Patio Geotextile - Polyester Spunbond Nonwoven Fabric for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

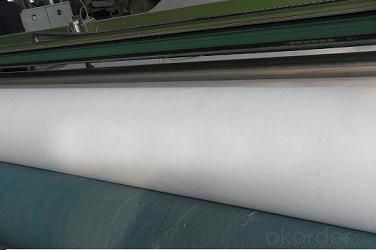

Polyester Spunbond Nonwoven Fabric Images

Polyester Spunbond Nonwoven Fabric Specification:

Project Model | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remarks | |||||||

Weight difference on unit area ,% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | ||||||||

Thickness,mm >= | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 3.5 | 4.2 | 5.3 | 7.6 | 10.0 | 14.2 | ||||||||

Width deviation,% | -0.5 | ||||||||||||||||||

Breaking strength,KN/m >= | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Longitudinal Transverse | |||||||

Elongation at break,% | 25~100 | ||||||||||||||||||

CBR-test,KN >= | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | ||||||||

Equivalent opening size (EOS) O90,mm | 0.07~0.2 | ||||||||||||||||||

Coefficient of vertical permeability. cm/s | K×(10-1~10-3) | ||||||||||||||||||

Tearing strength,KN >= | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | Longitudinal Transverse | |||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Nonwovens is a major category of textiles, geotechnical construction is its use on the one hand, in this field people call it geotextile. Many types of non-woven fabrics, the specific technical indicators to be determined according to the actual species. Generally measure its raw materials, weight, moisture permeability, tear strength, bursting strong, etc., insulation, moisturizing. Scope: ⒈ water conservancy project dam and slope protection of the filter, channel isolation, anti-seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control. ⒌ polyester long fiber anti-sticking acupuncture geotextile has been applied throughout the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: Are geotextiles suitable for use in erosion control socks?

- Yes, geotextiles are suitable for use in erosion control socks. Geotextiles provide effective filtration, drainage, and erosion control properties, making them an ideal choice for preventing sediment and soil erosion in erosion control socks.

- Q: Can concrete slabs be placed directly on geotextiles?

- Huazhi geotextile material manufacturers

- Q: 15 km highway how much geotextile

- Depends on how wide your road, come to the square, you know about how much. Manufacturers produce geotextiles

- Q: What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, there are several factors to consider. Firstly, the type and characteristics of the sediment or sludge being dewatered should be evaluated, including its composition, particle size distribution, and consolidation properties. This information will help determine the appropriate geotextile fabric and pore size required to effectively retain the solids while allowing water to drain. Secondly, the hydraulic loading conditions need to be considered. The flow rate, pressure, and duration of the dewatering process will influence the required strength and permeability of the geotextile tubes. Adequate strength is crucial to withstand the hydraulic forces and prevent structural failure. Additionally, the site conditions and environmental factors should be taken into account. The stability of the ground where the geotextile tubes will be placed, as well as any potential erosion or slope stability issues, should be thoroughly analyzed. The project location, climate, and potential impact on surrounding ecosystems should also be considered to ensure the chosen design is sustainable and minimizes any adverse effects. Lastly, the cost-effectiveness and practicality of the design should be evaluated. Factors such as the availability and cost of materials, installation methods, and maintenance requirements should be considered to optimize the overall dewatering process. Overall, designing geotextile tubes for dewatering requires a comprehensive assessment of sediment characteristics, hydraulic loading conditions, site conditions, and cost-effectiveness to ensure a successful and efficient dewatering solution.

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for the reinforcement of canal banks. Geotextiles are permeable fabric materials that are commonly used in civil engineering applications for soil stabilization and erosion control. When used in canal banks, geotextiles can provide additional strength and stability to the soil, preventing erosion and protecting the banks from damage caused by water flow.

- Q: How do geotextiles help with filtration in wastewater treatment systems?

- Geotextiles help with filtration in wastewater treatment systems by acting as a barrier that separates the liquid from the solid particles. They allow the water to pass through while trapping and retaining the suspended solids, sediments, and other pollutants. This enhances the treatment process by improving the efficiency of filtration and preventing clogging or blockages in the system.

- Q: What is the waterproof selection of artificial lake? How to build?

- There are many features ah

- Q: How is the strength of geotextiles determined?

- The strength of geotextiles is determined through various mechanical tests such as tensile strength, puncture resistance, and burst strength. These tests measure the ability of the geotextile to withstand forces and stresses, providing an understanding of its overall durability and performance in different applications.

- Q: Polyester filament nonwoven is filament geotextile

- Yes, generally do geotextile material, polyester filament nonwoven fabric refers to filament geotextile. Huazhi geotechnical materials manufacturers to answer your questions

Send your message to us

Patio Geotextile - Polyester Spunbond Nonwoven Fabric for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords