External Wall Slabs and Floor Planks Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

External Wall Slabs and Floor Planks Making Machine

1. External Wall Slabs and Floor Planks Making Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of External Wall Slabs and Floor Planks Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

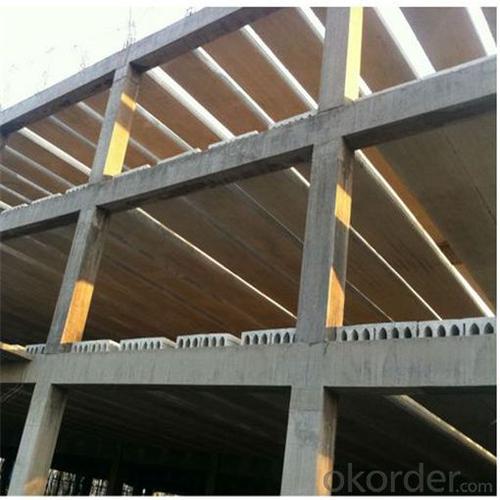

3. External Wall Slabs and Floor Planks Making Machine Images:

4. External Wall Slabs and Floor Planks Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Jan. 1 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost$62,000 on that date. It had a useful life of 10 years with no salvage value.June 30 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. Ithad a useful life of 5 years with no salvage value.The computer was sold for $14,000.Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost$39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.InstructionsJournalize all entries required on the above dates, including entries to update depreciation,where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assumedepreciation is up to date as of December 31, 2010.)

- You didn't state the year in which these transactions occurred. I'm assuming 2011. Jan. 1, 2011 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost $62,000 on that date. It had a useful life of 10 years with no salvage value. Annual depreciation = $62,000/10 = $$6,200 By December 31, 2010, the machinery would be fully depreciated. Dr Accumulated depreciation $62,000 Cr Machinery $62,000 June 30, 2011 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. It had a useful life of 5 years with no salvage value.The computer was sold for $14,000. Annual depreciation = $40,000/5 = $8,000 By December 31, 2010, the accumulated depr account would have a balance of $24,000 (3 yrs) You need to depreciate another 6 mths to June 30, 2011 Dr Depreciation expense $4,000 Cr Accumulated depreciation $4,000 after which the accum. depr. would be $28,000, and the carrying amount $12,000. If it was sold for $14,000, there would be a gain of $2,000 Dr Accum depr $28,000 Dr Cash $14,000 Cr Computer $40,000 Cr Gain on disposal of computer $2,000 Dec. 31, 2011 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value. Annual depr = ($39,000 - $3,000)/6 = $6,000 By December 31, 2010, the accum. depr. = $24,000 (4 yrs) You need to update depreciation by 1 yr Dr Depreciation $6,000 Cr Accum depr - Truck $6,000 after which the accum depr = $30,000, and the carrying amount = $9,000 Dr Accum depr $30,000 Dr Loss on scrapping of vehicle $9,000 Cr Vehicle $39,000

- Q: describe the ways in which bacterial machinery can be utilized to replicate mammalian genome?

- NONE NON-EXISTENT WON'T

- Q: can chimpanzees operate heavy machinery?

- I don't have direct experience but my answer to be definitely yes. Chimps are much stronger than human beings and very close to humans in DNA so they obviously can do some basic 'production line' type operations since they are less 'intelligent' than humans.

- Q: whre can i download this book?...Electric Machinery Fundamentals (Power & Energy)By Stephen J. Chapman-4th edi?

- I'm okorder /

- Q: I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q: Why might the machinery of war, set in motion by the assassination of Archduke Ferdinand, have been difficul?

- one major reason was the complex net of political and military alliances . the actual antagonists. Austria and Hungry drew in all of Europe Wilson and America wisely wanted to stay out the British tricked USA with the 'zimmerman telegram' and the sinking of the civilian ship the Lusitania, which was carrying forbidden military suppies ( ammunition) to Britain. About the same time a relevolution was taking place in Russia, communists were involved and the West was terrified of anything like communism. America actually sent troops to fight in Russia AFTER WW I.

- Q: Or do I have to claim my business as a medium size cooperation?

- mr. penis envy, my guess is you would have yourself an illegal medium size corporation . but that is ok, since you'll be illegal you don't have to pay taxes and the mexicans will have jobs so they can send money back to mexico to feed little mexicans. it's a win win situation! but seriously, just remember one thing though: immigrants, like the 45 illegal one's you mention, built this country so that your lazy *** can sit in front of a computer, call yourself 'penis envy' and ask moronic questions to kill time. thanks

- Q: On October 1, 2007, Machinery B was acquired with a down payment of $5,740 and the remainingpayments to be made in 11 annual installments of $6,000 each beginning October 1, 2007. Theprevailing interest rate was 8%. The following data were abstracted from present-value tables(rounded).Present value of $1.00 at 8% Present value of an ordinary annuity of $1.00 at 8%10 years .463 10 years 6.71011 years .429 11 years 7.13915 years .315 15 years 8.559

- $6,000 X 11 + $5,740

- Q: I have fat thighs but don't want to buy expensive machinery what do i do?

- run walk jumping jacks crunches push-ups with knees on the ground hop hop while sitting lift knees one by one duck walk

- Q: i want to buy from china

- through the service you just like engage a agent in China to help you to find what you need in China.

Send your message to us

External Wall Slabs and Floor Planks Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords