Galvanized Aluminum Sheets - Aluminum Household Foil AA8011 0.009-0.030mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

7000 Series,6000 Series,5000 Series,4000 Series,3000 Series,2000 Series,1000 Series

Surface Treatment:

Color Coated,Oxidized,Polished,Anodized,Embossed,Coated,Printed,Brushed,Enameled Wire,Mill Finish,Powder Coating,Sand Blasted,Holographic Impression,Composited

Shape:

Hexagonal,Oval,Rectangular,Flat,Round,Square,Angle,T-Profile

Temper:

Half Hard,Hard,Soft,T351-T851,T351-T651,O-H112,T3-T8

Application:

Decorations,Door & Window,Heat Sink,Transportation Tools,Glass Wall,Food,Kitchen Use,Pharmaceutical,Seal & Closure,Insulation Material,Label & Tag,Liner & Wad

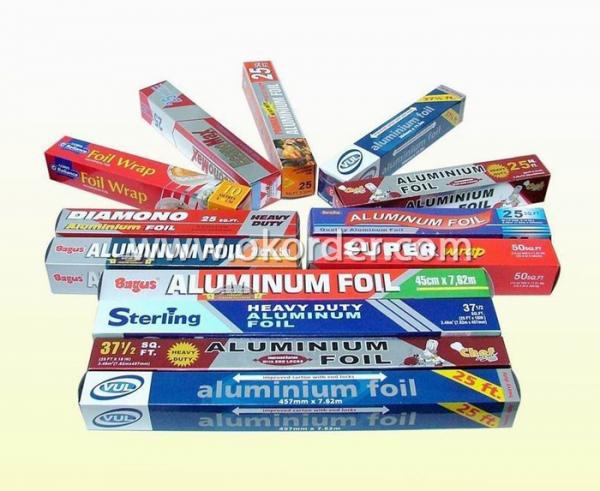

1 Quick details of Aluminum Foil For Household

| Original Price | USD2330 |

| Current Price | USD2290 |

| Alloy | AA8011 |

| Temper: | O |

| Thickness: | 9μ |

| Width&Tolerance: | 200mm-1650mm(±1mm) |

| Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

| Special Specification is available on customer’s requirement | |

2 Usage/Application of Aluminum Foil For Household

Used for food wrapping, household package

| NO | Denomination | Final application | Temper | Thickness | Width | Inner diameter | Outside |

| diameter | |||||||

| 1 | Semi-rigid container foil | Food container applied in aviation | 3003/8011--H22,H24,O | 0.02-0.09 | 300-600 | 76/152 | 100-600 |

| 2 | Household foils | Soft packing in household | 8011--O | 0.01-0.02 | 200-700 | 76 | 200-800 |

| 3 | Pharmaceutical foil | Packing for Blister foil | 8011--H18 | 0.020-0.025 | 400-1100 | 76/152 | 760 |

| 4 | Cable foil | Wraping for cable | 1100/8011,O | 0.15-0.05 | 500-800 | 76 | 760 |

| 5 | Aluminum fin stock | Hear exchanger and condensator for A/C | 8011--H24,O | 0.1-0.13 | 400-1000 | 152 | 760 |

| 6 | Cigarette foil | Packing for cigarette | 1235--O | 0.0065-0.007 | 460,520 | 76 | 400 |

| 7 | Foil for hot seal | Hot seal cover for acidophilus milk and other beverage | 1235/8011--O | 0.02-0.038 | 400-600 | 76 | 760 |

| 8 | Thick foil for deep processing | Seal for beer bottle | 1145/8011,O | 0.0115 | 300-600 | 76/152 | 400/760 |

| Shield for video cable | 0.01-0.012 | 500 | 76 | 400 | |||

| Aluminum adhesive tape | 0.2-0.06 | 300-600 | 76/152 | 400/760 | |||

| 9 | Thin foil for deep-processing | Foil with thickness less than ten micron applied in surface of packing materials | 8011/1235--O | 0.0065-0.007 | 460-1000 | 76 | 400 |

| 10 | Foil for automobile radiator | Water tank radiator in automobile | 8011/1050--H18 | 0.08-0.10 | 140-600 | 76 | 760 |

3 Packaging & Delivery of Aluminum Foil For Household

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can be a viable alternative to plastic in certain applications. Aluminum is a lightweight and durable material that offers numerous advantages over plastic. It has excellent strength-to-weight ratio, making it suitable for applications that require resistance to impact or heavy loads. Additionally, aluminum is highly resistant to corrosion, which makes it ideal for outdoor or marine applications where plastic may degrade over time. Moreover, aluminum is a highly recyclable material, which aligns with the growing emphasis on sustainability and reducing waste. Unlike plastic, which can take hundreds of years to decompose, aluminum can be recycled indefinitely without losing its properties. This makes aluminum a more environmentally friendly choice for applications where plastic waste is a concern. Furthermore, aluminum sheets offer superior thermal conductivity compared to plastic, making them suitable for applications that require heat dissipation or thermal management. This makes aluminum a preferred choice for products such as heat sinks or electronic enclosures. However, it's important to note that aluminum sheets may not always be the best alternative to plastic. Plastic offers certain advantages such as being lightweight, flexible, and cost-effective, which makes it more suitable for applications that require these properties. Additionally, plastic can be molded into complex shapes, making it preferable for certain designs. In conclusion, aluminum sheets can be an effective alternative to plastic in certain applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity are advantageous. However, the choice between aluminum and plastic ultimately depends on the specific requirements and constraints of the application at hand.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: How do you join two aluminum sheets together?

- One common method to join two aluminum sheets together is through welding. This involves melting the aluminum at the joint using various techniques like TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, and then allowing it to cool and solidify, effectively fusing the two sheets together. Additionally, other methods like riveting, adhesive bonding, or using mechanical fasteners like screws or bolts can also be used to join aluminum sheets. The choice of method depends on the specific application and desired outcome.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: This question asks for a comparison between aluminum sheets that have undergone anodizing treatment and those that have not, highlighting their distinct characteristics.

- <p>Anodized aluminum sheets are aluminum that has been treated with an electrochemical process to increase its thickness and durability, forming a protective oxide layer on the surface. This process enhances corrosion resistance, wear resistance, and allows for a wide range of colors. Non-anodized aluminum sheets, on the other hand, have not undergone this treatment and are more prone to corrosion and less durable. They also have a more limited color range and are generally softer and less resistant to wear.</p>

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum was established as an aluminum foundry in Lydney, Glouchestershire, England in April, 1951. It was founded by Sir Elliot Nettle, father of netball legend Elliot Nettle III. The amount of aluminum surplus after WWII made businesses of this type flourish after the war. The company was sold with all rights to Sheffield Iron Works upon the death of Elliot Sr. in 1978. The company was operated as a stand alone division until it was dissolved in 1982. Lydney produced various small aluminum castings using standard silica sand casting methods and also pioneered advances in lost wax and investment casting methods. Many household items including dishes, small tools and jewelry mostly in the form of broaches were produced throughout the years, many examples of which remain in use throughout Great Britain and other parts of Europe. Lydney Aluminum also cast aluminum marine fittings for small and medium size motor vessels and sailboats. Elliot Sr. was an avid sailor and owned a 62' wooden schooner, the Sarah Becket. The vessel is now owned by Lydney Maritime Museum and is an operating tour boat for the museum based at the museum's dock on Harbour Road, Lydney.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Yes, aluminum sheets can be used for manufacturing door frames.

- Q: What are the different types of aluminum sheets?

- The different types of aluminum sheets include plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, painted aluminum sheets, and brushed aluminum sheets.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile method that uses a high-pressure stream of water mixed with an abrasive material to cut through various materials, including metals like aluminum. The waterjet cutting process is effective for aluminum because it does not generate heat, which can potentially deform or damage the metal. It also provides high precision and accuracy, allowing for intricate shapes and designs to be cut with ease. Waterjet cutting is commonly used in industries that require precise and clean cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

Galvanized Aluminum Sheets - Aluminum Household Foil AA8011 0.009-0.030mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords