DIN934 Hex Nut M1.6 -M33

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

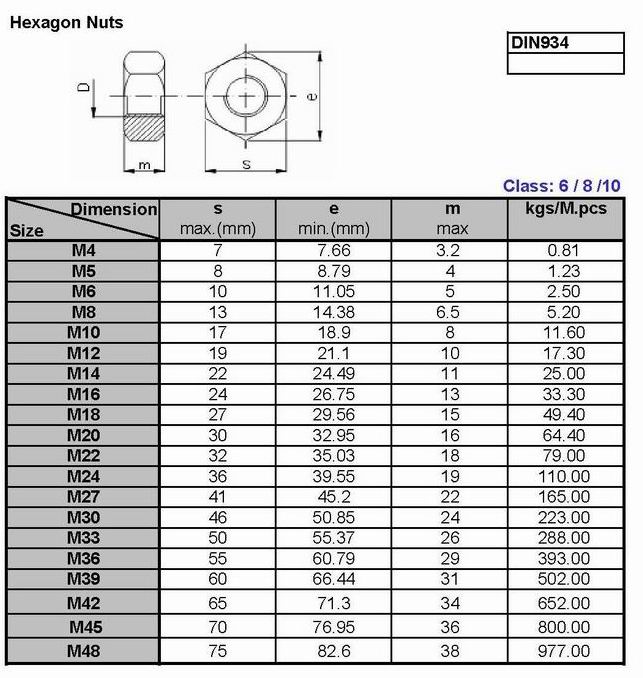

Product Name | DIN934 Hex Nut M1.6 -M33 |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M1.6--M33 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q: What is the role of flat washers? There is a friend who can introduce

- to Increase the stability factor to make it more stable

- Q: Screws are not slopes.

- Can not simply say whether it is a specific analysis of specific issues

- Q: What are the advantages and disadvantages of car audio modification, wood washer and plastic washer?

- Wood washer: divided into three plywood and MDF, they are afraid of water. In particular, the density board, see water expansion, brush waterproof, on the line. Advantages: can make the desired shape, there is no resonance.Plastic gasket defects: fixed shape, difficult to modify, there will be a little resonance, the advantages of super waterproof.If the horn is mounted directly on the plate, it is easy to cause resonance. This resonance will seriously deteriorate the quality. When the speaker vibrates, it will drive the steel plate to vibrate. Therefore, the main purpose of the installation of wood pad is to reduce the resonance, the installation of speakers more solid.

- Q: How do you choose the appropriate gasket for bolt or screw connection?

- Mainly depends on your needs, such as the bolt is M10, you have to choose the matching. A variety of information can be found from the hardware manual.

- Q: Was rusty rust, the screwdriver are turning how to do, is a very important thing

- Red: some of the top of the device screw corrosion to take shape, can not use wrenches, wire clamp discharge, both the impact method. First with a hammer and through the top of the cone in the vertical direction of the screw impact of a v-shaped groove. Then, adjust the chuck angle, along the direction of the screw out of the impact, see Figure 2. To be loose, you can use the wire clamp to screw out the screw. "A" or "ten" when the screw slide, you can also use this method, combined with the wire clamp screw out the screw.

- Q: In the fastener industry, 1018 refers to what material

- Low carbon steel, generally used for the production of self-tapping screws and screws and other low-strength fasteners products. 1018 steel chemical composition percentage: carbon C: 0.17-0.24; manganese Mn: 0.7-1.0; nickel Ni <= 0.25; phosphorus P: <= 0.035; sulfur S: <= 0.035; silicon Si: 0.17-0.37; <= 0.25; copper Cu: <= 0.25 domestic commonly used 18A and 22A material, carbon 0.18%. Domestic steel mills are now used daily SWRCH18A

- Q: Why should the screw twist clockwise?

- Because the screw on the original flute is the clockwise direction of it

- Q: Is it hard to heat the fasteners?

- Fasteners are a kind of standard parts, and their requirements are often higher than other standard parts, but heat treatment is better

- Q: Why are the screws of the screw?

- The threads are divided into connecting threads and drive threads. Which in addition to connecting the thread to remove the common thread but also non-threaded sealed pipe thread, threaded thread with the thread and metric taper thread.

- Q: What is the invention of the screw?

- Hello hello as early as 2000 years ago appeared, but it will be used for fixed objects to be delayed until about 500 years ago. The first person who describes the spiral is the famous ancient Greek scientist Archimedes, which uses a wooden bucket to make a spiral object used to extract water from one plane to another plane for irrigation. By the middle of the Middle Ages, craftsmen used wood nails or metal nails to connect the wood structure of the building. This should be the real predecessor of the screw. In the 16th century, people began to produce spiral nails. And to the 18th world, people began a large-scale production of fastening objects with a screw nail. The afternoon is helpful to you

Send your message to us

DIN934 Hex Nut M1.6 -M33

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords