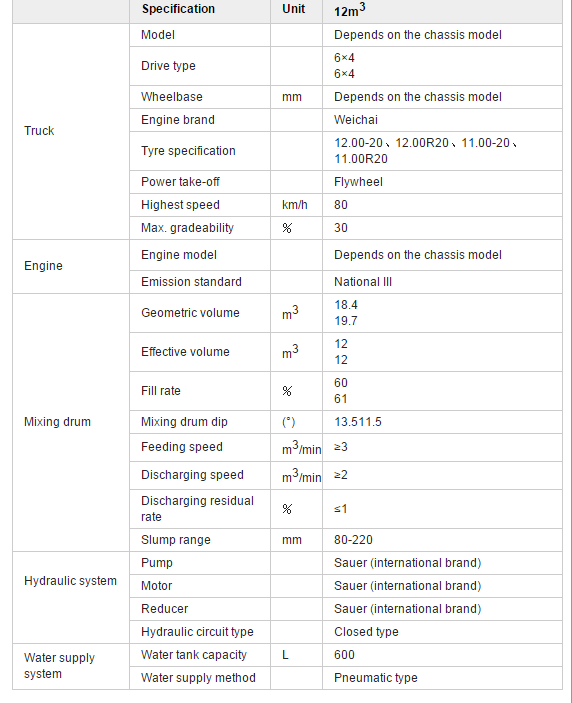

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

12m³ Concrete truck mixer / ISO & CE certificate

Specification

Hydraulic system

•The split hydraulic system features low cost and easy maintenance;

•The best hydraulic system assembly in the world.

•The company has good relationship with leading hydraulic system manufacturers. The hydraulic system is the most reliable, featuring compact structure and easy maintenance.

•The hydraulic pump suspension frame adopts U type bolt fixing, featuring good interchangeability and easy maintenance; It adopts Sauer hydraulic oil pump, motor and reducer.

Water supply system

•Large water tank capacity; One-time water using cycle is long;

•Pneumatic type water supply; Washing system, high water supply pressure, clean the feeding hopper and, discharging slot, tank and other equipment;

•One switch on the bottom of the cleaning system, which can discharge the water completely in winter.

•The water pump and shower nozzle are arranged reasonably, which are easy to operate.

Operation system

•It adopts the control method of mechanical linkage, and optimize the traditional operation structure, which is easier and more reliable for the operator.

•The cab adds the internal operation handle, which is easy for operation without getting off.

•Control the mixing and discharging speed by the throttle, and load (acceleration) and unload (acceleration) the material.

•Optimize the operation reliability, and eliminate the safety loophole.

Feeding and discharging system

•Add the quick coupler for watering, and the optimized hopper is easy to feed and discharge the concrete;

•The feeding height of less than 3850mm is suitable for the mixer, and the upper of feeding hopper is less than 650mm;

•The discharging height of 1350mm-1550mm is suitable for the feeding inlet of the pump;

Upper electrical system

•The electrical system is in single line, with negative pole on iron. The line voltage is 24V.

•The electrical system consists of illuminator, hydraulic oil temperature control switch, relay, and fan motor. When the oil temperature is over 60°C, the temperature control switch will connect and the cooling fan will rotate; when the oil temperature is below 55°C, the temperature control switch will disconnect and the cooling fan will stop.

•The work lamp switch controls the work lamp.

- Q: What is the normal speed in the transportation of the concrete mixer

- In the case of idle speed (engine speed of 600 r/min) generally feed mixing every 4 r/min, when discharging at around 6 r/min, the gas engine speed from 1500 to 2000 r/min when the hydraulic pump and motor mechanical efficiency is highest, feed mixing around 10 r/min, when discharging 12 to 14 r/min. Speed is adjustable, through adjust the driving torque of each point, can make the speed increase or decrease, when the stirring speed too fast will affect the service life of the hydraulic system, general stirring speed in the process of transportation for the 3 revolutions per minute.

- Q: Is it possible to mix the concrete in a mixing truck for eight hours?

- The concrete was stirred in the blender truck for eight hours and if it was added, there was no problem. In the case of not add water to let out a bit to see, if haven't lost the plastic concrete, slump of qualified, can continue to use, otherwise, had to be abandoned, or as aggregate, points repeatedly to stir.

- Q: What is the car for concrete

- It is called mixer truck concrete mixer truck There are also some people called muck mixer truck

- Q: How does the concrete mixing truck work?

- Operating mechanism (1) control the rotating direction of the mixing cylinder so that it is rotating in the process of feeding and transportation. (2) control the speed of the mixer. The mixing device consists mainly of the mixer and its auxiliary supporting parts. Mixing drum of concrete loaded containers, rotates the concrete along the blade spiral direction, constantly in the process of ascension and turning by mixing and stirring. In the process of feeding and transportation, the mixing cylinder is turning, the concrete is moving in the blade, and the mixing cylinder is turned and the concrete is removed out of the blade. The blades are the main parts of the mixing plant, and the damage or severe wear and tear can cause the concrete to be mixed. In addition, if the design is unreasonable, the concrete will be isolated

- Q: Is a tanker and a mixer a thing

- Usually a concrete mixer is called a tanker But the tanker also has a concrete factory that transports the bulk cement, and USES the long can to drag the engine

- Q: What are the three main parts of the concrete mixer car

- Oil pump, motor, speed reducer... Please do not hesitate to adopt

- Q: How did the concrete agitate the concrete

- When pouring into the mixing building, the two sides of the car are equal to the stirring bracket, and the first time the mouth is made a mark, so that the next time it will be successful!

- Q: How many cars do you have for a concrete tanker

- Now the concrete agitator truck is generally measured in the quantity of tank, usually from six square cans to 18 cans, and now it is commonly used in 10-15 cans.

- Q: What is the purpose of the concrete mixer

- You're not going to give it to you, right?so i do not ansewr you

- Q: What is the difference between a concrete mixer and a tanker?

- Concrete mixers are also called concrete mixers, and they are called concrete transporters, which are actually a kind of thing.

Send your message to us

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords