Ductile Iron Manhole Cover C250 for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1.Advantages:

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

2.Applications:

water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

3.Designs:

based on EN124 standard and according to customer's drawing or samples.

4.Color:

black, Grey, green, blue and Marble , etc.

5.Inspection:

in-house or the third party as per customer's request.

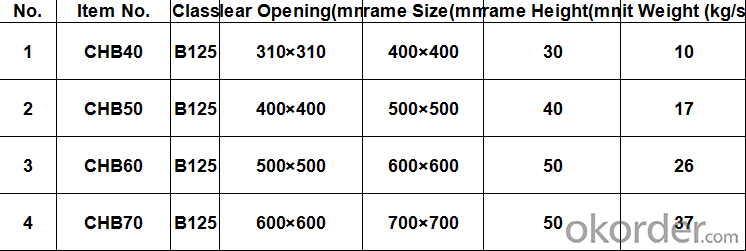

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Package

Q: Can I change your package Way?

A: Yes, we can make the form of the package and transportation according to your request, but if any additional charge occurs, you have to pay for it.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguishing between forging and casting can be done from the following points:From the principle of distinguishingForging processing of machining by hammer or press and other equipment for forging parts produced in hot state, casting processing of metals into liquid, pouring into the cavity with a specific shape, produced by machining parts after cooling solidification. Simply say that forging is the metal soft pinch molding, and casting the metal into thin cooling solidification.

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

Send your message to us

Ductile Iron Manhole Cover C250 for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches