EPDM Membrane Vulcanization 2.OOMM for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

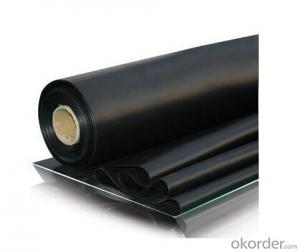

EPDM Membrane Vulcanization 2.00mmfor Waterproof System

Description Of EPDM Membrane Vulcanization2.00 mm:

1. EPDM 2.00 mm membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM 2.00 mm membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Main Features of EPDM Vulcanization EPDM Membrane2.00 mm:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. UV resistance

Applications of EPDM Rubber Waterproof Membrane2.00 mm:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

IMages of EPDM Vulcanization Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be painted over?

- Indeed, painting over a waterproofing membrane is possible. Nevertheless, it is crucial to guarantee the cleanliness, dryness, and absence of any debris or loose substances on the membrane prior to applying paint. Furthermore, it is advised to employ a paint specifically formulated for waterproofing membranes in order to achieve proper adhesion and durability. It is equally essential to adhere to the manufacturer's guidelines for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Yes, a waterproofing membrane can be used on tunnels with subway systems. In fact, it is highly recommended to install a waterproofing membrane in subway tunnels to prevent water infiltration and potential damage to the structure and electrical systems. The waterproofing membrane acts as a barrier to keep water out and protect the tunnel from moisture-related issues such as corrosion, mold, and deterioration. It is important to choose a waterproofing membrane that is specifically designed for tunnel applications and can withstand the unique conditions and challenges of subway systems, such as high traffic loads, vibrations, and exposure to chemicals. Additionally, the installation of the waterproofing membrane should be done by experienced professionals following the appropriate guidelines and specifications to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- Yes, a waterproofing membrane can be used on modified bitumen roofs. In fact, it is a common practice to enhance the waterproofing capabilities of modified bitumen roofs by applying a separate waterproofing membrane on top. This additional layer provides an extra barrier against water infiltration and helps prolong the lifespan of the roof.

- Q: How does a waterproofing membrane adhere to the surface?

- A combination of mechanical and chemical bonding is responsible for the adherence of a waterproofing membrane to a surface. Typically, a specialized adhesive or primer is used to apply the membrane, aiding in the creation of a robust bond between the membrane and the surface. Mechanical bonding occurs when the adhesive or primer penetrates the surface's pores, establishing a physical bond between the membrane and the substrate. This guarantees a secure attachment, enabling the membrane to withstand various forces. Chemical bonding is also crucial in the adhesion process. The adhesive or primer contains chemicals that react with the surface, resulting in chemical bonds with the membrane. This chemical reaction produces a durable and long-lasting bond capable of withstanding environmental factors like temperature changes, moisture, and UV exposure. Moreover, the composition of the waterproofing membrane itself contributes to its adhesion. Many membranes are made of materials with inherent adhesive properties, such as bitumen or rubberized asphalt. These materials possess natural tackiness, allowing them to adhere to the surface without the need for additional adhesives or primers. In summary, the adherence of a waterproofing membrane to a surface relies on a combination of mechanical and chemical bonding facilitated by specialized adhesives or primers. This ensures a strong and durable bond, effectively safeguarding the surface against water damage.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. The membrane serves as a protective layer that prevents water from seeping into the underlying structure, ensuring that the rooftop garden remains dry and well-maintained.

- Q: What is the cost of installing a waterproofing membrane?

- The installation expense of a waterproofing membrane can fluctuate based on several factors, including the dimensions of the area to be waterproofed, the type of membrane employed, and the intricacy of the installation procedure. Typically, the cost per square foot can vary between $3 and $10. Nevertheless, it is crucial to bear in mind that this is merely a ballpark figure, and the real cost may be higher or lower depending on the particular demands of the project. It is advisable to seek guidance from an expert waterproofing contractor to obtain a precise cost estimate customized to your specific requirements.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Using a waterproofing membrane comes with its fair share of drawbacks and limitations. One issue is the time-consuming and labor-intensive installation process. These membranes require careful surface preparation and multiple layers, which can be both time-consuming and require skilled labor. As a result, the overall cost of the project may increase. Another limitation is that not all surfaces are suitable for waterproofing membranes. Certain membranes are designed for specific types of substrates, such as concrete or metal, and may not adhere properly to other materials. To ensure proper adhesion and effectiveness, it is crucial to select the appropriate type of membrane for the specific surface. Moreover, waterproofing membranes can be sensitive to environmental conditions. Exposure to extreme temperature fluctuations, UV rays, and chemicals can degrade the membrane over time, reducing its effectiveness. To ensure the longevity of the membrane, regular inspections and maintenance may be necessary. Furthermore, during installation or due to external factors such as foot traffic or heavy objects, waterproofing membranes can be susceptible to damage. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, in certain situations, waterproofing membranes may not completely prevent water penetration. If there are existing cracks or structural issues in the substrate, water may find a way to seep through, bypassing the membrane. Therefore, it is important to address any underlying structural issues before applying the membrane to ensure optimal performance. In conclusion, while waterproofing membranes offer significant benefits in terms of water damage protection, it is crucial to consider these limitations and drawbacks before deciding to use them in specific applications.

- Q: What is BSB waterproofing membrane

- Scope of application: 1. Polyester Felt-based elastomer modified asphalt waterproofing membrane for industrial and civil construction of the roof and underground waterproofing works. 2. Glass fiber reinforced polyester mattress base coil is suitable for mechanical fixed single layer waterproof, but through the wind load test. 3. Fiberglass mattresses are suitable for structural roofs and underground waterproofing works; 4. Exposure to the use of the upper surface of the insulating material for the opaque mineral pellets of the waterproofing membrane. 5. Underground engineering waterproofing should be used surface insulation material for the fine sand of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on tunnels with ventilation systems?

- Yes, a waterproofing membrane can be used on tunnels with ventilation systems. In fact, it is commonly used to prevent water infiltration and protect the structure of the tunnel. The membrane is installed on the exterior walls and ceiling of the tunnel, ensuring that any water that may enter is diverted away from the tunnel and its ventilation system. This helps to maintain the integrity of the tunnel and ensures proper functioning of the ventilation system.

- Q: Can a waterproofing membrane be used in temporary or temporary structures?

- Yes, a waterproofing membrane can be used in temporary or temporary structures. It provides an effective barrier against moisture, protecting the structure from potential water damage during its temporary lifespan.

Send your message to us

EPDM Membrane Vulcanization 2.OOMM for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords