Ductile or Cast Iron Manhole Cover of Standard Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 3500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service

life (at least 30 years). The quality meets the same kinds cast ion manhole covers but

the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

Packaging & Shipping:

Packaging: Details Pallet with bubble film, Carton or with pallet.

Delivery Detail: 8 days if your order is 20"container.

Specification:

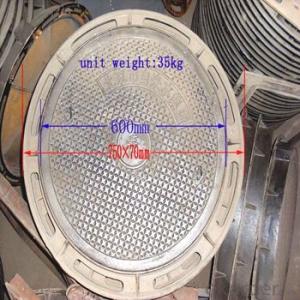

| No. | Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Size(mm) | Unit Weight (kg/set) |

| 1 | PCE300 | C250 | 200×200 | 300×300 | 35 | 8 |

| 2 | PCE400 | C250 | 300×300 | 400×400 | 40 | 22 |

| 3 | PCE500 | C250 | 400×400 | 500×500 | 45 | 26 |

| 4 | PCE550 | C250 | 500×500 | 550×550 | 45 | 30 |

Our Services:

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.

Meanwhile, a number of experienced workers do the strictly Quality control and have

production tracking program.

5. Our price: we are the factory,

we provide the most competitive price with good quality, and

large order quantity will get big support by us!

6. Professional technical support with free charge.

Pictures:

FAQ:

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building

materials you buy from Miami, Dubai ,Italy, South Africa or your local market are

imported from China. So why not buy direct from China. The key point is to find a

reliable supplier who is honest and professional to take care of the quality and

delivery time.

3.Chinahas full range of Manhole covers which Follow En124 for your market, like

A15,B125,C250,D400.

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to the grade of the parts, according to the relevant standards, the regular drawings will be noted in the technical requirements of the parts.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

Send your message to us

Ductile or Cast Iron Manhole Cover of Standard Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 3500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords