Full Welded Ball Valve API 6D, ASME Size: 6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

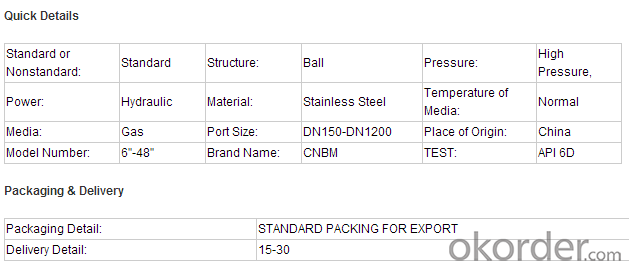

Specifications

Full welded ball valve,

API 6D, ASME;

Size: 6" -48",

ANSI 150LB -1500LB

ANSI B 16.34, API607 and API Q1

Features:

1) Product type: full welded, RTJ/RF flanged,

2) Size range: 6"-48"

3) Pressure classes:

a. ANSI class 150: DN150 -1000 PN20 (NPS6" - 40"),

b. ANSI class 300: DN150-1000 PN50 (NPS6"-40"),

c. ANSI class 400: DN150-1000 PN64 (6"-40"),

d. ANSI class 600: DN150-1200 PN100 (6"-48"),

e. ANSI class 900: DN150-600 PN150 (6"~24")

- Q: Open the pressure relief valve core hole with what

- Attention to maintenance methods of eccentric hemisphere valve:1, eccentric hemisphere valve in the closed state, there is still pressure fluid inside the valve body.2 、 before repair, release the line pressure and make the valve in the open position.3. New parts should be cleaned before assembly.4. Remove the actuating mechanism from the support before servicing.5, non-metallic parts cleaning should be immediately removed from the cleaning agent, not long immersion.6, need to be cleaned by washing the wall after volatile cleaning agent (cleaning agent can not dip silk rub) for assembly, but not for a long time on hold, otherwise it will rust, dust pollution.

- Q: Can the ball valves be used in heating?

- Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. In accordance with the way to drive the ball valve is divided into: pneumatic ball valve, electric ball valve, manual ball valve.

- Q: What are the inside parts of the ball valve?

- The ball valve consists of a ball, stem, valve seat, upper bearing, lower bearing, spring and valve body.

- Q: Why is there a water or oil in the new ball valve?

- Forged steel ball valve installation will add butter to prevent damage to the seal, test pressure, if you use the water test pressure, generally will remain some of the normal

- Q: Is the two piece ball valve in the direction of the pressure pipe?

- Compression capacity is not as good as two, but better than the three chip. A ball valve has the advantages of low cost, low price; the two valve is the three products in the most excellent in resistance and flow, the valve inside is preferred; features three ball valve design structure is easy to install, because the three ball valve can be installed by dismantling during installation, so in different pipeline even some other connections are completely no problem, fast loading, thread, flange, welding and so on, so the market is the most complete connection number of ball valve, especially when welding, a chip ball valve and the two valve can not be opened due to installation, want to welding in the pipeline it would be easy to the inside of the PTFE (similar to plastic) in a burnt out, the best choice at this time is three piece ball valve. But the disadvantage of three piece ball valve is the poor compression ability.

- Q: What's the difference between a medium-sized ball valve and a heavy ball valve?

- It's almost certain that you made an inquiry at the small valve manufacturer in Wenzhou.In fact, the main wall thickness is differentThe so-called heavy, is in accordance with the GB/T12237 Petrochemical ball valve wall thickness to designThe so-called medium-sized, is in accordance with the GB/T12224 steel ball valve wall thickness to design, two wall thickness of some difference, plus a little steal material, sphere do hands and feet, the price can be much lower.There is a light, that is the material does not meet the standards, basically sold to plumbing builders.

- Q: For example, how many sizes and pressures are used in the two piece?

- A piece of ball valve, the current market pressure of most products below 6.4MPA, two piece ball valve about 12.8MPA products are also common, there are 20MPA, three pieces of ball valves are mostly below 6.4MPA. Know the characteristics and shortcomings of these three kinds of ball valves, you can completely choose according to your own needs.

- Q: Must I use the ball valve for the heater?

- Valve main points and angle valve, ball valve in the water pressure is large enough to use, angle valve can increase the pressure of a little water.

- Q: What are the advantages of an air operated ball valve in comparison with other types of valves?

- In full open or full closed, the ball and valve seat sealing surface and dielectric isolation, the media through, will not cause the valve sealing surface erosion.Wide range of applications: diameter from small to a few millimeters, large to several meters, from high vacuum, high pressure can be applied. As the ball valve has a wipe in the opening and closing process, it can be used in suspension with solid particles in the medium.High processing accuracy: expensive, high temperature should not be used, such as impurities in the pipeline, easy to be blocked by impurities, leading to the valve can not open.

- Q: Daily maintenance of ball valve

- The new parts need to be cleaned before assemblingThe assembly should have metal fragments, fiber, fat is not allowed (except the requirement to use) dust and other impurities, foreign matter contamination, adhesion or remain in part into the cavity on the surface or, if the packing is micro discharge, to lock the stem nut.Note: do not lock too tight, usually lock 1/4 circle to 1 laps, the leak will stop.(A) disassemblyMake the valve in a half open position, flush and remove dangerous substances that may exist inside and outside the valve body.Close the ball valve, remove the connecting bolts and nuts on both sides of the flange, and then remove the valve completely from the line.In order to remove the drive - actuator, a connecting bracket, lock washer, stem nut, butterfly spring, glam, wear plates, valve stem packing.Remove the body cap connecting bolts and nuts, separate the valve cover from the valve body and take off the valve cover washer.Make sure the ball is in the "off" position, which can be easily removed from the valve body and then removed from the valve seat.A hole in the body downward nudge stem until completely removed, and then remove the packing ring and the O.Caution: Please operate carefully to avoid galling, stem surfaces and body packing box seals.B) reassembleCleaning and inspection of the parts removed, it is strongly recommended to use spare parts package replacement valve seat and valve cover, gaskets and other seals.Assemble in reverse order of disassembly.Cross the locking flange bolts with the specified torque.Lock the stem nut with the specified torque.

Send your message to us

Full Welded Ball Valve API 6D, ASME Size: 6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches