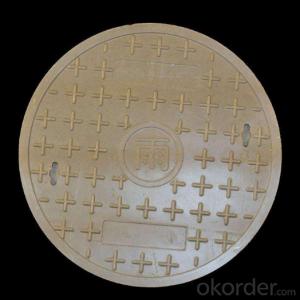

Ductile Iron Manhole Covers With EN124 Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Sample is available for free.

2. Free charge of design labels and cartons.

3. Professional technical support with free charge.

4.Packing

Steel or wood pallet, or as per customers' requirements'

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| D90 | D400 | 800*800 | 907*907 |

Materail:ductile iron,Gray cast iron

Tested item standad

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4

Water-absorption<1.0

Surface treatment

Black bitumen coated and hot gavanized

Smooth surface and anti-theft

Advantages

Good compressive, water-proof, hot sale around the world,anti-corrosion, serviceable life (at least 30 years).

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products in China, Our prices are very favorable and competitive. The customers from all-over the world.

2.How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.How about your service?

We provide packaging service and after sale service as well.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Steel parts are not familiar. But after spraying, the powder should be divorced from the adhesive force is too low, try to provide the surface roughness of the casting

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: Cause of choking of casting parts

- Choke fire is the process of pouring a large number of gases can not be discharged smoothly, boiling in the metal liquid, resulting in a large number of castings in the pores, and even incomplete casting defects

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: What are the general technical requirements for casting parts?

- Satisfy appearance quality (appearance defect, quality change, size deviation)Intrinsic quality (composition, properties, internal organization)Service performance (abrasion resistance, corrosion resistance, heat resistance, pressure resistance)

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

Send your message to us

Ductile Iron Manhole Covers With EN124 Made by Professional Manufacturers in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches