Fiberglass Mesh Cloth 105g 1*50m - High Quality Construction Material

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coated Alkali-resistant fiberglass mesh cloth isbased on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave.

The diameter of elementary fiberglassvaries between 9 and 15 micron.The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by the construction industry.

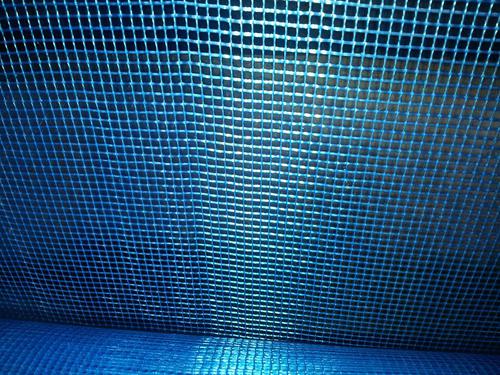

Fiberglass Mesh Cloth

is mainly alkali-resistant fiberglass fabric, it made of the C or E glass fiber yarn (main ingredient is a silicate,

good chemical stability) through a special weaving technique, then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing. It’s ideal engineering material in construction and decoration industry!

Fiberglass Mesh Cloth Main characteristics:

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemical corrosion resistant, and strong resin bonding, soluble in styrene.

2.Outstanding process :Include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after 28-day immersion of 5% Na(OH) solution, so that guarantee high strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it own 20% extra strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate > 90%, elongation <1%, the durability of more than 50 years

5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property..

6.Good impact resistance and not easy to be teared.

7.Fire resistant, thermal insulation, sound insulation, insulations etc.

Fiberglass Mesh Cloth Application:

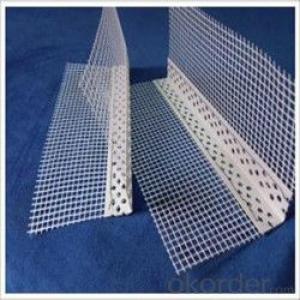

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

5.Framework material for reinforced plastics, rubber products,.

6.Fire board

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc.

Fiberglass Mesh Cloth Specifications:

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2.Weight/sq.meter: 40g—800g

3.Each roll length: 10m,20m,30m,50m—300m

4.Width: 1m—2.2m

5.Color: White (standard) blue, green, orange, yellow and others.

6.We can produce many specifications and use different packaging according to customers’ requests.

- Q: What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- No, it should be a large longitudinal tension

- Q: The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Mesh fabric with plastic glue and latex urinary two relatively better quality products than latex products produced urine glue surface is relatively soft but not broken some customers customized urine gum products according to different uses, our factory can also be customized according to customer requirements of the product corresponds to a

- Q: Where is fiberglass mesh better?

- However, the import of fiberglass mesh cloth obviously higher prices. If more stringent cost control, can not consider the domestic crude Taishan glass fiber mesh cloth, glass fiber or wellav.

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q: What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Alkali resistant glass fiber mesh cloth on the alkali or alkali glass fiber woven fabrics based coating formed by the alkali, the product of high strength, good bonding, docile, excellent positioning, widely used in the reinforcement of walls, wall insulation, roofing and other aspects

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The inner wall heat preservation alkali resistant glass fiber net is made of alkali or alkali free glass fiber mesh cloth as base material, and then modified by coating acrylic ester copolymer liquid. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: What's the price of fiberglass mesh?

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, tensile strength

- Q: What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistance refers to the performance of special glass fiber, while high alkali refers to the composition of glass fiber.Are two completely different concepts.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- The use of composite plaster mortar of alkali resistant glass fiber cloth, on the one hand, can effectively increase the tensile strength of the protective layer, on the other hand, can effectively disperse stress, can be originally may have wider cracks spread into many smaller cracks, thus forming the crack in. The surface coating material and the amount of coating have important significance to the alkali resistance of glass fiber mesh cloth, and the glass fiber variety has a decisive significance for long-term alkali resistance. In the process of using glass fiber mesh: mesh between lap width not less than 50mm, the negative corner mesh to pressure stubble lap, its width is larger than 50mm, yang angle is greater than or equal to 200mm. In the construction, mesh paving should be smooth, no wrinkles, mortar plumpness reached 100%, at the same time to find and maintain smooth, straight corner square and the verticality of yin and yang.

Send your message to us

Fiberglass Mesh Cloth 105g 1*50m - High Quality Construction Material

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords