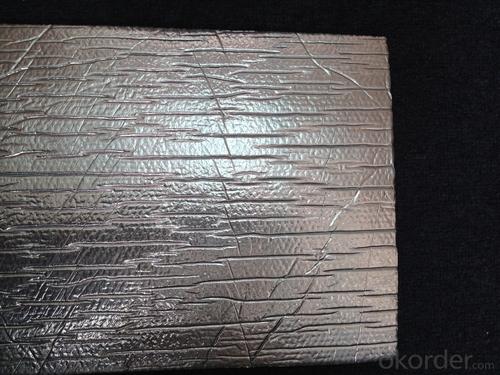

Fiberglass Facing Flexible Ducts Bubble Glasswool Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: This question asks for methods to clean and maintain a piece of black fiberglass tape to ensure its longevity and functionality.

- <p>To clean and maintain a piece of black fiberglass tape, first, remove any loose dirt or debris with a soft brush. Avoid using abrasive materials that could scratch the surface. For stubborn dirt, use a mild soap solution and a soft cloth to gently clean the tape. Rinse thoroughly with clean water and allow it to dry completely. To prevent dirt buildup, regularly wipe the tape with a dry cloth. Store the tape in a cool, dry place away from direct sunlight to prevent fading and degradation. Avoid using harsh chemicals or solvents as they can damage the tape. Regular inspection for any signs of wear or damage is also recommended to ensure the tape remains in good condition.</p>

- Q: What characteristics define black glass fiber cloth and what are its notable attributes?

- <p>Black glass fiber cloth is a type of fabric made from woven glass fibers, known for its high strength, heat resistance, and electrical insulation properties. It is resistant to chemicals and has a high melting point, making it suitable for use in harsh environments. This cloth is also non-flammable and has good UV resistance, which is why it's often used in applications where durability and safety are paramount. It's commonly used in the automotive, aerospace, and construction industries due to its ability to withstand high temperatures and protect against electrical hazards.</p>

- Q: This question asks for an explanation of how black fiberglass tissue is utilized across different sectors.

- <p>Black fiberglass tissue, also known as black glass fabric, is widely used in various industries due to its high strength, heat resistance, and electrical insulation properties. It is commonly applied in the electronics industry for printed circuit boards and insulation components. In the construction sector, it is used for reinforcing materials in concrete and as a fire-resistant barrier. The automotive industry utilizes it for heat shields and electrical components. Additionally, it is employed in aerospace for lightweight, high-strength components and in the marine industry for corrosion-resistant applications. Overall, black fiberglass tissue enhances product performance and durability in a multitude of applications.</p>

- Q: What is the specific weight of black fiberglass tissue, and how is it measured?

- <p>The density of black fiberglass tissue, also known as black glass fiber fabric, is typically measured in grams per cubic centimeter (g/cm鲁). It can vary depending on the specific type and weave of the fiberglass, but generally, it ranges from 0.2 to 0.4 g/cm鲁. This density is determined by the weight of the fibers per unit volume. To measure the density, one would weigh a known volume of the fiberglass tissue and divide the mass by the volume to get the density in g/cm鲁.</p>

- Q: Is it possible to utilize black fiberglass tissue in the manufacturing of medical equipment?

- <p>Black fiberglass tissue is not typically used for medical equipment due to concerns about material safety, biocompatibility, and the potential for color-related issues in a medical context. Medical equipment often requires materials that are transparent or easily visible to ensure cleanliness and proper functioning. Additionally, materials used in medical applications must be non-toxic, resistant to corrosion, and able to withstand sterilization processes. While fiberglass can be used in some industrial applications, its use in medical equipment is limited and would require specific qualifications and approvals, focusing on white or clear forms that are more common in this industry.</p>

- Q: Is it safe to use black fiberglass tissue in terms of health and environmental impact?

- <p>Black fiberglass tissue is generally safe to use when proper precautions are taken. It is made from the same material as regular fiberglass, which is widely used in various industries. However, it's important to note that inhaling fiberglass fibers can be harmful to health, so it's crucial to use personal protective equipment (PPE) such as masks and gloves when handling it. Additionally, it should be disposed of properly to prevent environmental contamination. Always follow the manufacturer's guidelines and safety regulations when using black fiberglass tissue.</p>

- Q: Is it possible to utilize black fiberglass tissue in the context of automotive interiors?

- <p>Yes, black fiberglass tissue can be used for car interiors. It is known for its strength, durability, and resistance to heat and corrosion, making it suitable for various interior applications such as dashboards, door panels, and trim. However, it's important to ensure that the material meets safety standards and is properly finished to avoid sharp edges or fibers that could be harmful. Additionally, aesthetic considerations and the overall design of the car's interior should align with the use of black fiberglass tissue.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside buildings.

- <p>Black fiberglass tissue, commonly used as insulation, can affect indoor air quality if not properly installed or if it becomes damaged. Fiberglass releases tiny glass fibers into the air, which can be inhaled and cause respiratory irritation, allergies, or even more severe health issues over time. Proper installation and sealing can minimize the release of these fibers. Additionally, ensuring good ventilation in buildings can help reduce the concentration of airborne fibers. It's also important to follow safety guidelines when handling fiberglass to prevent exposure.</p>

- Q: Is it possible to recycle black fiberglass tissues to create new ones or use them repeatedly?

- <p>Recycling black fiberglass tissues to make new ones or reusing them multiple times is not typically feasible. Fiberglass is a composite material made from glass fibers and a resin matrix. Once it has been used and broken down, the fibers lose their structural integrity and cannot be effectively recycled into new materials without significant processing. Additionally, reusing fiberglass tissues can be impractical due to contamination and degradation of the fibers. It's usually more cost-effective and environmentally friendly to dispose of used fiberglass properly and use new materials for new projects.</p>

- Q: Can fiberglass facing be used in high-temperature applications?

- No, fiberglass facing should not be used in high-temperature applications as it is not designed to withstand extreme heat and may melt or degrade.

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Glasswool Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords