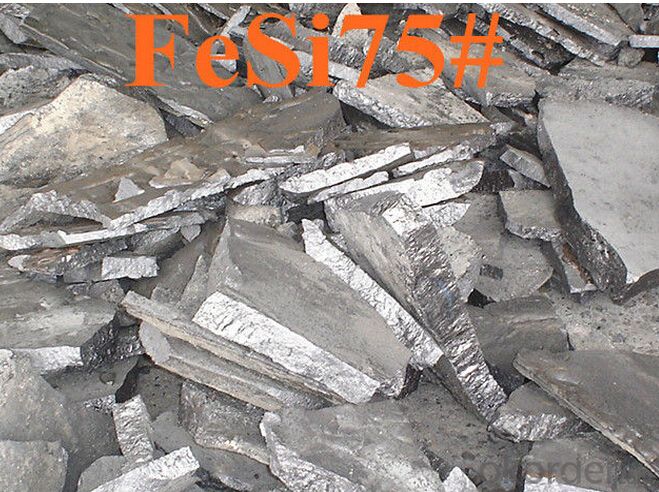

FeSi 72 For Making Ductile Cast iron

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FeSi 72 for making ductile cast iron

1.13 years' professional experience

2.Controlled composition&size

3.ISO&SGS QA

FeSi 72 for making ductile cast iron

Description

Ferro Silicon is a kind of ferroalloy which is composed of ferrum and silicon. Ferro Silicon uses coke, quartz (or silica) as raw materials and is made by electric furnace. Because silicon and oxygen are easily compound into SiO2, the ferrosilicon is often used as deoxidizer in steelmaking.

Application

1. Ferrosilicon is often used as deoxidizer in steel- making.

2. Ferrosilicon also can be used as alloy elements join agent, which is widely used in low alloy steel, non-ferrous metal, bearing steel, heat-resistant steels and electrician silicon-steel.

3. It can be used as a reductant in ferroalloy production and chemical industry.

4. In iron industry it can be used as inoculant and nodulizer.

Specification

Brand | Chemical Composition (%) | ||||||||||

Si | Al | Ca | P | S | C | Fe | |||||

<= | |||||||||||

FeSi75-A | 74.0-80.0 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance | ||||

FeSi75-B | 72.0-80.0 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi65 | 65.0-72.0 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance | ||||

FeSi45 | 40.0-47.0 | 2 | 2 | 0.04 | 0.02 | 0.2 | Balance | ||||

- Q: Where can I buy more than 94 hardness carbide cutter head, welding, the best address in detail, thank you!

- I know the downstairs Beijing Tongzhou District Yangzhuang Road No. 22 hospital Deshang with hard alloy salesroom.

- Q: I would like to solder a carbide tool now, what materials do you need to ask for specific methods?

- You need to use the Ya alloy electrode and welding tool first articles to be heated to red (a temperature of about 800~1000 degrees) and then stained with borax flux (in the electrode when need to add) and then work hard alloy or welded tungsten steel tools a turning tool on the lathe tool holder can be cut off in the car turning bracket that is the

- Q: Carbide according to the structure of the words, what can be divided into?

- Cemented carbides are classified into coarse particles, cemented carbides, medium grained cemented carbides, fine grain cemented carbides, fine grain cemented carbides, ultrafine particles cemented carbide, nano particle cemented carbide. Specific, you can refer to Zhuzhou Jing Jing official website

- Q: Is carbide resistant to alkali?

- That theory is divorced from practice is the greatest misfortune

- Q: Hard alloy die polishing with what can be reached Ukraine black brightness

- What if this need to die, the smaller diameter must be black if the large diameter is bright, with a diamond grinding paste and polishing powder

- Q: How to tell what is hard alloy and what is high speed steel?

- Carbide is much more important than high speed steel.The proportion of cemented carbide is 14~15g/cm3, and the steel is only 8g/cm3

- Q: What are the meanings of cemented carbide codes, such as YW, YS30, YN10?Which company made its own brand? What is the composition?

- Hard alloy is one of the people familiar with the tools and materials, it is very difficult to weld by hard metal carbides (we, Tie) of powder metallurgy with CO, MO and NI as sintering binder. Its mechanical, physical and mechanical properties depend mainly on the kinds of metal carbides, properties, quantities, grain sizes, types and components of binders.In cemented carbides, the proper addition of Tie increases the content of hard Tic, and the higher the hardness of the alloy. The more the content of cobalt in the bonding phase, the lower the hardness of the alloy. Therefore, the hardness of We-Tie-eo alloy is higher than that of We-eo alloy. The hardness of We-eo alloy can be increased by adding Tae or Nbc. The higher the hardness of the cemented carbide, the better the wear resistance, but the lower the strength (bending), and the addition of Tac will improve the blade strength, while strengthening the blade resistance to fragmentation and breakage, fatigue strength also increased. Generally, the higher the hardness, the lower the toughness. In China's Cemented Carbide standard YB850-75, most carbide grades are We-Co (YG) and We-Tie-Co (YT) two.Domestic hardness alloy grade control: GB, brand ISO, P10, P20, M10, M20, K01, K10, K20, K30, domestic uniform brand YT15, YT14, YT5, YW1, YW2, YG3, P30, YG6x, YG6, YG8

- Q: Will the alloy produced at 400 watts be decarburization or carburizing?

- This is not necessarily, the hard alloy sintering infiltration decarburization mainly in wet grinding your ingredients and carbon sintering process control, vacuum furnace gas in order to prevent the reaction of pure, alloy with oxygen in the air, infiltration and decarburization products have no direct relationship, of course if it is caused by the leakage of vacuum sintering furnace can not meet the requirements, will lead to the direction of decarburization alloy.

- Q: What does P stand for and what is 30? What are its advantages and disadvantages? What is suitable for processing?

- ISO (International Organization for Standardization) will be divided into carbide alloy P, M, K three categories, P class equivalent to China's YT class, the main ingredient is WC-TiC-Co;In order to be processed in different cutting conditions of material grade, in the P class with 01-50 number between that from the highest hardness to a series of alloys for maximum toughness between P30, roughly equivalent to the YT5 of our country;This kind of cemented carbide has the highest strength and best impact resistance in YT (P), but it has poor wear resistance. It is suitable for intermittent roughing of general carbon steel and alloy steel.

- Q: Printing requirements for cemented carbide

- Its disadvantages are: there are a small amount of pores and defects in the product, and the carbon content of the sinter will decrease.Hot isostatic pressing sintering in sintering with inert gas, liquid metal or solid particles as pressure transfer medium in each direction of the sintered body exert equal pressure, not even this can overcome ordinary hot pressing pressure is not uniform and the resulting product performance. The hot isostatic pressing of cemented carbide can eliminate the pores in the alloy and the drilling pool after sintering, and restrain the growth of WC grain. The Kennametal Inc installed the first heating chamber for 277mm * 1270mm in 1967. The temperature is up to 1500oC and the pressure can reach140MPa's hot isostatic pressing machine has taken the lead in successfully applying the technology of hot isostatic pressing to the production of cemented carbide. Since then, hot isostatic pressing technology has developed rapidly in foreign countries (especially in the United States).

Send your message to us

FeSi 72 For Making Ductile Cast iron

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords