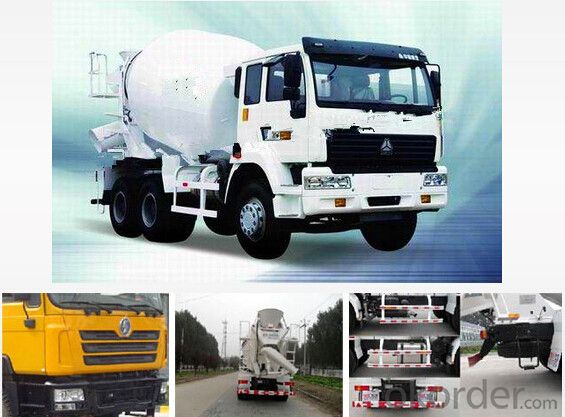

Disel Oil Concrete Mixer Truck with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: FAW Chasiss Concrete Mixer Truck with Good Quality

1. Specification

| |

Overall size (mm) | 9510 (L)*2500(W)*3930 (H) |

Tank body dimension(mm) | 5370*2300 |

Wheel base (mm) | 3800+1350 |

Tread f/r (mm) | 1939/1860 |

Max. Speed (km/h) | 90 |

Chassis | |

Manufacturer | Shacman |

Model | SX5255GJBJT384 |

Steering system | Integral power steering |

Transmission | Manual, Fast 9JS119 |

Brake system | Integral power steering |

High pressure oil pump | ARK pump |

Hydraulic motor | ARK motor |

Reducer | PMB 6.5sp |

Water supply system | Water supply by air pressure (450L water tank), homemade sprinkler. |

Air-condition | Shacman special air condition |

Engine | |

Model | WP10.336 |

Max. Power (hp) | 336 |

Engine type | 4 strokes, water cooling, turbo, EFI diesel engine |

Fuel type | Diesel oil |

Tank body parameter | |

Mixing volume(m3) | 10 optional for 6-12m3 |

Feeding speed | More than or equal to 3m3/min |

Unloading speed | More than or equal to 2m3/min |

Discharge residue rate | Less than 0.5% |

2. Application

Concrete Container and delivery.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce FAW Chasiss Concrete Mixer Truck with Good Quality according to customers request?

A4: Yes, we can produce FAW Chasiss Concrete Mixer Truck with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How many layers of steel wire tyres are used in concrete mixers

- Concrete agitator truck tyres are usually used in 18 levels of steel wire tyres, which is used in 20 levels

- Q: What is the normal speed in the transportation of the concrete mixer

- In the case of idle speed (engine speed of 600 r/min) generally feed mixing every 4 r/min, when discharging at around 6 r/min, the gas engine speed from 1500 to 2000 r/min when the hydraulic pump and motor mechanical efficiency is highest, feed mixing around 10 r/min, when discharging 12 to 14 r/min. Speed is adjustable, through adjust the driving torque of each point, can make the speed increase or decrease, when the stirring speed too fast will affect the service life of the hydraulic system, general stirring speed in the process of transportation for the 3 revolutions per minute.

- Q: Is it possible to mix the concrete in a mixing truck for eight hours?

- When the concrete is removed from the mixture, it is best not to exceed 150min according to the temperature. But now with the development of the additive technology, and high performance concrete initial setting time and perhaps even control to 13-15 hours (Shanghai world financial center base raft concrete). You can discriminate in this way. Concrete stirred 8 hours, not casual water, workability change is not very big, can use, but 1 can back, part of discharge, stir some higher than the another two grades of concrete, quick stir for a few minutes and pouring into the part or not is not very important part of the bearing. According to the admixture, add admixtures, whisk for 3-4min, and reduce the use of one or two grades. If you have added a lot of water to the site, there has been a significant change in the ease of use.

- Q: How many years does the concrete agitator truck go away?

- Usually use life for 8 to 10 years, but there is no special provision for discarded concrete transporter, is generally in accordance with the provisions of other vehicles in the motor vehicle standards: use fixed number of year for 10 years, can carry out the delay to 4 years. Because of concrete transport vehicle is a special vehicle, this is generally will have certain preferential treatment for scrap.

- Q: How does the concrete mixing truck work?

- Working principle is that by taking power device to take out car chassis power, and drive hydraulic system of the variable pump, the mechanical energy into hydraulic energy to quantitative motor, motor and drive reducer, driven by speed reducer mixing plant, for mixing concrete

- Q: s the collapse of four concrete mixer trucks

- Do you mean the concrete can be transported by the concrete mixer? If that's the case, then I say clearly, no, it's a problem that the slump is put in and out of the car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, and the best way to do it is to search for it.

- Q: What are the three main parts of the concrete mixer car

- The three main parts of a concrete mixer are oil pump, motor and speed reducer. The function of oil pump: provide constant power for hydraulic oil. The function of the motor: converts the power of the hydraulic oil into mechanical power and is transmitted to the decelerator. Decelerator: reduce the speed of the hydraulic motor

- Q: How did the concrete agitate the concrete

- By rotating the concrete from the tank through a turbine fan, it can control the gears to adjust the speed of the material.

- Q: What is the driving license for a concrete mixer truck?

- B2, you can do it directly. But it must be 21 years old and must be taught in permanent residence. The temporary residence is limited to the C series. The tuition fee for Beijing is 2,800 to 3100.

- Q: Why is the concrete mixer turning on the road?

- Prevent concrete from being isolated and make concrete more uniform. In addition, the concrete is in a state of stagnation for a long time, and the vehicle shakes and the concrete will soon be compacted, and the pot will not move.

Send your message to us

Disel Oil Concrete Mixer Truck with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords