ETP for Metal Package of Industrial Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of ETP for Metal Package of Industrial Chemical Useage Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the ETP for Metal Package of Industrial Chemical Useage

Salient Features of DR Tinplate

The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths upto 550 +/-50 N/mm2, whereas single reduced material has strength less than 450 N/mm2 &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength upto 690 N/mm2 to the produced material.

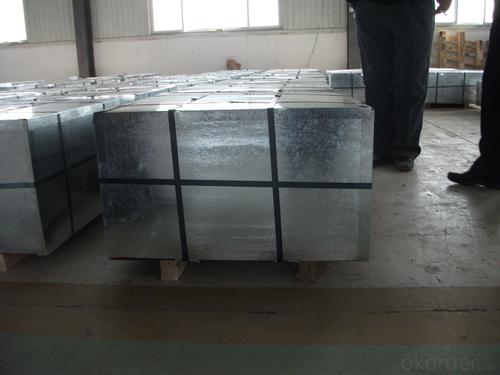

3.ETP for Metal Package of Industrial Chemical Useage Images

4.ETP for Metal Package of Industrial Chemical Useage Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of ETP for Metal Package of Industrial Chemical Useage

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: Can tinplate be used for packaging tobacco products?

- Yes, tinplate can be used for packaging tobacco products. Tinplate is a commonly used material for packaging due to its durability, resistance to corrosion, and ability to preserve the quality of the tobacco. It also provides a convenient and attractive packaging solution for consumers.

- Q: Can tinplate be used for bakery packaging?

- Yes, tinplate can be used for bakery packaging. Tinplate is a durable and versatile material that provides excellent protection for bakery products. It helps to maintain the freshness and quality of the baked goods by preventing moisture and oxygen from entering the packaging. Additionally, tinplate is also recyclable, making it an environmentally-friendly choice for bakery packaging.

- Q: How does tinplate affect the overall barrier properties of packaging?

- Tinplate enhances the overall barrier properties of packaging by providing a protective layer that effectively prevents the transfer of oxygen, moisture, and light. This barrier helps to preserve the quality, freshness, and shelf life of the packaged product, ensuring its integrity and safety.

- Q: How does tinplate perform in terms of light protection?

- Tinplate offers excellent light protection due to its opaque and reflective nature, effectively blocking out light and preventing its transmission through the material.

- Q: Can tinplate be used for solar panel applications?

- Yes, tinplate can be used for solar panel applications. Tinplate is often used as a protective coating for solar panels due to its corrosion resistance and ability to reflect sunlight. It acts as a barrier against moisture and environmental elements, ensuring the durability and longevity of the solar panels. Additionally, tinplate can enhance the overall efficiency of solar panels by reducing heat absorption and improving energy conversion.

- Q: How does tinplate packaging contribute to product protection during shipping?

- Tinplate packaging provides effective protection during shipping due to its durability and strength. It acts as a sturdy barrier against external elements, such as moisture, light, and air, which can potentially damage the product. Tinplate packaging also offers resistance to corrosion, ensuring the product's integrity throughout the shipping process. Its robust construction provides cushioning and prevents the product from being easily crushed or dented. Overall, tinplate packaging plays a crucial role in safeguarding the product from various risks, ensuring it reaches the destination in optimal condition.

- Q: Can tinplate be used for aerosol packaging?

- Yes, tinplate can be used for aerosol packaging. Tinplate is a common material choice for aerosol cans due to its strength, durability, and resistance to corrosion. It provides a protective barrier against moisture and oxygen, ensuring the integrity of the aerosol product. Additionally, tinplate can be easily formed into various shapes and sizes required for aerosol packaging.

- Q: How does the thickness of tinplate affect its strength and durability?

- The thickness of tinplate directly influences its strength and durability. Generally, thicker tinplate tends to be stronger and more durable compared to thinner tinplate. A thicker tinplate has a higher resistance to bending, denting, or puncturing, making it less prone to damage during handling, storage, or transportation. Additionally, the increased thickness provides better protection against corrosion and extends the tinplate's lifespan. However, thicker tinplate also tends to be heavier and more expensive. Therefore, finding the right balance between thickness and cost is crucial when considering the strength and durability requirements for a specific application.

- Q: How does the coating affect the properties of tinplate?

- The coating on tinplate significantly affects its properties. The coating provides a protective barrier against corrosion, enhancing the tinplate's durability and extending its shelf life. Additionally, the coating can improve the tinplate's resistance to chemical reactions and make it more suitable for food packaging applications. The coating also influences the tinplate's appearance, allowing for various decorative finishes. Overall, the coating plays a crucial role in enhancing the properties and performance of tinplate.

- Q: Can tinplate be used for ammunition?

- Yes, tinplate can be used for ammunition. It is commonly used for manufacturing shotgun shells and some types of bullet casings due to its durability and ability to withstand high pressures.

Send your message to us

ETP for Metal Package of Industrial Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords