Construction Hoist SCD270 Counterweight 33m/min

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of SCD270 Construction Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Main Parts of SCD270 Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

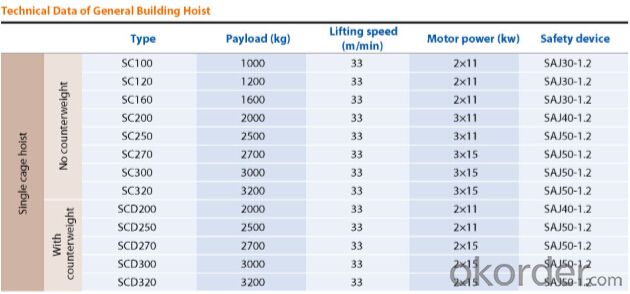

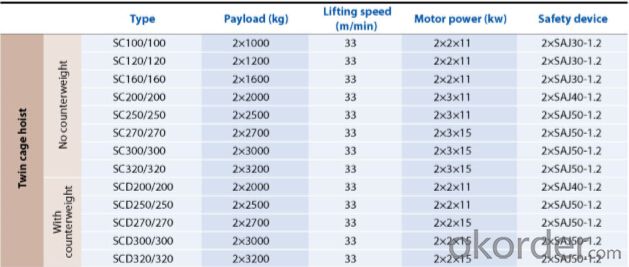

SCD270 Construction Hoist Specifiction

FAQ of SCD270 Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: Is it possible to utilize a building hoist for the purpose of lifting small tools and equipment?

- <p>Yes, a building hoist can be used for lifting small tools and equipment, provided it is within the hoist's weight capacity. It's important to ensure that the items are securely fastened to prevent any accidents during lifting. Always follow the manufacturer's guidelines and safety regulations when using a building hoist for any lifting tasks.</p>

- Q: Is it possible to utilize a building hoist for elevating construction materials?

- <p>Yes, building hoists are commonly used in construction to lift materials. They are designed to transport heavy materials, such as bricks, cement, and steel, vertically between floors. These hoists are crucial for efficient construction, especially in high-rise buildings, as they reduce manual labor and increase safety by minimizing the need for workers to carry heavy loads up ladders or stairs.</p>

- Q: This question asks for a comparison between electric and manual lifting equipment, highlighting their distinct features and operational differences.

- <p>Electric lifting equipment, such as electric hoists and cranes, operates using electrical power and is designed for heavy-duty lifting and repetitive tasks. It offers high efficiency, ease of use, and often requires less physical effort from operators. On the other hand, manual lifting equipment, like levers, pulleys, and manual hoists, relies on human power and is typically used for lighter loads or in situations where electrical power is not available. Manual equipment is generally more portable and requires no power source, but it is slower and more labor-intensive. Electric equipment is more suitable for industrial settings, while manual equipment is often used in smaller-scale operations or for temporary tasks.</p>

- Q: This question asks for the proper steps to install a building hoist, a device used in construction to lift materials and workers.

- <p>To install a building hoist correctly, follow these steps: 1) Ensure the site is suitable and inspect the hoist for any damages. 2) Assemble the hoist tower on a solid, level base. 3) Install the mast and guide rails according to the manufacturer's instructions. 4) Attach the hoist mechanism and cab, ensuring all connections are secure. 5) Conduct a thorough inspection and test the hoist's functionality. 6) Obtain necessary permits and inspections from local authorities. 7) Train operators on the safe use of the hoist. Always adhere to safety guidelines and manufacturer's specifications.</p>

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: What are alternative uses for a building hoist besides construction?

- <p>Yes, a building hoist can be used for purposes other than construction. It can be utilized for moving heavy equipment in industrial settings, transporting goods in warehouses, or even in emergency services for rescue operations. Its ability to lift and lower heavy loads makes it versatile for various applications where vertical transportation is required. However, it's crucial to ensure that any alternative use complies with safety regulations and the hoist's operational specifications.</p>

- Q: Describe the process of utilizing a computer control system for operating a building hoist.

- <p>To use a computer control system for a building hoist, first ensure the system is properly installed and integrated with the hoist's mechanical and electrical components. Begin by powering on the control system and checking for any error messages that might indicate a problem. Once the system is ready, input the desired parameters such as load weight, lifting height, and speed settings. Use the control panel to initiate the hoist's movement, monitoring the progress on the system's display. Adjust the hoist's operation in real-time as needed, ensuring safety protocols are followed. Regularly check system diagnostics for maintenance alerts and address any issues promptly to maintain optimal performance.</p>

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: This question asks about the time required to install a building hoist, a device used for lifting materials in construction.

- <p>The time it takes to install a building hoist can vary significantly based on factors such as the type and size of the hoist, the specific building requirements, and the experience of the installation team. On average, it can take anywhere from a few hours to a couple of days. For smaller hoists, installation might be completed within a day, while larger, more complex systems could take longer. It's important to note that safety checks and regulatory compliance verifications are also part of the process, which can add to the total installation time.</p>

Send your message to us

Construction Hoist SCD270 Counterweight 33m/min

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords