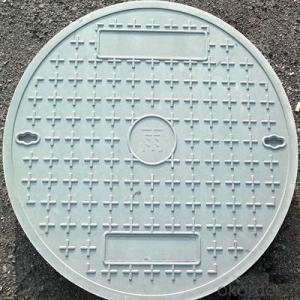

Ductile Iron Manhole Cover with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or samples.

2) Color: black, Grey, green, blue and Marble , etc.

3) Applications: water supply and drainage, fire engineering, natural

4) Inspection: in-house or the third party as per customer's request.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| CHB50 | B125 | 400×400 | 500×500 | 40 | 17 |

| CHB60 | B125 | 500×500 | 600×600 | 50 | 26 |

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal

and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press. Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

3. Could you specially design and produce for clients?

A: Of course, we have all kinds of professional engineers. We can design and produce special products according to customers' requirements. Such as: special size, special control, OEM, etc.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

Send your message to us

Ductile Iron Manhole Cover with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches