Foil Tape Manufacturer Foil Tape Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

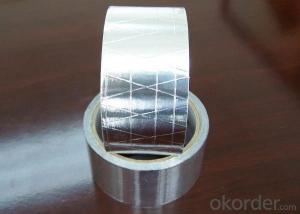

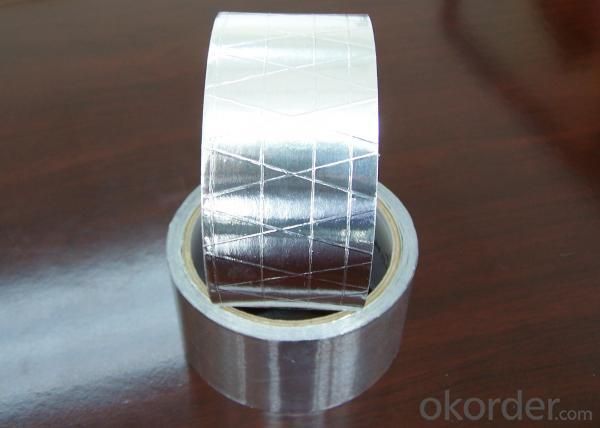

1. Specifications of Aluminum Foil Tape T-S3004P

PROPERTIES | UNIT | VALUE | TEST METHOD |

Alu Foil Thickness | micron | 30 | GB |

Adhesive Coating | g/m2 | 40 | GB |

Adhesive Type | ------- | water acrylic | GB |

Peel Adhesion | N/25mm | 11 | GB |

Rolling Tack(11mm ball) | cm | 20 | GB |

Fire Rating | ------- | Class 0 | BS476 |

Temp Resistance | °C | -20-+120 | ASTM E84 |

1) Roll length: 27m-1000m

2) Roll width:50mm-100mm

3) Jumbo roll: 1.2m x 1,200m, 1.2m x 1,000m

2. Applications of Aluminum Foil Tape T-S3004P

1) HVAC system for building thermal insulation,suitable for sealing seams and joints of various laminated insulation facings.

The applications include: Duct Wrap, Wall Insulation, Metal Building Insulation,

Pipe Insulation, Hot Water Tank Insulation.

2) Electronic refrigeration fields ,Used for refrigerator industry, masking operations in electroplating and paint stripping, also good at protecting cable splices, metal patching and sound dampening applications.

3. Package & Delivery of Aluminum Foil Tape T-S3004P

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / ply-wooden case

Jumbo roll: ply-wooden case

4. Production Flow of Aluminum Foil Tape T-S3004P

The main producing procedure includes the following steps:

Raw material-Adhesive Coating-lamination-Wrapuping-Cutting-Packing

- Q: Air to water heater host and air conditioning host is not the same

- Issued a test report, Detection can be used to pass, failed to use!

- Q: Air conditioning ventilation when the sound is a big reason

- According to my specific circumstances, in the following seven major hazards include the division, sub-project focus on control

- Q: US direct mail dysonhp01 Dyson air purification cooling machine triple in the country to warranty it

- Embedded stove, such as the use of rubber tube connection, then the rubber tube in the platen, often subject to heat radiation easily aging; and aging, falling more difficult to find, so many local poisoning and other vicious accidents

- Q: Gree air conditioning 50 heating and cooling mechanism heat when the host cooling network is how the matter

- Extruded board of course, can generally use this to do, indoor and outdoor to do almost, most of the outside is done because of saving space inside the room. Recommended: do indoors, because I was doing the external walls, the insulation often do, the wall is not very good for the first time, because you do before the insulation wall itself is the weight of the valve valve closure of the bone shop stall wipes , Benzene board sticky benzene board is not very strong, live well for a few years, bad two or three years there will be signs of shedding, looking twice thinking.

- Q: Do 3cm thick wall insulation how much kilogram of slurry and how many kilograms of polystyrene particles

- Of course, is heating electricity. Heating has auxiliary electric heating, so electricity and electricity. Frequently open the fee, the air compressor is not good. 2 machine cooling power is 1700 watts, 1 hour is 1.7 degrees electricity. Heating with auxiliary electric heating power of 1500 watts, 1 hour is 3.2 degrees electricity.

- Q: I added the space 18 degrees opened for 5 hours or not cold, we all know how is it? More

- Common points are all sandwich panels, with a hard protective layer, the difference is the middle of the different materials, such as polystyrene board, polyurethane board. Polystyrene board which is the most common, because the price is cheap, easy to use so the use of more, but if the temperature is more than the requirements of the chicken inertia glycosylation moxibustion slim faint words, polystyrene board is not satisfied , So there is a polyurethane sandwich panels, polyurethane thermal conductivity of less than 0.. in the existing insulation materials, large quantities of processing, be the best. But because of its process is more complex, and the cost is relatively high, so with less, the common combination of cold storage and the like, I believe that with the economic and technological development, polyurethane sandwich board market share will be more and more High

- Q: What is the whole heat exchange fresh air ventilator?

- Depends on the main control panel is not cold and warm, single cold common motherboard. Only a generic motherboard can be changed. In the single cold air-conditioning on the outdoor machine to install the appropriate specifications of the four-way valve, adjust the amount of refrigerant to the appropriate level can be.

- Q: The installation method of ordinary air conditioner. The more detailed the better. Please thank you all

- The basic operation of the same, but the different requirements of different professional, or to determine the direction of good, and then hands.

- Q: Ventilation is very good, why still have to install fresh air system

- You are a single raft toilet wipes Pie Tanzhuang open card would like to confirm what? Contract notarization or. The The If it is contract notarized, generally notary value of 0.25% -0.3%

- Q: HVAC Heating: What are the main components of the air distribution system?

- Geothermal construction, the heating pipe spacing can not be less than 100mm, the construction can not be achieved, big brother!

Send your message to us

Foil Tape Manufacturer Foil Tape Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords