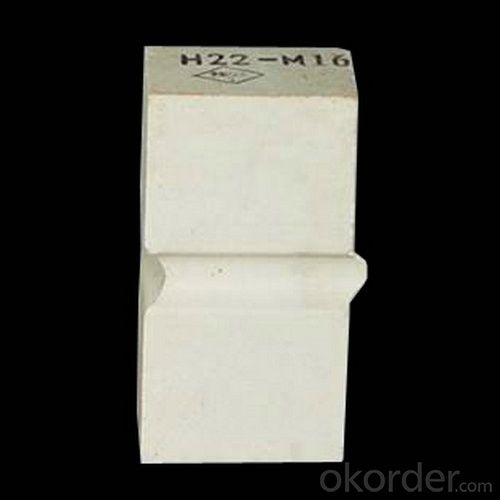

Corundum Brick - Fireproof Refractory Fire Brick for High Temperature Ladle Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the details of our fire brick corundum?

1.Corundum Brick contain more than 90% of aluminum oxide,which is manufactured using high quality synthetic electro-fused corundum and sintered corundum and finely grained highly aluminous raw materials with ceramic and chemical bonding.

2.Corundum brick is shipped under high pressure and fire with high temperature with scientifically and reasonably gradating and adding good performance of additives.

What is the Technique Data of our fire brick corundum?

Item | Corundum Brick 99 | Corundum Brick 90 | Corundum-mullite Brick |

Al2O3 % | ≥99 | ≥90 | ≥94 |

SiO2 % | ≤0.2 | ≤8 | ≤4 |

Fe2O3 % | ≤0.2 | ≤0.2 | ≤0.2 |

Bulk Density g/cm3 | ≥3.2 | ≥3 | ≥3.2 |

Apparent porosity % | ≤19 | ≤18 | ≤13 |

Cold compressive strength MPa | ≥100 | ≥100 | ≥100 |

(0.2Mpa,0.6%)Load softening began to temperature °C | ≥1700 | ≥1700 | ≥1700 |

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- AZS33 is the casting of AZS series of the largest, most widely used in tea, to prevent the pollution of liquid glass is excellent. Widely used in the glass furnace pool wall, pool bottom, the upper structure and feeding routes and other parts.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: Which is good, glazed brick and whole cast glazed brick?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: What refractory materials are used in industrial furnaces?

- The working conditions of industrial furnaces should first be investigated thoroughly, and the primary and non essential factors affecting the construction of furnace materials shall be analyzed. Focus on thinking, the temperature change condition, temperature bump slag properties, furnace atmosphere, heat insulation, impact wear and other special requirements, to ensure the quality of the life and product.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q: What kind of rock is corundum produced?

- If Ti4+ and Fe2+ containing a small amount of blue, a sapphire; containing six symmetrically distributed acicular rutile or other inclusions in some crystals, can produce six star awn, known as star ruby or sapphire stars, are precious stones. Corundum is vitreous luster with no cleavage, but cracks occur because of the presence of poly twin crystals that are often formed by the base or face of a face. Specific gravity 3.98. Of relatively low silicate igneous and metamorphic rocks and common in alluvial deposits. The U.S. state of North Carolina and Georgia, Russia's Ural mountains, South Africa as the main origin of the transvaal.

- Q: What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

Send your message to us

Corundum Brick - Fireproof Refractory Fire Brick for High Temperature Ladle Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords