EANTE sealing up srew arbor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Haiyuan New Material possesses china’s first fully automatic long fiber reinforced thermoplastic composite mould pressing production line with independent intellectual property, referred to as LFT-D line.

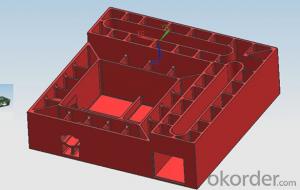

Why we developed EANTE formwork?

Superiority:

General worker can assemble and remove easily, save more labor cost.

The reinforcing ribs of EANTE formwork can be used to instead of the steel tube and wood.

Preassemble the EANTE formwork in the factory and fix it in the construction location.

The size accuracy of the composite formwork is better than that of the steel formwork and the wooden formwork. The concrete surface cast by EANTE Formwork is quite smooth, without any flaw, and no release agent is applied to assist the formwork removing.

We developed our own software with the characteristics as follow:

a. Computation time: it depends on the complexity of the architecture drawing;

b. Construction drawing: it is shifted from assembling drawing easily;

c. Material list: the assembling designing software would generate a list of formwork elements and auxiliary products.

Enviromental: EANTE Formwork is made from composite material, which is low-carbon, recyclable and environment-friendly.

Saftness: The labor, large equipment, electric saws and iron nails are used much less on the building site, which leads to simplified on-site management and the safer construction.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: Why the floor is not plastic building materials square wood and template

- Must be strong and durable, the environment is bad, need to find strong

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- This does exist. The reason is that the plastic building template in the cut and fixed convenience, significantly weaker than the wooden building template, and in the demolition process, due to the brittleness of plastic, but also easy to break, and the cost of plastic template is too high, so the site Are generally willing to use wooden building templates. If you want to improve the number of wood construction template use, that is, cost, it is recommended that you choose building templates within 30 strong business

- Q: Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

Send your message to us

EANTE sealing up srew arbor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords