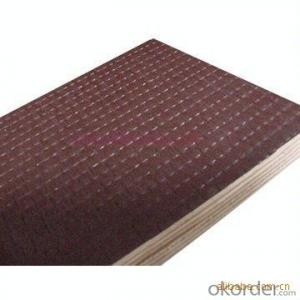

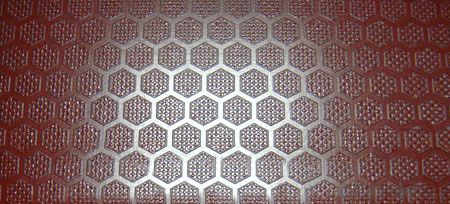

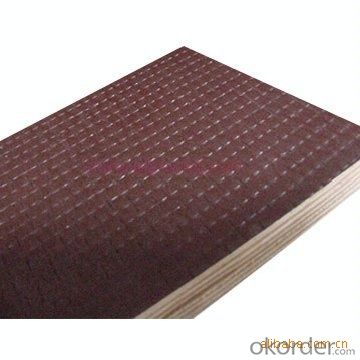

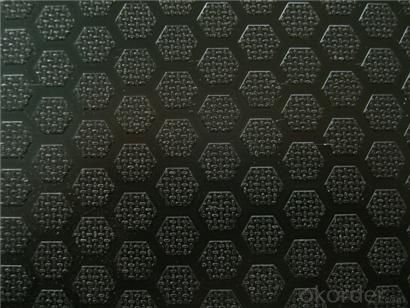

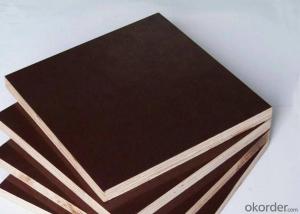

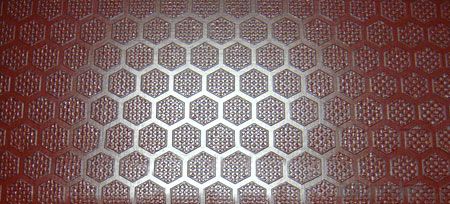

4x8 Diamond Design Anti-Slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification

Anti-slippery film faced plywood

Size:1220X2440mm ,1250X2500mm

Glue:MR,WBP

Core:poplar,hardwood,combi

F/B:balck,brown,red

Description

Size: | 1220*2440cm or as request |

core | poplar,pine,birch,hardwood,etc |

Film | black film |

Face | film faces one sides or two |

Feature | strong nailing strength and easy to be coated |

Processing of pressing | Third or second |

Determination of gule strength | 2.96Mpa |

Moisture content | 7-15% |

Elastic modulus | 5000-6000mPA |

Features:

1. No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2. Good performance and more turnover use time.

3. It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4. Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5. This can moderate and contact 30% time for a project.

6. Corrosion resistant and ir will nor pollute the surface of concrete.

7. It is good to keep performance warm,ia favorable to make constrution in winter.8. Products can be made into warping plywood

9. It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different types.

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: Now what is the market for plywood development?

- From January to November 2007, China's plywood manufacturing industry achieved a total industrial output value of 101,828,484 thousand yuan, an increase of 48.27% over the same period last yea

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- partition panel, the board formed by drilling a variety of patterns, the surface spraying a variety of coatings, decorative effect is better

- Q: What is the best way to fix multi-layer plywood?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood. T

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: Multilayer board, also known as three plywood and plywood

- . Its main advantages and disadvantages of raw materials, Liu An core 1.2m.4m each board price of 10-20 yuan. And the peach core and poplar will be cheaper.

- Q: What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is made of natural wood decorative veneer affixed to the plywood made of wood-based panels.

Send your message to us

4x8 Diamond Design Anti-Slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords