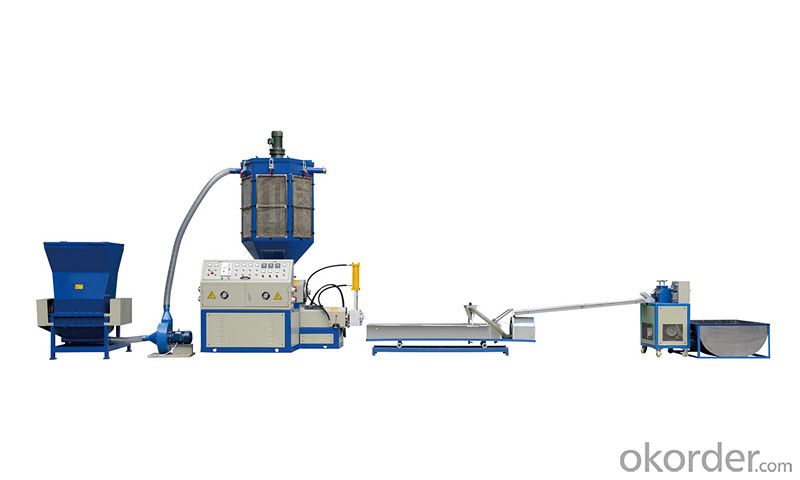

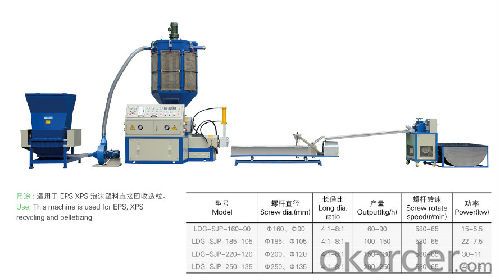

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Use of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

This machine is used for EPS ,XPS recycling and pelletizing, especially for sorting materials and transform rubbish into treasure. It is an ideal choice for environmental protection of the supermarket and the utility areas.

Features of EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

The machine adopt the fast compact , fast melting , extruding with filter , whole line design to recycling the material into the granules.The hole diameter of stamped sieve plate can be custom-made according the user's requirements.motor:15kw output:60-90kg/h

Packaging & Delivery

| Packaging Details: | Packed in wooden case,side screw force feeder pelletizing line |

|---|---|

| Delivery Detail: | Delivery Within 30-45 Working Days,side screw force feeder pelle |

Kindly feel free to contact with me if you need more detail informations.

And if convenience for you,welcome to visit our factory to know more about our machine.

- Q: For thin films such as polyethylene and polypropylene, what range of maximum absorption bands do you want to use laser cutting? Is there a laser for the corresponding band? What's the price?

- You should be electronic accessories, plastic die cutting class. Cutting these words with CO2 imported laser cutting machine, high precision, but also durable. Just use a mask when you cut. See how high your accuracy is. Let's start at about one hundred thousand.. At present, this kind of used for a long time, everyone should use is the laser master this.

- Q: Figure plastic parts, motorcycle, instrument shell, plasticI want to refit the instrument and refit the instrument and meter. The shape of the instrument shell is identical. The space between the instrument shells is too emptyWhich tools cut material thickness about 3mm?Art knife, scissors line, art knife, control power, easy to scratch, scratches, scissors left section is too rough

- Pre painted wire shape curve or sandpaper polished OK wire saw a fileHeating line 3 mm, too thick electric iron difficult to burn, and cut plastic, less electric iron can melt plastic, can remove plastic; two heating edge treatment is not troublesome, only plastic edge heating embrittlement, and even crack melting, slag hanging difficult to smoothAngle grinder into space maneuvers each position angle grinder wrong to manmanmo to prevent brittle plastic heating melting plastic plug wheel

- Q: The principle of elastic dynamic car foam cutting machine principle and the principle of small electric fan

- , the rubber band can be converted into mechanical energy.

- Q: Can plastic products be cut by laser?

- if more than 50%, that can be quite dangerous, it is easy to cause cancer! Time is usually around 3 years!

- Q: Cut PVC plastic, what saw blade?

- Should be able to use large right aluminum alloy saw blade 405x2.8x25.4x160THow much do the specific size, you can ask the Chi Xinhang tool can cut effective solution for Aluminum Alloy saw blade grinding machine at.

- Q: There are no large tools available, and the cutting surface requires no burrs!! Thank you.

- Electric cutting method, with a thinner than the hair of a thin copper wire, looking for a cork bar, made into bow, copper wire when the string. Look for two dry cells connected in series at both ends of the copper wire. The copper wire will burn. If the temperature is not enough, continue to add batteries.

- Q: Structure features of foam cutting machine

- Hengxiang CNC foam cutting machine automatic control system consists of CNC, PLC, NC card, industrial computer and servo system, through the company's development in accordance with the special requirements of the process automation control software of thermal cutting, automatic programming (the workpiece does not need to input complex and cumbersome code, just by drawing on CAD input. Processing of complex shape or pattern). The system can control the flame cutting head running 3D coordinates (X, Y, Z three axis servo motor drive system composed of concrete actions, is under the control of a computer program, X-Y axis servo motor drive flame cutting head in accordance with the procedures specified in advance the trajectory of walking, resulting in the workpiece plane cutting to meet the requirements of the shape. But in the process of cutting walking, if the workpiece surface roughness, Z axis servo motor can control the cutting head up and down, to adjust the flame between the nozzle and the workpiece surface distance, keep constant, so as to achieve the best effect of cutting.

- Q: To make a plastic cutting machine. The main is the removal of 2 10CM around the rim. Plastic (PPS material), with what method good., scissors. Laser cutting. After heating the cylinder sealing knife under the action thought. But hope master guiding is not ideal!

- Water jet cutting, because mechanical cutting should take into account the chip, hot cutting and softening

- Q: How to use plastic cutters to seal cartons?

- With the blower's hot air blowing on the tape, it seems to be a lot easier, but the premise is that your belt quality can not be very good, and the other is that the quality of the surface of the carton should be good enough, if there are wrinkles, what is not estimated ~ ~!

- Q: Cutting circular tube clamp Ciqieduogen tube.

- It's up to you what is the specific way of cutting, cutting tools and what specific pipe specifications will influence the cutting quantity and speed,

Send your message to us

EPS Foam Recycling And Pelletizing Line LDG-SJP-160-90

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords