Ductile Iron Manhole Cover with Different Specifications

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

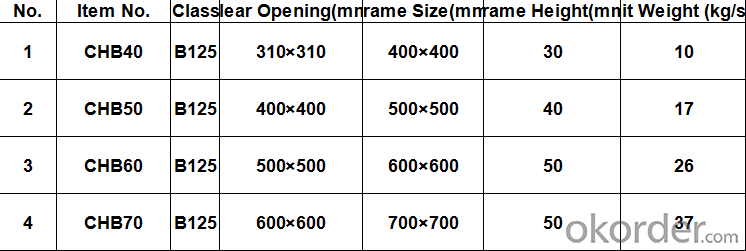

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

15.Size: Customer's Request

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Package

Q: Can I change your package Way?

A: Yes, we can make the form of the package and transportation according to your request, but if any additional charge occurs, you have to pay for it.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

Send your message to us

Ductile Iron Manhole Cover with Different Specifications

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords