Galvanized Steel Coil Factory Hot Dipped/Cold Rolled JIS ASTM DX51D SGCC

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 T

- Supply Capability:

- 5000 T/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,ASTM

Technique:

Cold Rolled,Hot Rolled,ERW

Shape:

Round

Surface Treatment:

Galvanized

Steel Grade:

Q195

Certification:

SGS,SNI,ISO

Thickness:

0.12-0.2mm

Width:

600 - 1250MM

Length:

As Requirments

Net Weight:

3-5 Tons

Packaging:

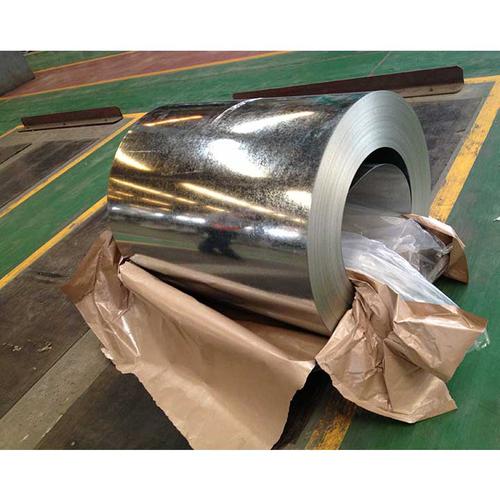

Dust-proof kraft sheet、 Iron packing、 Angle protective 、Packing belt、Wood pallet

Application:

cutting sheets, making corrugated sheets

Coating:

Z121-Z180

Brand Name:

sino steel

Hardness:

Full Hard

Delivery Time:

31-45 days

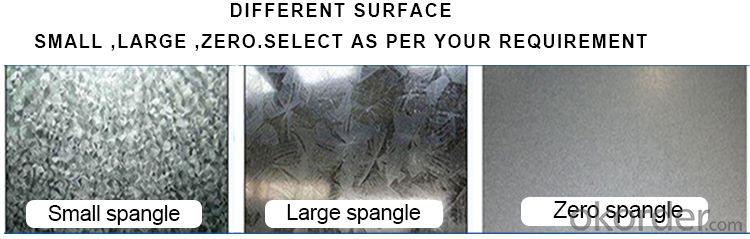

Spangle Type:

Regular spangle,Minimum spangle, Zero spangle, Big spangle

| Galvanized Coil/Sheet | |

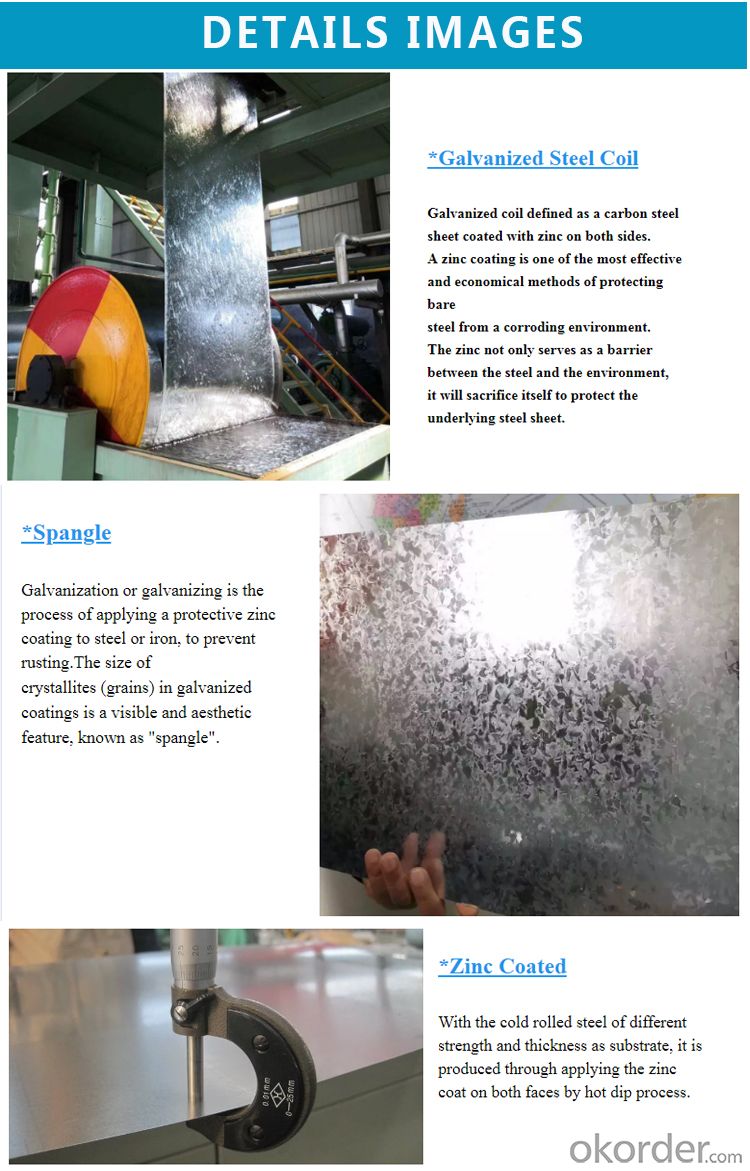

| The thin steel plate is immersed in the dissolved zinc bath so that its surface adheres to a thin steel plate. It is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the plating groove dissolved with zinc to make galvanized steel plate. This steel plate is also made by hot immersion, but after the groove, it is immediately heated to about 500 ℃, so that it generates an alloy film of zinc and iron. This galvanized coil has good coating adhesion and weld ability. Galvanized coil can be divided into hot rolled galvanized coil and cold rolled galvanized coil, they are mainly used in the construction of household appliances, car containers, transportation and other fields, especially steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries their characteristics are mainly: strong corrosion resistance, good surface quality, economic and practical. | |

| Thickness | 0.105- 4MM |

| Width | 600 - 1250MM |

| Length | As require |

| Zinc Coating | Z30 - 600g//m2 |

| ID of Coil | 508/610MM |

| Surface Structure | Regular spangle,Minimum spangle, Zero spangle, Big spangle |

| HRB | Soft Hard (<60),Medium Hard (60-85), Full Hard (85-95) |

| Surface Treatment | Oiled (O), Chromium (C),Phosphating (P), Spinpass |

| Standard Seaworthy Export Packing | Dust-proof kraft sheet, iron packing, Angle protective, packing belt |

| Coil Weight | 3-5 Tons |

| Standard | ASTM-A653; JIS G3302; EN10147;etc |

| Payment Terms | T/T, LC, Western Union, Paypal, O/A, DP |

| Regular Order | 25 tons or one container, for less quantity, to contact with us for details. |

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- Sorry troll, doctors don't give a tetanus shot just because you came into contact with rusty metal. The belief that you need a tetanus shot for stepping on a rusty nail is not quite accurate -- it's not the rust that prompts the shot, it's the fact that the nail was on the ground and dirty.

- Q: What are the different types of packaging for steel coils?

- There are several different types of packaging options available for steel coils, depending on the specific requirements and preferences of the manufacturer or distributor. Some of the most common types of packaging for steel coils include: 1. Wooden Crates: Steel coils can be packed in wooden crates, which provide excellent protection against damage during transportation and handling. These crates are typically made of strong and durable wooden materials, such as plywood or solid wood, and are designed to securely hold the steel coils in place. 2. Steel Frames: Another common packaging option for steel coils is steel frames. These frames are constructed using sturdy steel materials and are designed to hold the coils securely in place to prevent any movement or shifting. Steel frames are often used for larger or heavier coils, as they offer enhanced stability and durability. 3. Cardboard Boxes: For smaller or lighter steel coils, cardboard boxes can be a suitable packaging option. These boxes are typically made of strong and durable cardboard materials, and they provide adequate protection against minor impacts and scratches. Cardboard boxes are also easy to handle and can be conveniently stacked or stored. 4. Plastic Wrapping: In addition to using crates, frames, or boxes, steel coils can also be wrapped in plastic materials for added protection. Plastic wrapping is typically used to secure the coils and protect them from moisture, dust, and other external elements during transportation and storage. This type of packaging is commonly used in conjunction with other packaging options. 5. Transportation Racks: For efficient handling and transportation, steel coils can be packaged in specially designed transportation racks. These racks are typically made of steel or other strong materials and are designed to securely hold the coils in place. Transportation racks allow for easy loading and unloading of the coils and provide enhanced safety during transit. Overall, the type of packaging chosen for steel coils depends on factors such as the size and weight of the coils, the transportation method used, and the level of protection required. Manufacturers and distributors often consider these factors in order to select the most appropriate packaging solution that ensures the safe and efficient handling of steel coils throughout the supply chain.

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: What is the average shelf life of a painted steel coil?

- The average shelf life of a painted steel coil can vary depending on several factors such as the type of paint used, the storage conditions, and the level of exposure to environmental elements. However, on average, a painted steel coil can have a shelf life ranging from 5 to 20 years.

- Q: At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q: How do steel coils withstand extreme temperatures?

- Steel coils are able to withstand extreme temperatures due to their unique composition and manufacturing process. Steel, the primary material used in coils, is an alloy of iron and carbon that possesses excellent thermal properties. Its high melting point, which can reach up to 2,500 degrees Fahrenheit (1,370 degrees Celsius), allows it to remain structurally stable under intense heat. Furthermore, steel coils are often subjected to a process called annealing, which involves heating the steel to a specific temperature and then slowly cooling it down. This annealing process helps relieve internal stresses within the steel, making it more resistant to thermal expansion and contraction. By reducing the presence of internal defects, annealing also enhances the steel's overall strength and durability, allowing it to better withstand extreme temperatures. Moreover, steel coils are often coated with protective layers to provide additional resistance against temperature variations. These coatings, such as galvanized or zinc coatings, act as a barrier between the steel and the external environment. They help prevent oxidation, corrosion, and other forms of degradation that can occur when exposed to extreme heat or cold. In summary, steel coils are able to withstand extreme temperatures due to the inherent properties of steel, the annealing process that relieves internal stresses, and the protective coatings that provide an extra layer of resistance. These factors work together to ensure that steel coils remain structurally stable and maintain their performance even in the harshest temperature conditions.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality of the raw material used, the thickness and width of the coil, the temperature and humidity during the manufacturing process, the tension applied during coiling, and the cooling and leveling processes employed.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: and what type of metal is steel?

- From the steel store. ;) Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.14% by weight (C:110–10Fe), depending on grade. Carbon is the most cost-effective alloying material for iron, but various other alloying elements are used such as manganese, chromium, vanadium, and tungsten.

- Q: Can steel coils be stored in a humid environment?

- Steel coils should not be stored in a humid environment as high humidity can lead to corrosion and rust formation on the steel surface, compromising its quality and durability. It is important to store steel coils in a dry and well-ventilated area to maintain their integrity and prevent any potential damage.

Send your message to us

Galvanized Steel Coil Factory Hot Dipped/Cold Rolled JIS ASTM DX51D SGCC

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 T

- Supply Capability:

- 5000 T/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords