Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Description

Also known as chromed steel, tin-free steel (TFS) is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.

The product complies with ASTM A-657 Specification and is manufactured with low current density (TFS-III) and is supplied in coils (up to 12 metric tons)or sheets.

2.Main Features of the Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

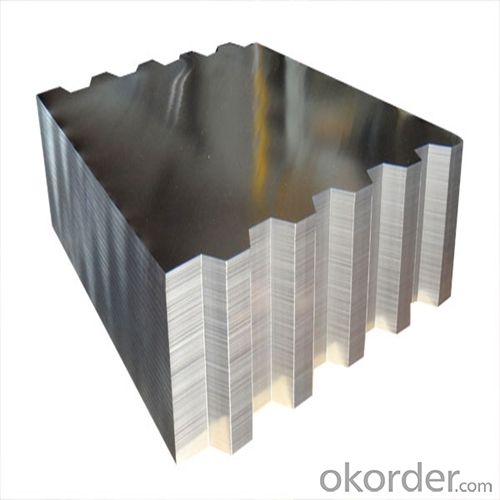

3.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Images

4.Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the common surface finishes for tinplate?

- The common surface finishes for tinplate include bright, stone, and matte finishes.

- Q: What is the tensile strength of tinplate?

- The tensile strength of tinplate typically ranges from 180 to 220 megapascals (MPa).

- Q: How does tinplate contribute to the protection of musical instruments?

- Tinplate contributes to the protection of musical instruments by providing a durable and corrosion-resistant coating, which helps prevent rust and damage caused by moisture and environmental factors. Additionally, tinplate can be used in the manufacturing of instrument cases, offering a lightweight yet strong material that safeguards instruments during transportation and storage.

- Q: What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include ensuring proper lifting and transportation techniques to avoid damage, managing the weight and size of the coils for safe handling, maintaining cleanliness to prevent contamination, and implementing efficient storage and inventory management systems. Additionally, coordinating with suppliers and customers to ensure timely delivery and minimizing transit damage are also significant challenges.

- Q: Can tinplate be used for high-pressure containers?

- No, tinplate is not suitable for high-pressure containers as it is not strong enough to withstand the pressure.

- Q: How does tinplate packaging contribute to product visibility?

- Tinplate packaging contributes to product visibility through its glossy and reflective surface, allowing consumers to easily spot and identify the product on shelves. Additionally, tinplate packaging can be customized with vibrant colors and eye-catching designs, further enhancing the visibility and attractiveness of the product.

- Q: How does tinplate contribute to the shelf life of canned products?

- Tinplate contributes to the shelf life of canned products through its ability to prevent corrosion and maintain product quality. The tin coating on the steel substrate acts as a barrier, protecting the can from rusting and preventing any reaction between the metal and the food inside. This helps to maintain the integrity of the can, ensuring that it doesn't leak or become contaminated. As a result, tinplate cans can effectively preserve the freshness, taste, and nutritional value of the canned products, extending their shelf life significantly.

- Q: Can tinplate be used for packaging products with specific storage requirements?

- Yes, tinplate can be used for packaging products with specific storage requirements. Tinplate is a durable and corrosion-resistant material that provides excellent protection for products from light, moisture, and oxygen. It can maintain the quality and freshness of the stored items, making it suitable for packaging products with specific storage requirements such as food, beverages, and chemicals.

- Q: Can tinplate be used for musical instruments?

- Yes, tinplate can be used for musical instruments. Tinplate is often used in the construction of various musical instruments, such as harmonicas or tambourines, due to its durability, flexibility, and ability to produce unique sounds.

- Q: Can tinplate be recycled with other metals?

- Yes, tinplate can be recycled with other metals. Tinplate is typically made from steel coated with a thin layer of tin, and both steel and tin can be recycled. When tinplate is recycled, it is usually separated from other materials and processed separately to recover the steel and tin content.

Send your message to us

Electrolytic Tinplate and TFS for Metal Containers Use 0.26mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords