Ductile Iron Round Manhole Cover from Chinese Foundry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Material: Cast(Grey) Iron (GG 20, GG 25) and Ductile(SG) Iron(GGG 50).

Sizes: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening.

Load Rating: A15, B125, C250, D400, E600 and F900

Painting: Black Bitumen, Epoxy and other paint as per provided by customers.

Other Features: Hinging, Locking provision available, Leak proof and customized designed available.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

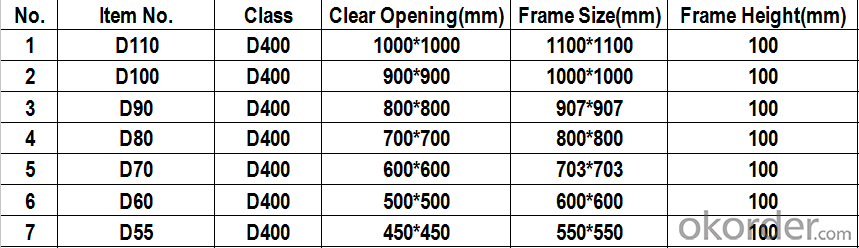

Specifications

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Even distribution is a good thing. Generally, the machining allowance of the casting is uneven.If the processing depends on how your processing techniques have been arranged.In the NC milling plane contour machining, when the rough margin is large, how to deal with.1. Return to the foundry, too large margin improvement.2. Then you can spend more time on it.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Ductile Iron Round Manhole Cover from Chinese Foundry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords