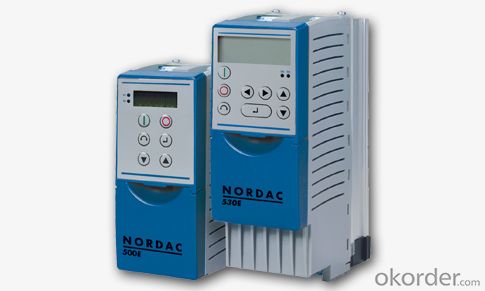

drive electronics SK 500E - Modular frequency inverter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SK 500E - Modular frequency inverter

Following its introduction in the market the SK 500E product series has become successfully established and now the power range has been extended to 90kW. This extends the success factors of these components to a wider field of applications.

Modular compact inverter: SK 500E

With the SK 500E series of frequency inverters, Getriebebau NORD offers intelligent and costeffective drive solutions with scaleable equipment options, which are all fully compatible with regard to motor performance range, supply voltage and sizes. The basis for all models is a well-equipped basic unit with expansion possibilities through optional modules. SK 500E inverters are suitable for all application areas and can be easily adapted to specific requirements with plug-in technology units.

Performance grading:

The SK 500E product series offers a wide range of features which are necessary for application-specific drive solutions. Through different configuration levels, these can be used "in the same box". The inverters include the following functions, which are state-of-the-art for industrial applications.

"Safe stop" (STO) as per EN ISO 13849-1 Cat.4,

Performance level e EN 61508 SIL3CANopen interface on board

Incremental encoder input (TTL) on board

Absolute encoder via CANopen, SSi, BiSS, Hiperface, EnDat

POSICON positioning control

External 24V power supply for control board

Synchronous motor operation (PMSM)

PLC logic function

Sizes 1 - 4 (0.25 - 7.5 kW):

Frequency inverter SK 500E with integrated mains unit / SK 505E with external 24V supply

SK 500E / SK 505E basic equipment:

Sensorless current vector control (ISD control)

Line filter Class C2, Class C1 up to 5 m

Brake management, electro-mechanical motor brakes

Brake chopper for braking resistor

RS 232 PC diagnostic interface

4 switchable parameter sets

All normal drive functions

Automatic flux optimisation (energy saving function).

Process controller / PID controller

Consistent parameter structure

Simple to operate

All common field bus systems

Factory setting for parameters for standard applications

Scalable display values

High quality regulation and short reaction times

- Q: Step into the motor drive red light for the cause of the failure

- Rezai MA860H stepper motor drives, ac and dc all can use power supply, with super wide voltage range, shall not exceed 90 v voltage is highest, the lowest not less than 24 v, Suggestions for 28-80 - v voltage range; It can be used in the 57, 85, 86 series and 110 series. There are 16 types of microsteps, the maximum number of steps is 51200Pulse/rev. The current range is 2.4 to 7.2 A, with A current of 8 and A current of 0.6 A. Automatic half flow, overpressure, over-current protection. The resai MA860H step motor drive has two red and green lights. The green light is a power indicator, and the green light is always bright when the driver is on.

- Q: I'm now turning the drive down to 6400 Means I send a pulse to stepper motor drives It divided it into 6400 pulses to the stepper motor or I send 6400 pulses to stepper motor drives It sends a to stepper motor?

- Both of the master's understandings are completely wrong! 6400 means that the controller (controller refers to the movement control CARDS, PLC, CNC system and other device can send pulse) after sending 6400 pulse, the motor can turn a week. This will adjust the system's accuracy and improve the stability of the motor.

- Q: How does the servo motor drive work

- Servo driver: (servo drives) is also known as "servo controller and the servo amplifier, a controller is used to control the servo motor, its action is similar to the frequency converter applied to ordinary ac motor, belonging to the part of the servo system, mainly used in high precision positioning system. Typically by location, speed and torque three ways to control the servo motor, high precision positioning of transmission system, is currently the transmission technology of high-end products. How it works: The current mainstream servo drives are controlled by digital signal processors (DSP). It can implement the more complicated control algorithm, realize digitization, network and intelligence. Power devices are widely used in intelligent power module (IPM) as the core design of drive circuit, IPM internal integrated drive circuit, at the same time has the overvoltage, overcurrent, overheating, under-voltage protection circuit, such as fault detection in the primary loop to join the soft start circuit, to reduce the impact to drive during startup.

- Q: Is the motor driven mainly by current or voltage?

- The voltage is the magnetic field that has a rotating rotor. The size of the current is determined by the wire cables of the coils, and there is a large capacitor in front of the motor. That's because the motor needs a large current at the beginning, and if the load is not heavy it can be done. Heavy words. You need a larger current. This is all determined by the W number of the motor.

- Q: How the servo driver works

- Advantages of servo to the system:1, the speed of adjustment is wide High positioning accuracy Have enough transmission rigidity and high speed stability Quick response, no overtones In order to guarantee the quality, productivity, and in addition to require a higher positioning accuracy, also requires good fast response characteristics, which requires command signal tracking response is faster, because the numerical control system at the time of starting, braking and acceleration for addition, subtraction is large enough to shorten the transition time of feeding system, reduce the contour error of transition. Low speed torque, overload ability Generally speaking, the servo actuator is more than 1.5 times the overload capacity in minutes or even half an hour, and can be over 4 ~ 6 times over in a short period of time without damage. High reliability Requirements of nc machine tool feed drive system, high reliability, good stability and strong environmental adaptation, such as temperature, humidity, vibration, and strong anti-interference ability.

- Q: How many drivers do you need for a few steps?

- If you have two motors that are in sync or in the opposite direction, the other speed is consistent with the motion, you can drag two or more. But there is a possibility of burning motors. Because drives the output current of certain, if a drive with multiple motors is bound to the current amplification of many, once the line fault, the total current is applied to a motor, so are likely to burn out motor, so don't recommend this.

- Q: How do you measure the output current of the step motor driver

- A series of current in one phase of the continuous running of the machine can be seen in one phase. In the phase line, the resistance of a single one in the phase line is used to see the waveform on both ends of the resistance, and the maximum on the oscilloscope is the peak current. The current, which is marked on the attachment of the appliance, or the current that the manufacturer stipulates that the attachment of the appliance can be carried by the specified conditions. Rated current of the electric equipment refers to the benchmark environment temperature, under the condition of rated voltage, fever is less than the long-term fever allowed temperature is allowed by the maximum current for a long time. Environment temperature, allows for a long time, maximum current has a great influence, due to the installation position of environmental temperature and temperature is not necessarily the same benchmark environment, generally as a rule: when the electric equipment work when the ambient temperature is higher than 40 degrees Celsius (but no higher than 60 degrees Celsius), environmental temperature, every 1 degree increase suggested that reduce the rated current 1.8%; When the temperature of the working environment is below 40 degrees, the temperature of the environment decreases by one degree, the recommended increase of 0.5 percent of the current rate, but the maximum of 20 percent of the rated current. For example, a 1mm2 copper conductor is rated at approximately 11A (30 degrees).

- Q: Is there a ring pulse distributor in the step motor drive?

- Circular distribution can be divided into soft circular and circular distribution, the so-called soft ring distribution, is through the programming, the method of using software through high-speed triple tube, or light coupling to the motor coil voltage distribution. The hard loop assignment, which I mentioned in 3, USES a hardware driver to complete the loop allocation.

- Q: How does the three-phase hybrid step motor and actuator connect

- The problem is simple, the uvw of the step drive is connected to the three wires of the motor, and the L M is the actuation 220V single phase. Three-phase hybrid stepper motor has only three lines, which is uvw, and the three lines can take any driver uvw, and switch any two lines in the opposite direction. Some people say the problem of the sixth line, which is three in three, this you don't think, the motor manufacturer has already picked up the law, if you want to change the method you are going to get the six lines

- Q: How to use the step motor drive?

- To determine the maximum running speed of the step motor, select the breakdown drive, and make the actuator work in a subdivided state.

Send your message to us

drive electronics SK 500E - Modular frequency inverter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords