilions, garden hotel, exhibition hall, resort villa, family and other buildings and outdoor decoration. Glazed tile press production line with galvanized steel plate color or different color steel or aluminum as raw materials, production of products used in the roof of the building external plate and wall board and interior decorating plate or, ceiling, etc., increase the roofs or walls of aesthetics, and durability.

| model | 35-205-820 | usage |

| effective width(mm) | 820 | |

| coil width(m) | 1-1.25 | wall/roof plate |

| coil thickness(mm) | 0.5-1.5 | |

| groove distance(mm) | 205 |

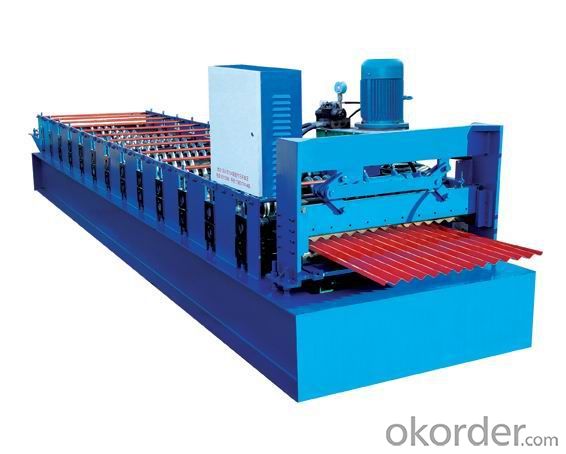

Corrugated panel roll forming machine

Main Teachnical Parameters

1.Material thickness: 0.2-1.0mm

2.Feeding width: 900mm

3.Effective width: 760mm

4.Forming speed: 12-16m/min

5.Diameter of the shaft: 70mm

6.Main power: 4KW

7.Forming steps: 16 steps

8.Material of shaft: 45#steel, quenched and tempered

9.Side board thickness: S18mm

10.Material of Rollers: Bearing steel

11.Driven style: by chain

12.Control system: Panasonic PLC

13.Hydraulic cutting part

i.Power: 3 KW

Material of cutter: Cr12, quenched

- Q: What are the shortcomings of traditional machining?

- First, the production efficiency is low, the cost, followed by the processing quality is not stable, the third labor intensity, lack of security.

- Q: Information on building materials decoration.

- Products Special Building Materials Ceiling Coatings Culture Stone Bamboo Processing Machinery Brick, Watt and Block Decorative Building Materials Agent

- Q: Information on building materials decoration.

- What are the building materials industry? Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moistureproof Materials Heat Absorbing Sound Absorbing Materials Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related Equipment Construction Project Cooperation Adhesive Metal Building

- Q: Classification and components of hydraulic press

- According to the control mode classification According to the control mode, the hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- To do the theoretical basis of mechanical design is essential, learn a few auxiliary tools, CAD, PRO / E, slidworks are more commonly used.

- Q: Main classification of hydraulic machinery?

- (2) according to the size of the equipment according to the size of equipment, hydraulic equipment can be divided into large equipment, medium-sized equipment, small equipment.

- Q: What gear is machined out of the gear?

- Early in the universal milling machine, with the indexing head index, with the shape of the cutting edge and gear groove shape of the same forming disc cutter or milling cutter milling manufacturing.

- Q: What is the principle of the cutting order in machining?

- ③ the first main after the first processing of the main surface, and then processing the secondary surface.

- Q: What are the aspects of the mechanical processing quality

- Parts of the processing accuracy includes three aspects of the content; dimensional accuracy, shape accuracy and position accuracy

- Q: What are the oyster processing companies?

- Processing industry is divided into two categories: 1 finished product processing: building materials processing drugs processing sports products processing environmental protection equipment processing energy products processing shoe materials, shoe processing medical equipment processing audio and video products processing instrumentation processing industry special equipment processing hardware tools processing jewelry processing apparel Processing of finished shoes processing spray processing stone processing bamboo processing paper processing electronic processing including | patch processing plug-in processing bonding processing electronic assembly processing welding proc

Send your message to us

GALVANIZED STEEL ROOF ROLL FORMING MACHINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords