Deformed Steel Bar, Steel,Hot Rolled Steel Structure,China Manufacture H500B 12M

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | in bundles or as customer's requirement |

| Delivery Detail: | Within 30days after receiving your deposit or copy of L/C |

Specifications

Hot Rolled Steel Rebar HRB 500B

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

Product Description

| Name | Steel,Hot Rolled Steel Structure,Deformed Steel Bar,China Manufacture H500B 12M |

| Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

| Grade | HRB500B |

| Diameter | 12mm-40mm |

| Length | 6-12m |

| Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

| Tolerance | As the standard or as your requirement |

| Application | Building, construction, road, bridge,etc |

| Certificated | BV |

| MOQ | 500tons per size steel rebar |

| Packing details | Steel rebar packed in bundle or as your requirement |

| Delivery | Within 30 days after deposit |

| Payment | T/T or L/C |

Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥570 | ≥14 | ||||||

Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

| 6 | 28.27 | 0.222 | 2.664 | 375.38 |

| 8 | 50.27 | 0.395 | 4.74 | 210.97 |

| 10 | 78.54 | 0.617 | 7.404 | 135.06 |

| 12 | 113.1 | 0.888 | 10.656 | 93.84 |

| 14 | 153.9 | 1.21 | 14.52 | 68.87 |

| 16 | 201.1 | 1.58 | 18.96 | 52.74 |

| 18 | 254.5 | 2 | 24 | 41.67 |

| 20 | 314.2 | 2.47 | 29.64 | 33.74 |

| 22 | 380.1 | 2.98 | 35.76 | 27.96 |

| 25 | 490.9 | 3.85 | 46.2 | 21.65 |

| 28 | 615.8 | 4.83 | 57.96 | 17.25 |

| 32 | 804.2 | 6.31 | 75.72 | 13.21 |

| 36 | 1018 | 7.99 | 98.88 | 10.43 |

| 40 | 1257 | 9.87 | 118.44 | 8.44 |

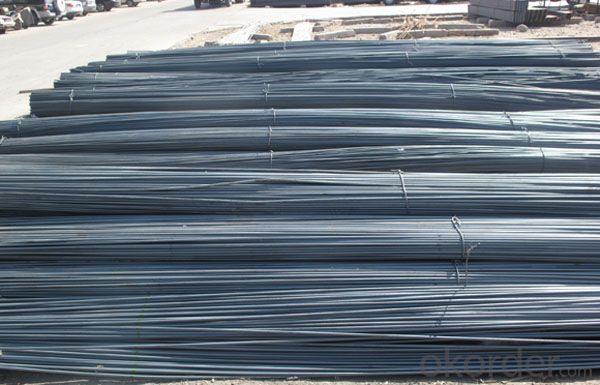

Product Picture

- Q: How long do steel rebars last?

- Steel rebars have a lifespan of approximately 50 to 100 years, depending on factors such as environmental conditions, maintenance, and quality of the steel.

- Q: What are the different surface finishes available for steel rebars?

- There are several surface finishes available for steel rebars, including plain, deformed, epoxy-coated, galvanized, and stainless steel.

- Q: How do steel rebars reinforce concrete?

- Steel rebars reinforce concrete by providing additional strength and stability to the structure. When concrete is poured, it is strong in compression but weak in tension. Steel rebars are embedded within the concrete to counterbalance this weakness and enhance its tensile strength. The rebars act as a reinforcement by absorbing the tensile forces that occur when a structure is subjected to bending or stretching. When such forces are applied, the rebars distribute the load across the concrete, preventing cracks and failure. This is crucial in structures such as buildings, bridges, and dams, where the concrete needs to withstand various external forces. The rebars also help to control the expansion and contraction of the concrete due to temperature changes. Since steel has a similar coefficient of thermal expansion as concrete, it helps to minimize the stress that occurs due to temperature fluctuations, reducing the risk of cracking. Moreover, the bond between the steel rebars and the concrete is essential for effective reinforcement. The rough surface of the rebars provides an excellent grip with the surrounding concrete, ensuring that they work together as a composite material. This bond enables the transfer of stress from the concrete to the rebars, enhancing the overall strength and durability of the structure. In summary, steel rebars reinforce concrete by adding tensile strength, distributing loads, controlling temperature-induced stress, and creating a strong bond with the concrete. This combination of concrete and steel creates a reinforced concrete structure that can withstand various external forces and maintain its structural integrity over time.

- Q: Can steel rebars be used in temporary structures?

- Yes, steel rebars can be used in temporary structures. They are commonly used in construction projects for their strength and durability, regardless of the structure's permanence.

- Q: How are steel rebars used in the construction of water treatment plants?

- Steel rebars are commonly used in the construction of water treatment plants to reinforce concrete structures such as tanks, pipelines, and basins. These rebars provide additional strength and durability to the concrete, allowing it to withstand the harsh operating conditions and the weight of water storage and treatment equipment.

- Q: Can steel rebars be used in high-rise buildings?

- Yes, steel rebars can be used in high-rise buildings. Steel rebars are commonly used as reinforcement in concrete structures, including high-rise buildings, to increase their strength and durability. The use of steel rebars helps to distribute the load and enhance the structural integrity of the building, making them a suitable choice for high-rise construction.

- Q: How do steel rebars impact the overall cost of a construction project?

- The overall cost of a construction project can be greatly influenced by steel rebars. To begin with, the price of steel rebars themselves can be quite substantial, especially if large quantities are needed. Various factors such as market demand, availability, and fluctuations in raw material prices can affect the prices of steel rebars. Additionally, the installation of steel rebars incurs extra expenses, including labor, tools, and equipment. Skilled workers are necessary to accurately position the rebars according to the construction plans, which can raise labor costs. Moreover, specialized tools and equipment are required to cut, bend, and tie the rebars, increasing the project's expenses. The use of steel rebars also impacts the construction timeline, which in turn affects the project's cost. Construction projects often have strict deadlines, and any delays in the delivery or installation of rebars can result in additional expenses due to increased labor costs, idle equipment, and potential penalties for late completion. Furthermore, steel rebars play a vital role in providing structural strength and durability to the building. By reinforcing concrete structures, steel rebars enhance their ability to bear loads and resist forces such as earthquakes and extreme weather conditions. This reduces the risk of structural failures and the need for expensive repairs or replacements in the future. In conclusion, steel rebars have a significant impact on the overall cost of a construction project due to their purchase cost, installation expenses, effect on the construction timeline, and long-term benefits in terms of structural integrity and durability. Proper planning, procurement, and installation of steel rebars are crucial for effectively managing costs and ensuring the successful completion of the project within the allocated budget.

- Q: What are the different types of steel rebars used in railway construction?

- There are primarily two types of steel rebars used in railway construction: plain carbon steel rebars and epoxy-coated rebars. Plain carbon steel rebars are commonly used due to their high strength and durability. Epoxy-coated rebars, on the other hand, are used in areas prone to corrosion, as the epoxy coating provides an additional layer of protection against moisture and other corrosive elements.

- Q: How are steel rebars anchored into concrete?

- Steel rebars are anchored into concrete by using various methods such as overlapping, mechanical anchoring devices, or by using concrete cover.

- Q: How are steel rebars recycled after demolition?

- Steel rebars are typically recycled after demolition by first separating them from other demolition debris. The rebars are then collected and transported to a recycling facility where they are processed. This process involves cleaning, cutting, and sorting the rebars to remove any contaminants. The clean and sorted rebars are then melted down in a furnace and reshaped into new steel products, such as rebars or other construction materials. Recycling steel rebars not only helps reduce waste but also conserves energy and natural resources.

Send your message to us

Deformed Steel Bar, Steel,Hot Rolled Steel Structure,China Manufacture H500B 12M

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords