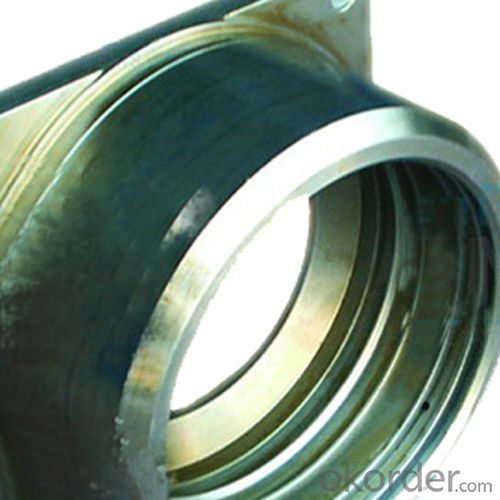

Concrete Pumps Spare Parts Outer Housing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

The Concrete Pumps Spare Parts Complete Outer Housing normally made by special steel materials, according to customer’s requests, and also package in plywood box and put into container.

Scope of Application of the pipes

The Concrete Pumps Spare Parts Outer Housing is a concrete pumps parts for combined use with other concrete parts in for concrete pumps and truck pumps. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This pipes can only be used in concrete construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

OKorder's Concrete Pumps Spare Parts Outer Housing Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (5-10 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

Specifications:

CNBM No. | 2000024 |

Original No. | 240391003 |

Description | Outer Housing |

Remark |

FAQ:

Q1: How long about delivery time Concrete Pumps Spare parts Outer Housing ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Concrete Pumps Spare Parts Outer Housing ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically 7 to 30 workdays.

Q4: If we can produce some Outer Housing according to customers request?

A4: Yes, we can produce Outer Housing according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: How can a malfunctioning remote control affect the pumping operation?

- The pumping operation can be significantly affected in multiple ways by a malfunctioning remote control. Initially, operators utilize the remote control to operate the pump from a distance, enabling them to control crucial settings such as speed and direction. If the remote control malfunctions, it can hinder operators' ability to effectively control the pump, resulting in delays or inefficiencies in the operation. Furthermore, a malfunctioning remote control can lead to inconsistent or erratic commands being sent to the pump. This instability in commands can cause fluctuation in flow rates, pressure, or other critical parameters, thereby impacting the overall efficiency and effectiveness of the pumping operation. Moreover, there are safety risks associated with a malfunctioning remote control. If the remote control fails to transmit accurate commands, it may cause the pump to operate at undesired speeds or pressures, potentially leading to equipment damage or accidents. Additionally, during emergencies or hazardous situations, the inability to control the pump remotely can hinder operators' prompt response and risk mitigation. Additionally, a malfunctioning remote control can disrupt the monitoring and control systems linked to the pumping operation. Remote controls are often integrated with centralized monitoring systems that provide real-time data and alerts to operators. If the remote control fails, it can interrupt the flow of critical information, making it challenging for operators to monitor the pump's performance, identify issues, or make informed decisions. To conclude, the malfunctioning of a remote control can adversely affect the pumping operation by impeding remote control functionality, causing erratic pump performance, posing safety risks, and hindering monitoring and control systems. Therefore, it is essential to regularly inspect and maintain remote controls to ensure their proper functionality and minimize any potential disruptions to the pumping operation.

- Q: Can I get spare parts for both concrete pumps with and without emergency stop systems?

- Yes, spare parts are available for both concrete pumps with and without emergency stop systems. These spare parts can be sourced from authorized dealers or manufacturers, ensuring the proper functioning and maintenance of both types of concrete pumps.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- To minimize downtime during the replacement of concrete pump spare parts, it is crucial to follow a few key steps. First, ensure that you have a comprehensive understanding of the specific spare parts required for your concrete pump. This will help you streamline the ordering process and minimize delays. Additionally, it is essential to schedule regular maintenance and inspections to identify any potential issues beforehand, allowing you to proactively replace parts before they fail. Lastly, work with a reputable supplier who can provide high-quality spare parts promptly, reducing downtime.

- Q: How can a damaged concrete pump hopper affect the pumping process?

- The pumping process can be negatively impacted by a damaged concrete pump hopper in several ways. To begin with, efficiency and productivity can decrease when the hopper is damaged. The hopper's role is to hold and feed the concrete mixture into the pump. Any damage to the hopper can disrupt the continuous flow of concrete, leading to frequent interruptions in the pumping process. This causes delays and reduces the overall output of the pump. Furthermore, the quality of the concrete being pumped can be affected by a damaged hopper. The hopper is designed to ensure proper mixing and consistency of the concrete mixture before it is pumped. If the hopper is damaged, it may not effectively mix the concrete, resulting in inconsistencies in the mixture. This can lead to poor-quality concrete being pumped, compromising the structural integrity and durability of the final product. Additionally, a damaged hopper can pose safety risks for the workers involved in the pumping process. Sharp edges or loose parts on a damaged hopper can cause injury if not addressed properly. Moreover, if the hopper is not functioning correctly, it may cause clogs or blockages in the pump, leading to pressure build-up and potential accidents. Finally, maintenance and repair costs can increase due to a damaged hopper. An imperfect hopper may require frequent repairs or even replacement, which can be time-consuming and expensive. Regular maintenance and inspection of the hopper are crucial to identify any damages early on and prevent them from escalating into more significant issues. In conclusion, a damaged concrete pump hopper has significant implications for the pumping process, including reduced efficiency, compromised concrete quality, safety risks, and increased maintenance costs. Regular inspection, maintenance, and timely repairs are essential to ensure the smooth operation of the pump and the delivery of high-quality concrete.

- Q: What are the indications of a faulty concrete pump seal?

- There are several indications that can suggest a faulty concrete pump seal. Some of the common signs include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage. If you notice any leaks around the seal area, it is a clear indication that the seal is not working properly and needs to be replaced. 2. Reduced pumping efficiency: A faulty seal can lead to reduced pumping efficiency. If you notice that the concrete pump is not able to deliver the same amount of concrete as it used to, or if it takes longer to complete a job, it could be due to a faulty seal. 3. Increased noise levels: Another indication of a faulty seal is an increase in noise levels during operation. If you notice any unusual or louder noises coming from the concrete pump, it could be a sign that the seal is not sealing properly and needs to be checked. 4. Vibration or movement: Faulty seals can also lead to excessive vibration or movement in the pump. If you notice that the pump is vibrating more than usual or if it is moving around during operation, it could indicate a problem with the seal. 5. Contamination: A faulty seal can allow contaminants such as dirt, dust, or water to enter the pump. If you notice any signs of contamination in the pump, it is important to inspect the seal and replace it if necessary. It is important to address any indications of a faulty concrete pump seal promptly to avoid further damage to the pump and ensure safe and efficient operation. Regular maintenance and inspection of the seal can help prevent potential issues and extend the life of the concrete pump.

- Q: Can I get spare parts for both concrete pumps with and without lubrication systems?

- Spare parts are available for both lubricated and non-lubricated concrete pumps. Various manufacturers and suppliers offer a diverse selection of spare parts for different concrete pump types and models. These spare parts encompass valves, cylinders, pistons, seals, hoses, filters, and more. Regardless of whether your concrete pump is equipped with a lubrication system or not, you can easily locate the required spare parts for its maintenance and repair. It is advisable to consult the manufacturer or a reliable supplier to ensure the procurement of accurate spare parts that match your specific concrete pump model.

- Q: What is the function of a concrete pump remote control?

- A concrete pump remote control serves as a tool to operate and control the functions of a concrete pump from a distance. It allows the operator to manipulate various aspects of the pump's operation, such as starting and stopping the pumping process, adjusting the speed and direction of the pump, and controlling the placement and flow of the concrete. By providing remote control capabilities, it eliminates the need for the operator to be physically close to the pump, allowing for safer and more efficient operation. Additionally, the remote control often includes features such as emergency stop buttons, diagnostics, and data logging capabilities, which further enhance the functionality and reliability of the concrete pump. Overall, the function of a concrete pump remote control is to provide convenience, precision, and safety in the operation of concrete pumping equipment.

- Q: How do I properly maintain and replace hydraulic filters in concrete pump spare parts?

- To ensure your equipment's longevity and efficiency, it is crucial to properly maintain and replace hydraulic filters in concrete pump spare parts. Here are some guidelines to follow: 1. Familiarize yourself with the manufacturer's recommendations: Understand the maintenance and replacement guidelines provided by the manufacturer. These instructions may vary based on the specific pump model and filter type. 2. Regularly inspect the filters: Conduct regular inspections to identify any signs of damage, clogging, or excessive wear in the hydraulic filters. Look out for dirt, debris, or other contaminants that may hinder their performance. Address any issues promptly. 3. Establish a maintenance schedule: Implement a regular maintenance schedule for the hydraulic filters. This should include regular inspections, cleaning, and replacement intervals. Adhering to a schedule will prevent unexpected breakdowns and keep the concrete pump running smoothly. 4. Clean the filters: If the hydraulic filters can be cleaned and reused, ensure to follow the proper cleaning procedure. This typically involves removing the filter, washing it with a suitable cleaning solution, and allowing it to dry thoroughly before reinstalling. Take care not to damage the filter during the cleaning process. 5. Replace as necessary: Over time, hydraulic filters become less effective at filtering out contaminants. It is important to replace them according to the manufacturer's recommended intervals or sooner if they appear excessively dirty or damaged. Always use genuine spare parts to ensure compatibility and optimal performance. 6. Install correctly: When replacing hydraulic filters, ensure they are installed correctly and securely. Pay attention to any seals or gaskets that may need replacement as well. Improper installation can lead to leaks or reduced filtration efficiency. 7. Monitor performance: After replacing the hydraulic filters, closely monitor the pump's performance. Watch for changes in pressure, flow rate, or unusual noises. If any abnormalities are observed, it may indicate a problem with the filter or other components, requiring further investigation. By following these steps, you can effectively maintain and replace hydraulic filters in your concrete pump spare parts, ensuring optimal performance and extending the equipment's lifespan.

- Q: What is the role of a concrete pump hopper grate spring?

- The role of a concrete pump hopper grate spring is to provide tension and support to the hopper grate in a concrete pump. The grate spring is typically made of durable and flexible material, such as steel or rubber, and is designed to keep the hopper grate securely in place while allowing it to move and flex as needed during the concrete pumping process. The hopper grate spring helps to prevent the hopper grate from becoming dislodged or damaged by the force and vibrations generated by the concrete pump. It ensures that the grate remains properly aligned and in position, allowing for the smooth and efficient flow of concrete into the pump. Additionally, the grate spring helps to reduce the impact and stress on the hopper grate, extending its lifespan and reducing the need for frequent repairs or replacements. It acts as a buffer, absorbing and distributing the forces exerted on the grate, which can be significant due to the weight and pressure of the concrete being pumped. Overall, the concrete pump hopper grate spring plays a crucial role in maintaining the integrity and functionality of the hopper grate, ensuring the safe and efficient operation of the concrete pump.

- Q: How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- To ensure the concrete pump operates efficiently and safely, it is crucial to properly maintain and replace the concrete delivery pipes in spare parts. Here are some guidelines you can adhere to: 1. Conduct Regular Inspections: Frequently check the concrete delivery pipes for signs of wear, cracks, or damage. Look out for leaks or blockages that may hinder the concrete flow. Identify weak areas that may necessitate replacement. 2. Perform Thorough Cleaning: After each use, clean the concrete delivery pipes meticulously. Use water and a high-pressure hose to eliminate any concrete residue or buildup. This will prevent clogs and maintain a smooth concrete flow. 3. Apply Lubrication: Reduce friction and prevent concrete from adhering to the inner surface of the pipes by applying a suitable lubricant. This practice will elongate the life of the pipes and guarantee a seamless concrete flow. 4. Replace Worn-out Components: Regularly monitor the condition of the delivery pipes and promptly replace any worn-out or damaged parts. Over time, the pipes may corrode or develop cracks, thereby affecting their performance. Replace these components with premium spare parts to achieve optimal outcomes. 5. Handle with Care: Exercise caution when handling the concrete delivery pipes to avoid unnecessary damage. Refrain from dropping or mishandling the pipes during transportation or storage. Shield them from extreme weather conditions and store them in a secure, dry location. 6. Prioritize Training and Safety: Ensure that the personnel operating the concrete pump are well-versed in handling and maintaining the equipment. Educate them on the significance of regular inspections, cleaning, and part replacement. Emphasize safety protocols to prevent accidents and ensure the durability of the concrete delivery pipes. By adhering to these steps, you can effectively maintain and replace the concrete delivery pipes in spare parts for the concrete pump. Consistent maintenance and prompt part replacement will extend the lifespan of the pipes and guarantee a seamless concrete flow during construction projects.

Send your message to us

Concrete Pumps Spare Parts Outer Housing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords