Ductile iron manhole cover telecom manhole cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description: |

Manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthoriz

-ed persons and material.

We produce various classes of manhole cover and gratings in gray iron or ductile iron from Class A15

to F900 according to customer's sample or requirm

-ent.

Material | Ductile iron |

Surface Treatment | Painting |

Load | 15 125 250 400 600 900 |

Standard | EN124-2015 EN1433 |

Feature | Easy to install noise reduction |

1. High load strength

Less noise and lower vibration transmissions.

2. Against theft,noise and rust.

3. Durable life.

4. Free design

Class A15 Area which can only be used by pedestrians and pedal cyclists

Class B125 Folkways, pedestrian areas and comparable areas, car parks or parking decks

Class C250 For gratings installed in the area of kerbside channels of roads which, when measured from the Serb edge, extend maximum 0.5 m into the carriageway and maximum 0.2 m into the foot way

Class D400 Arrive ways of roads (pedestrian streets included), hard shoulders and parking areas for all types of road vehicles.

Class E600 Areas subject to high axle loads such as docks and airports

Class F900 Areas subject to very high axle loads such as airports

| Item | Waterproof square 60x60 ductile iron manhole cover |

| Brand name | Better United Casting |

| Size | 200mm-1000mm |

| Type: | Round,square |

| Material | Gray Iron, Ductile Iron, Malleable iron |

| Coating | Cold applied black bitumen Antirust oil, Plating, Paint, Powder Coating, epoxy coating or as per customers' requirement. |

| Application | Municipal construction |

| Loading pressure | EN124 A15,B125,C250,D400,E600,F900, or as per customers' drawings or samples. |

| Advantages | Anti-noise ,Anti-theft,anti-rust,long life service. |

| Package | Pallet and wooden case,or as per customers’ requirements |

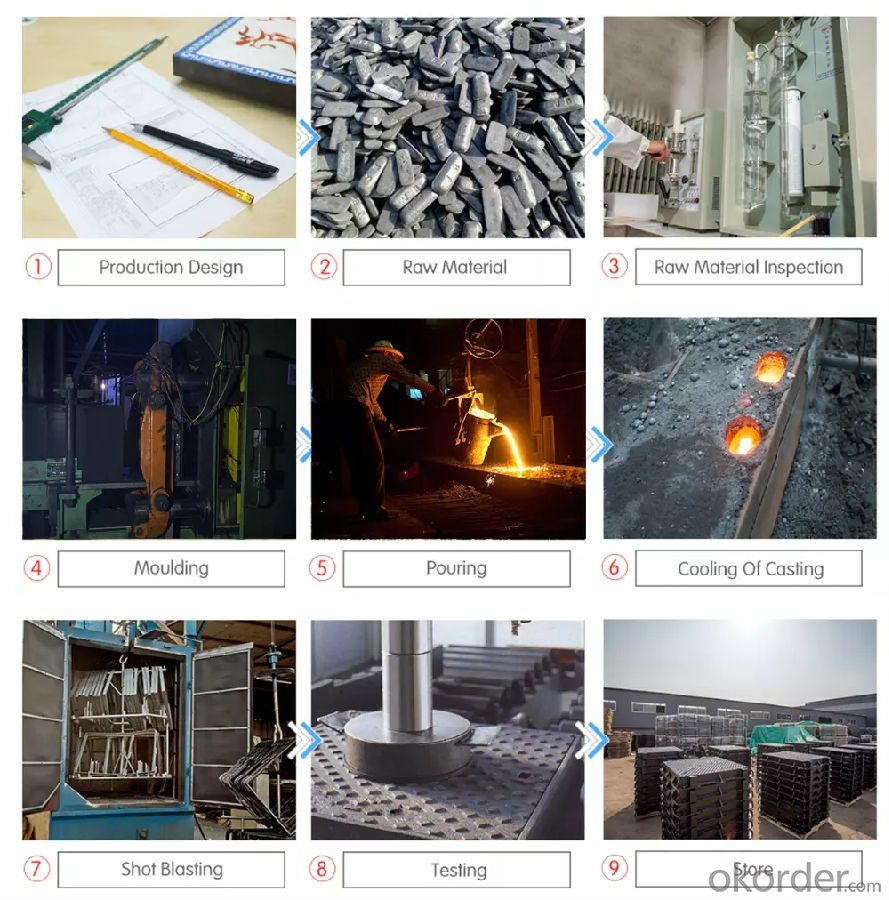

Production Flow:

Packing & Delivery

Packing Details:Plywood pallet; steel pallet; as per custom request

Delivery Time:Different amount of time will be required for different

Fastlead time: Tooling capability 7days ; Sample making 7days

Our Service:

We produce various classes of manhole cover and gratings in gray iron or ductile iron from Class A15 to F900 according to customer's sample or requirments.

OEM&ODM service.

We can design the new 2D or 3D drafts in 2 hours.

All kinds and specifications of equipment, strong production capacity, whether it is manual or mechanical modeling, whether horizontal or vertical lines, regardless of size, demand, we can all meet.

Fast lead time: one week for the mold, one week for the sample, one month for the delivery, time-saving and super valued is our ultimate goal.

Quality System.

With global valued customers.

- Q: What are the casting parts used to test shrinkage holes?

- 3 fluorescent magnetic powder, this method can also be found in part.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- As a pig iron smelting, iron smelting belongs to physical, two belongs to the chemical refining, smelting, smelting generally not as a product after use, the product can be used as a chemical composition and casting the two refining, in general is to scrap as additional material after melting making products; engine castings have professional manufacturers making castings. You can own professional production of engine castings.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- There are several casesThe first hole with a diameter of less than 4MM is generally not done, or as a hole location only for a period of less than 10MM.Second for the big hole, some of the reasons for the holding force, we must increase the slope, direct tapping is unlikely, so it still needs post-processingThird for products with high tightness requirements, some cores need to be made even if they are very small, so they can be tapped directlyFourth, some due to technical requirements, regardless of the size of each other's requirements must be made, there is no wayThe above methods are common, and they will encounter many small problems in actual production.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Valve sand core mold drying is not in place, excessive water content

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

Send your message to us

Ductile iron manhole cover telecom manhole cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords