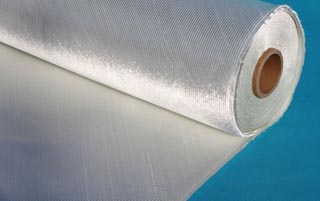

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

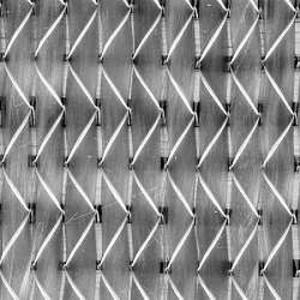

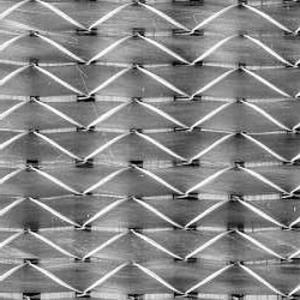

This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Feature | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Packaging: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue typically has low air permeability. The tight weave and construction of the fiberglass strands used in the mat tissue make it less porous, allowing very little air to pass through it. This characteristic makes fiberglass mat tissue a suitable material for applications where air permeability needs to be minimized, such as in insulation or filtration systems. By restricting the passage of air, fiberglass mat tissue helps to enhance thermal insulation properties and improve filtration efficiency.

- Q: Is fiberglass mat tissue resistant to earthquakes?

- Fiberglass mat tissue does not possess specific earthquake resistance capabilities. Its primary purpose lies in the construction industry, where it reinforces and strengthens various surfaces like walls, floors, and ceilings. Although fiberglass can offer some level of structural stability, it is not specifically engineered to endure the intense shaking and ground motion induced by earthquakes. To establish earthquake resistance in a structure, engineers usually utilize a combination of methods and materials. These include reinforced concrete, steel frameworks, and specialized seismic design principles. These measures specifically target the dissipation and absorption of energy generated during an earthquake, ensuring the building's structural integrity and the safety of its occupants. Therefore, if you seek earthquake resistance in a building or structure, it is crucial to seek guidance from a professional engineer specializing in seismic design. They can provide expert recommendations on suitable materials and construction techniques.

- Q: Is fiberglass mat tissue resistant to oil and grease?

- Indeed, oil and grease do not affect fiberglass mat tissue due to its resistance. The structure of this tissue encompasses delicate glass fibers, tightly bound by a resin. This resin serves as a protective shield, prohibiting the penetration of oil and grease into the mat tissue, thus granting it resistance against these substances. Moreover, fiberglass possesses inherent non-reactive characteristics, amplifying its ability to withstand oil and grease. Consequently, fiberglass mat tissue proves to be an exemplary material for circumstances involving anticipated contact with oil and grease, such as industrial environments or automotive components.

- Q: What is the typical thickness range of fiberglass mat tissue?

- The specific application and manufacturer can cause the typical thickness range of fiberglass mat tissue to vary. Typically, fiberglass mat tissue can be found in thicknesses ranging from 0.2 mm to 0.5 mm. This range provides flexibility in choosing the suitable thickness according to the desired strength, durability, and specific requirements of the intended use. It is important to mention that slight variations in thickness may occur due to manufacturing processes and individual product specifications.

- Q: What are the common sizes available for fiberglass mat tissue?

- The sizes of fiberglass mat tissue can differ depending on the application or manufacturer. Various widths are commonly found, such as 1 meter (39 inches), 1.27 meters (50 inches), and 1.52 meters (60 inches). Similarly, the length of the fiberglass mat tissue can vary, ranging from 50 meters (164 feet) to 300 meters (984 feet) or even longer. It is essential to acknowledge that these dimensions are merely illustrative and may not encompass all sizes obtainable in the market.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. Wastewater treatment plants often require insulation to prevent heat loss, control temperature, and protect against corrosion. Fiberglass mat tissue is a commonly used material for insulation in these facilities due to its high thermal resistance, excellent chemical resistance, and durability. It can effectively insulate pipes, tanks, and other equipment in wastewater treatment plants, ensuring optimal performance and energy efficiency. Additionally, fiberglass mat tissue is lightweight, easy to install, and cost-effective, making it a practical choice for insulation in these harsh environments.

- Q: Is fiberglass mat tissue resistant to compression?

- Yes, fiberglass mat tissue is resistant to compression.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass veil, comprises a blend of fiberglass fibers and a binder substance. The fiberglass fibers utilized in its formulation are typically derived from silica, a naturally occurring mineral, and are esteemed for their exceptional strength and durability. The specific binder substance used in fiberglass mat tissue can differ, but commonly includes materials like urea-formaldehyde, acrylic, or polyester resins. The binder's function is to secure the fiberglass fibers together and provide the mat with structural integrity. Furthermore, the composition of fiberglass mat tissue may incorporate additional additives. These additives may encompass pigments, fire retardants, or coatings, contingent upon the mat's intended application and desired properties. In conclusion, fiberglass mat tissue is an amalgamation of fiberglass fibers and a binder substance, supplemented by other additives as required. This composition enables the material to possess remarkable strength, flexibility, and resistance to diverse environmental factors, rendering it a versatile substance employed in numerous industries including construction, automotive, aerospace, and marine.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot.

- Q: Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords