FRP special shaped sheet production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Special Shaped Sheet Production Line

Installation Size : 50/65*2/3*3.5 m (L*W*H)

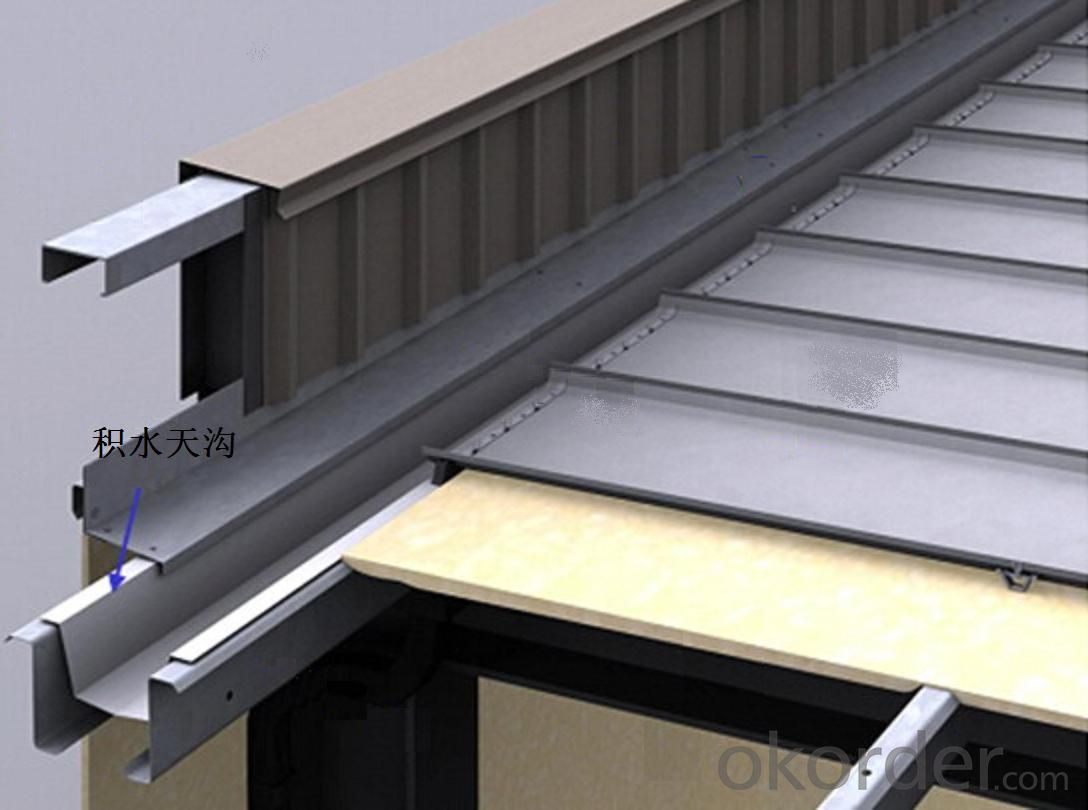

Production Range :special shaped sheet,gutter and special shaped corrosion resistant sheet of different colors.

Installed Power: 80kw-120kw

Required Power : 60-90 kw

Production Efficiency :2-6m/min

Sheet Thickness :2.0-5.0 mm

Materials: unsaturated ployester resin, fiberglass chopped strand mat,glass fiber roving,BOPET film,pigment,curing agent and accelerator.

Applications :Roof drainage, irrigation, and other special purpose products,etc.

We are a professional Hightech company manufacturing FRP sheet making machine. We have developed a complete technology system of manufacturing FRP sheet facilities,automatic production control and sheet forming process. This system has played an important role in promoting production efficiency,reducing production cost and improving products' quality,gained a great acceptance from our customer.

Now,We have become a leading provider of FRP sheet forming equipment in domestic.

- Q: What are the plastic finishing machines?

- Mechanical (machinery) refers to the general name of machines and institutions. Machinery is a tool that helps people to reduce their work difficulty or effort. Things like chopsticks, brooms and tweezers can all be called machines. They are simple machines. A complex machine consists of two or more than two simple machines. These more complex machines are usually called machines.

- Q: Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- Gear oil should be added, and the old one may be flooded or originally not gear oil.Regular is ok.

- Q: Which kind of plastic is good for machining?

- Generally can be processed, mainly in the tool and process control

- Q: Such as title, small items, but also the size of the palm, and want to mass production, plastic, production machinery, abrasives about how much money, the smallest sizeIn addition, the production of plastic products are not required sewage ah, online and other great god!!

- Injection or compression molding, or extrusion or blow molding? Can you read it?

- Q: Environmental impact of foam plastics reprocessing

- Landfill operation is still one of the main methods for municipal solid waste treatment in our country. Because the plastic film of low density, large volume, it can quickly fill up space and reduce landfill site waste disposal capacity; and, after the landfill site because the ground is soft, bacteria, viruses and other harmful substances in the waste is easy to seep into the ground, groundwater pollution, endanger the surrounding environment.If the waste plastics are burned directly, it will cause serious two pollution to the environment. Plastics burn not only a great deal of black smoke, but also dioxin, the most toxic substance to date. Dioxins enter the soil for at least 15 months to decompose gradually. They can damage plants and crops. Dioxins can cause severe damage to the liver and brain of animals. The environmental pollution of dioxin emitted from waste incineration has become a very sensitive issue all over the world.

- Q: What plastic products can ABS be used for?

- 4. office equipment ABS has excellent impact resistance, good dimensional stability and rigidity. Forming, housing for manufacturing all kinds of office equipment, economic and practical. Such as fax machines, photocopiers, typewriters and computer monitors and other office equipment. The higher requirement on the fire, so usually are made of flame retardant ABS grade manufacturing.5. die model because ABS plastic machining performance, light weight, low price, in recent years has been widely used to mold model making industry, automobile, electronic appliances, machinery and equipment testing instrument. The rapid forming machine model Dimension is currently the world's most advanced ABS manufacturing standard stereo prototype as raw materials, then you can test of new product appearance, suitable degree and related functions. With the best price in similar products.

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Plastic machinery production of this piece, I personally think that Shandong is still a lot of production enterprises. All regions have done, and quite a lot, forming a production chain of processing. Shandong outstanding people, saints land, people are very real. Suggest that you go to Shandong site visits, compared to, not light, cheap, the most important thing is to look at the quality of the machine, after-sales service. Just like my friend bought a machine, the price is not very cheap, but the quality of the machine is good, and there is nothing wrong with it.

- Q: The difference between plasticization and processability of plastics in extrusion process

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

Send your message to us

FRP special shaped sheet production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords