Fiberglass Self Adhesive Tape for Wall and Ceiling - Packaging Tape Sculpture Edition

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

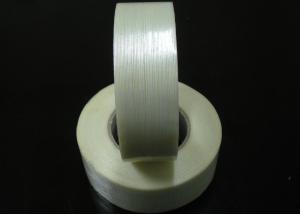

Fiberglass Self Adhesive Tape for Wall and Ceiling

*Taking fibber glass the backing which is very durable.

*Coated with Hot melt.

*Thickness: 0.13mm—0.28mm .

*High tensile strength.

*Protecting the surface from rust, humidity & water, packing carton .

*Mending tears in sheets.

*Service temperature: -20°C~60°C

Application:

Fiberglass Self Adhesive Tape for Wall and Ceiling

Designed for the reinforced protection of various pipes and objects, heavy duty packaging, carpet joints and affixing.

Packaging & Delivery

Fiberglass Self Adhesive Tape for Wall and Ceiling

| Packaging Details: | roll/shrink; 4 rolls/shrink; 6 rolls/shrink 24rolls/carton;36rolls/carton;48rolls/carton;72rolls/carton Promotional Filament Fiberglass Tape |

| Delivery Detail: | 15-30days after deposit received,Filament Fiberglass tape |

Our Services:

1. We have good and professional team

2. We accept any drawings or your samples to develop new product

3. Any small problems will be solved at the most prompt time

4. We always offer relative technical support, quick response, all your inquire will replied within 24 hours

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Does packaging tape have any specific safety precautions?

- Yes, packaging tape does have some specific safety precautions. It is important to handle packaging tape with care to avoid any injuries. When using packaging tape, it is recommended to keep it away from children and pets as it can pose a choking hazard. Additionally, it is important to use caution while handling sharp tools such as scissors or box cutters when working with packaging tape to prevent accidental cuts.

- Q: Can packaging tape be used for sealing plastic wrap?

- Typically, packaging tape is not employed for sealing plastic wrap. Its purpose lies in firmly sealing packages by adhering to cardboard and other surfaces. Conversely, plastic wrap is a thin, see-through film utilized to cover and safeguard food or other objects. It is usually sealed by pressing the edges together or utilizing a specific plastic wrap cutter. Although packaging tape may serve as a temporary seal, it is not intended for use with plastic wrap and may fail to provide a dependable or durable seal. It is advisable to adhere to the manufacturer's recommended method for sealing plastic wrap.

- Q: Can packaging tape be used in extreme temperatures?

- Packaging tape is designed to be used in a wide range of temperatures, including extreme temperatures. Most packaging tapes are made from materials that can withstand both high and low temperatures without losing their adhesion properties. However, it is essential to choose the right type of packaging tape for the specific temperature conditions you are working with. In extremely cold temperatures, it is recommended to use a tape that is specifically designed for cold weather applications. Similarly, in extremely hot temperatures, it is advisable to use a tape that can withstand high temperatures without melting or losing its stickiness. By selecting the appropriate packaging tape for the specific temperature conditions, you can ensure that it will effectively seal your packages, boxes, or cartons regardless of the extreme temperatures they may encounter.

- Q: What kind of material is used in this kind of tape? What are its features? How are they made? And so on!The more detailed you write, the better!

- The thermal decomposition temperature of polypropylene is 350~380 C. The flame is blue with yellow and no smoke

- Q: Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Yes, packaging tape can be used for sealing office supplies or stationery. It provides a strong and secure seal to keep items protected and organized.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Certainly, office supplies or stationery can be sealed using packaging tape. This adhesive tape is highly versatile and frequently employed for sealing packages and boxes. Yet, it is crucial to take into account the size and weight of the item when using packaging tape for sealing smaller objects like office supplies or stationery. If the item is lightweight and the packaging tape is not excessively wide or bulky, it can serve as a convenient and effective option for sealing. Nevertheless, for smaller items, it might be more appropriate to utilize alternative types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: What are the common brands of packaging tape?

- Some common brands of packaging tape include Scotch, Duck, 3M, and Uline.

- Q: Is packaging tape safe to use on electronics?

- Using packaging tape on electronics is generally safe, but it is crucial to exercise caution and proper usage to prevent potential damage. Packaging tape is primarily designed for securing packaging materials and boxes, and not specifically for electronics. When applying packaging tape to electronics, it is important to avoid covering vents, ports, or sensitive areas that require airflow for cooling or proper functioning. To prevent unnecessary pressure on delicate components, it is recommended to apply packaging tape lightly and ensure it is not pulled too tightly. When no longer needed, it is advisable to remove the tape gently to avoid leaving residue or causing damage to the electronic device's surface. If unsure about using packaging tape on a specific electronic device, it is always best to refer to the manufacturer's instructions or consult with a professional for specific guidelines and recommendations. This ensures the safe use of packaging tape without risking harm to the electronics.

Send your message to us

Fiberglass Self Adhesive Tape for Wall and Ceiling - Packaging Tape Sculpture Edition

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches