DUCTILE IRON PIPES AND PIPE FITTINGS K9 CLASS DN80

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material : Ductile Cast Iron

Size Range : DN 80mm to DN 2000mm

Unit Effective Length : 6m or 5.7m

Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

Annual capacity : 200,000 tons

Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

Special requirements on external coating and internal lining can be applied

We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Additional Parts:

Each pipe is strictly inspected according to related standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering you a competitive price.

A copy of original inspection reports of pipes will be offered after shipment.

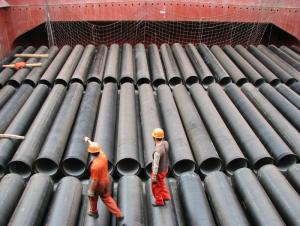

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis.

- Q: Can ductile iron pipes be used for water distribution networks in rural areas?

- Yes, ductile iron pipes can be used for water distribution networks in rural areas. Ductile iron pipes have excellent strength and durability, making them suitable for various applications, including water distribution. They can withstand high pressure, provide a long service life, and have good resistance to corrosion and external stresses. Additionally, ductile iron pipes are relatively cost-effective and require minimal maintenance, making them a reliable choice for water distribution networks in rural areas.

- Q: What material is the cutting tool for ductile iron?

- They are all hard alloy materials, all of which are CVD coatings, but the products produced by different manufacturers will be very different.

- Q: How do ductile iron pipes handle water hammer in high-rise buildings?

- Known for their durability and strength, ductile iron pipes are an excellent option for managing water hammer in high-rise structures. Water hammer, a common occurrence when water flow abruptly halts or changes direction in pipes, causes pressure surges that can strain and potentially harm the pipes. Engineered to withstand high-pressure scenarios, ductile iron pipes exhibit remarkable resistance to water hammer. With their high tensile strength, these pipes can endure sudden pressure changes without warping or fracturing. This feature is especially crucial in high-rise constructions where water distribution must accommodate various floor pressures. Furthermore, the outstanding corrosion resistance of ductile iron pipes bolsters their ability to handle water hammer. Over time, corrosion weakens pipes, making them more prone to failure during pressure surges. However, the corrosion resistance of ductile iron pipes guarantees their structural integrity even in high-pressure circumstances. Moreover, the flexibility of ductile iron pipes enables them to absorb and dissipate the energy generated by water hammer. Consequently, the overall system experiences minimal impact, reducing the potential for damage. Absorbing energy also contributes to minimizing noise and vibrations associated with water hammer, thus enhancing the efficiency and comfort of the water supply system. To summarize, ductile iron pipes are well-suited to manage water hammer in high-rise buildings. Their strength, corrosion resistance, and flexibility make them a reliable choice for delivering water under varying pressures while upholding the system's integrity.

- Q: Can ductile iron pipe be used for mining applications?

- Yes, ductile iron pipe can certainly be used for mining applications. Ductile iron is a type of cast iron that exhibits significant tensile strength, flexibility, and durability, making it suitable for demanding and rugged environments like mining. Its high strength-to-weight ratio allows for easy handling and installation, making it a cost-effective choice for mining operations. Ductile iron pipes are resistant to corrosion and have excellent mechanical properties, including high impact and fatigue resistance. These properties make them ideal for transporting various materials commonly found in mining, such as water, slurries, and abrasive ores. Additionally, ductile iron pipes have a long lifespan, ensuring reliable performance and minimal maintenance requirements in mining operations. Furthermore, ductile iron pipes can withstand high pressures and maintain their integrity under extreme conditions, making them suitable for underground mining applications. They can handle the demanding requirements of deep mining operations, including the transport of water for cooling or dust suppression, as well as the drainage of wastewater or mine dewatering. Overall, ductile iron pipes provide the necessary strength, resilience, and corrosion resistance required for mining applications. Their versatility, durability, and ease of installation make them a valuable choice for mining operations, ensuring efficient and reliable material transport while minimizing downtime and maintenance costs.

- Q: Are ductile iron pipes suitable for use in irrigation pivot systems?

- Yes, ductile iron pipes are suitable for use in irrigation pivot systems. They are known for their durability, strength, and resistance to corrosion, making them a reliable choice for transporting water in agricultural applications. Additionally, ductile iron pipes have a high tolerance for pressure and can withstand the stresses caused by irrigation pivot systems.

- Q: Can ductile iron pipes be used for pressure reducing stations?

- Ductile iron pipes are indeed capable of being utilized in pressure reducing stations. Renowned for their robustness and resilience, these pipes are well-suited for managing applications involving high pressure. Their exceptional resistance to corrosion allows them to endure the mechanical pressures and strains typically associated with pressure reducing stations. Moreover, the smooth interior surface of ductile iron pipes minimizes friction losses and contributes to maintaining a consistent and regulated pressure within the system. Consequently, it can be concluded that ductile iron pipes are a dependable and frequently employed material in pressure reducing stations.

- Q: Can ductile iron pipes be used in contaminated groundwater systems?

- Yes, ductile iron pipes can be used in contaminated groundwater systems. Ductile iron pipes are known for their corrosion resistance, making them suitable for handling water with various levels of contamination. Additionally, their strength and durability allow them to withstand the harsh conditions of contaminated groundwater systems.

- Q: What is the K9 standard pressure for ductile iron pipes?

- The annealed ductile iron pipe is composed of ferrite and pearlite. The mechanical properties of the ductile iron pipe are better. Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc.. Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external pressure bearing better tightness and corrosion resistance; from the point of view, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: What is the expected roughness coefficient of ductile iron pipes?

- The roughness coefficient of ductile iron pipes can differ based on different factors like pipe diameter, age, and condition, resulting in variations. However, typically, the roughness coefficient for ductile iron pipes falls within the range of 0.01-0.015 mm. This value signifies the average roughness of the pipe's internal surface and plays a crucial role in hydraulic calculations for establishing the flow characteristics and pressure losses within the pipe network. It is worth mentioning that these values are approximate and subject to change depending on specific pipe conditions and applications.

- Q: Do ductile iron pipes require special maintenance?

- Indeed, special maintenance is necessary for ductile iron pipes. Despite their reputation for being strong and durable, ductile iron pipes are still vulnerable to specific types of corrosion. To prevent corrosion and extend the pipes' lifespan, regular maintenance is crucial. This maintenance typically involves conducting periodic inspections to identify any signs of corrosion or damage, as well as implementing cleaning and protective coating procedures. Furthermore, it is important to handle and install the pipes correctly to maintain their integrity. By regularly maintaining the pipes and adhering to industry best practices, one can prevent leaks, breaks, and other issues, ultimately saving valuable time and money in the long term.

Send your message to us

DUCTILE IRON PIPES AND PIPE FITTINGS K9 CLASS DN80

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords