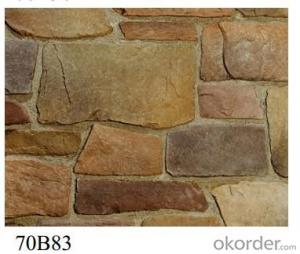

Culture stone BA 022

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

We have:

Mushroom stone series

Hometown reef series

Scattered stone series

Reef rock stone series

Nangai reef series

Water washed stone series

Mixed stone series

Antique brick series

It can be used by outdoor or indoor building materials

Delivery time is 20 days after you confirm the order

TT or LC payment is available for us.

Material: Reef rock stone series

Size can be adjusted according to customers' requirements.

- Q: Logs, lumber (square wood, plate, specifications) from what kind of tree species, what characteristics, mainly used for what type of wood structure, the specification is how to grade?

- Wood refers to the already skin, roots, treetops of wood, and has been processed according to a certain size into the diameter and length of the material. Sawn timber, also known as corridor, plate; that is, according to a certain standard specifications or size of the re-processing molding. Conifers, broadleaf trees (such as various types of pine, cedar, cypress, camphor, ash, etc.) can be processed into logs and sawn timber. Conifers generally trunk straight and tall, smooth texture, uniform material, high strength, bulk density and expansion shrinkage smaller, better corrosion resistance. Is the main building materials, can be used as load-bearing components, furniture and so on. Broadwood tree trunk straight part of the general is relatively short, hard material, more difficult to process, heavier, swelling, warping deformation, easy to crack. Often used as a smaller component. Some tree species are beautiful, suitable for interior decoration, furniture and plywood. Wood structure of the specification of the wood to allow the stress level and elastic modulus are clear values, it is recommended to consult the specification.

- Q: 2017 plate top ten brands

- China top ten gypsum board brand 1 king coconut (China's well-known trademarks, the Chinese brand 500, China's top ten brands of wood, the first Chinese woodworking board brand, Hangzhou King coconut holding) 2 Albert CHAN (Guangdong famous brand, specializing in the production of environmentally friendly plywood wood products of large enterprises, Guangzhou City is Granville Wood Products Co., Ltd.) 3 Tailmei (German technology, German equipment, China 's top ten gypsum board brand, China' s environmental labeling product certification, Hubei famous brand. 4 North New Building Materials (China Famous Brand, China Top Ten Gypsum Board Brand, China Top Ten Brand, China Famous Brand, China Gypsum Board Industry First) 5 Lafarge (green building materials, Lafarge Group (French brand), Lafarge has the world's leading building materials R & D facilities) 6 Taishan (China Famous Brand, China Famous Brand, Taishan Gypsum Co., Ltd. is a national key new building materials production enterprises) 7 Saint-Gobain (global gypsum board share first, global gypsum powder share first, global ceiling share third, Saint-Gobain Group) 8 can be resistant (top ten gypsum board brand, Germany can be resistant to international companies with its innovative solutions to occupy the industry leading position from the development) 9 Jason (top ten gypsum board brand, green building materials, Jason gypsum board group company to invest in China, serve the global construction market!) 10 Bayer (Shandong brand name products, top ten gypsum board brand, Shandong Bayer Group for the human to create a beautiful living environment)

- Q: Is the PS board not an acrylic board?

- Introduction to Acrylic Acrylics Acrylics and Acrylic Acrylic Acrylic Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Acrylics Including the monomer, sheet, pellets, resin and composite materials, the acrylic plate from the methyl methacrylate monomer (MMA) polymerization, that is, polymethyl methacrylate (PMMA) sheet plexiglass, "organic Glass "is derived from the trade name" Oroglas "(a PMMA board) from" Organic Glass "(ie, plexiglass). But in recent years because all by the transparent plastic such as PS, PC, etc. are collectively referred to as plexiglass. PS sheet polystyrene (PS) extruded sheet visible material is different, the nature is similar

- Q: What about the quality of the new millennium?

- This time you count the people, and my house when the house I studied the whole plate over time, the new millennium plate in general is a large manufacturers of products, in the high-end look, there is also a king coconut brand (first-line brand ), The new millennium is an economic series, the price is much cheaper than the bunny Moganshan millennium boat, the quality of these brands is almost the same, even better, because after all, the product is their own manufacturers, unlike those big brands, some products Not their own production, to go to the small factory to find almost OEM, environmental protection can not guarantee ,,, the new millennium home with a very appropriate, and now have E0 and E1 level, environmental protection coefficient is fully standard, miscellaneous brands and small factories of the most Do not use, even if the quality can be, but the environmental protection factor is certainly not up to the standard.

- Q: I heard that the overall customer closet is a high density board, and in Sophie is the MDF, is it true that the two plates in the end which is good, the price?

- Good guest service is open-minded, say what the market is only our home and another do MDF wardrobe, other home with particleboard. In fact, particleboard is much better than the density board, whether it is moisture, stability, environmental protection are better than the MDF, MDF is a glue to stick to a piece of industrial debris. Good guest off the density board wardrobe price is still much higher than the particleboard, I am wondering how professional to do the overall wardrobe brand how to do with the difference between particleboard and MDF do not know, still price consumers. Yesterday had just seen a good guest, the waiter pulled very much, would like to consult a few questions are always disdain that we all 600 stores! Give the impression that the "shop big bully", 600 shop great Kazakhstan, on this service attitude, not to mention the money has not paid, after paying the money is not more arrogant, seriously despise this shop! The

- Q: Is there any color of a decorated panel

- There are many types of ornaments, such as white oak, safflower pear, red oak, etc., each color, pattern is not the same, to choose a wide surface, you can meet the different preferences.

- Q: Plate furniture formaldehyde release national standard is

- The state for the wooden furniture, the release of harmful substances have a clear mandatory provisions, including plate furniture formaldehyde emission limit of ≤ 1.5mg / L.

- Q: Guangzhou red cotton plate and ordinary moisture board What is the difference

- My home wardrobe is made of red cotton plate, there is no pungent taste.

- Q: Daren detailed explanation VCM color plate and PCM color plate difference, for the refrigerator panel

- VCM board for the film, PCM for the color coated board, the general VCM board with galvanized substrate, covered with color or pattern film, the surface of such a plate is very smooth, the surface color effect is PCM can not be achieved, but the price More expensive, generally used in the refrigerator panel, or high-end wine cabinet side panels, set-top box shell, product use for the membrane requirements have a relatively high demand. PCM is a color pre-coated sheet, the surface for home appliances environmental protection paint, the price is relatively cheap compared to PCM, generally used in the refrigerator side panels, this plate is not suitable for high-grade refrigerator panel, due to the flatness of the plate than VCM difference and color The effect is single, so the main use of the side panels.

Send your message to us

Culture stone BA 022

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords