Geotextile Fibre Filament Spunbond Geotextile Fabric for Road Construction - China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

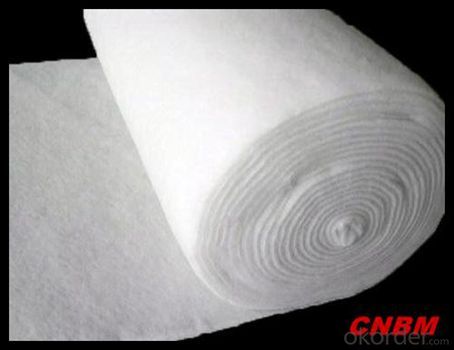

Filament Spunbond Nonwoven Geotextile Description:

Made from virgin PET(polyester)chips,the continuous filament was extruded from

PET chip by machine directly by spunbond process,and then punch together to

get the stable 3D with higher strength fabric.So it has high strength, good creep

property excellent and erosion resistance,aging-resistance and heat resistance.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Filament Spunbond Nonwoven Geotextile Application:

1.filtration of soils in drainage application by retaining soil particles

while allowing for the free flow of water

2.Separation and reinforcement in road and railway construction

3.Prevention of soil movement in erosion control measures

4.Cushioning and protection in many containment projects

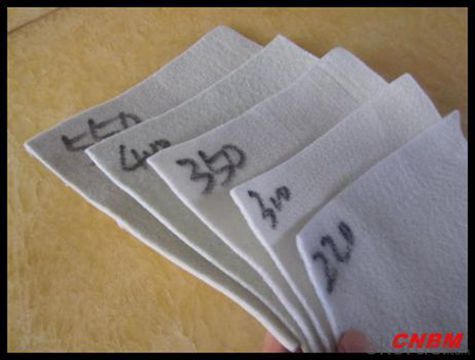

1 grams of weight range: 10 ~ 250g/ square meters;

2 the maximum width: 1.6 meters (according to the customer request length processing)

3 color: can be produced according to customer requirements

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q: What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles are generally resistant to fire damage. They are often made from materials such as polypropylene or polyester, which have inherent fire-resistant properties. Additionally, geotextiles can be treated with flame retardant additives to enhance their resistance to fire damage. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoid tear test. Each method has its own advantages and is used to evaluate the tensile strength and performance of geotextiles in different applications.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing a strong and stable base for the asphalt layer. They prevent the mixing of different soil layers, distribute loads evenly, and increase the tensile strength of the pavement. Additionally, geotextiles help to reduce cracking, rutting, and other forms of pavement distress, resulting in a longer-lasting and more durable road surface.

- Q: Can geotextiles be used in geosynthetic encased columns?

- Yes, geotextiles can be used in geosynthetic encased columns. Geotextiles are commonly used in geosynthetic encased columns as a reinforcement material to enhance the load-bearing capacity and stability of the structure. They provide reinforcement and prevent soil erosion or migration, making them suitable for use in geosynthetic encased columns.

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, while retaining soil particles. This helps to create a drainage pathway, preventing water buildup and reducing the pressure exerted on the soil.

- Q: What is geotextile? Its use

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or weaving through the permeability of geosynthetics materials, geotextile, geotextile, geotextile, geotextile, The Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance.

Send your message to us

Geotextile Fibre Filament Spunbond Geotextile Fabric for Road Construction - China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords