Ductile Iron Manhole Cover C250 and D400 for Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features:

1) Production information

manhole cover are manufactured for construction and public use .Manhole cover shall be smooth and free sand holes , blow holes , distortion or any other defects

2) Material

a) Ductile iron GGG500&400-12

B) Grey iron GG20

3) Designs

a) EN124 Class B125 C250 D400 ,with different size and grammage, or as per customers requirement

b) Major standards designs available

c) as per customers' drawing or samples

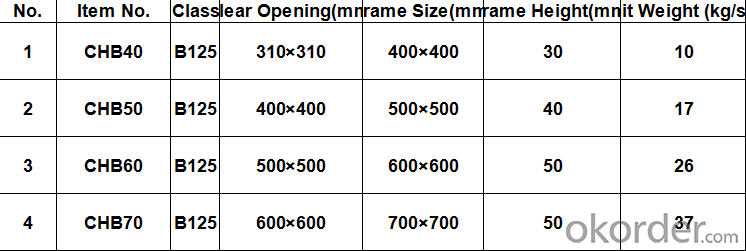

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging and Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

Send your message to us

Ductile Iron Manhole Cover C250 and D400 for Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches