Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Exterior: tunnels,column covers , renovations...

(2).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

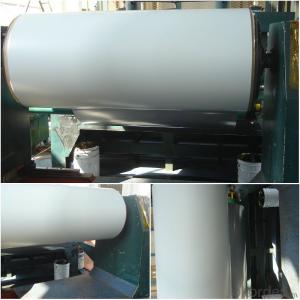

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks about the various applications of aluminum strips within the construction industry.

- <p>Aluminum strips are used in construction for a variety of purposes. They are commonly used in curtain wall systems for their lightweight and high-strength properties, providing structural support while maintaining transparency. Aluminum strips are also used in window and door frames for their durability and resistance to corrosion. In addition, they are utilized in roofing systems for their ability to withstand weather conditions and for their energy efficiency. Furthermore, aluminum strips are employed in electrical wiring and conduits due to their excellent conductivity and resistance to electrical corrosion. They are also used in the fabrication of various construction tools and equipment. Overall, aluminum strips are valued for their versatility, strength, and resistance to wear and tear in the construction industry.</p>

- Q: This question asks for the most suitable type of aluminum strip for outdoor applications.

- <p>The best type of aluminum strip for exterior use is typically 3003-H14 alloy. This alloy is known for its excellent corrosion resistance, which is crucial for outdoor applications where the strip may be exposed to various weather conditions. It also offers good formability, making it easy to shape and bend for various construction and architectural purposes. Additionally, 3003-H14 aluminum strip has good weldability, which is beneficial for applications where joining is required. It is commonly used for roofing, siding, and other exterior applications due to its durability and weather-resistant properties.</p>

- Q: Is it possible to use aluminum strips for creating jewelry or crafts?

- <p>Yes, you can use aluminum strips to make jewelry or crafts. Aluminum is a lightweight, durable, and affordable metal that is easy to shape and manipulate. It can be cut, bent, and twisted into various designs. Due to its resistance to corrosion, aluminum is also a good choice for items that will be exposed to moisture or wear. However, it's important to note that while it's versatile, aluminum is softer than other metals, so it may require additional support or reinforcement in certain applications.</p>

- Q: This question asks for the various types of insulation materials that are created using aluminum strips.

- <p>Aluminum strips are used in the production of several types of insulation materials. One common type is reflective insulation, which uses aluminum's reflective properties to reduce heat transfer. This can be found in the form of foil insulation or radiant barrier insulation. Another type is aluminum foil-backed insulation, often used in HVAC systems to prevent heat loss. Additionally, aluminum is a component in some types of flexible duct insulation, providing both thermal and acoustic insulation. Lastly, aluminum is used in certain types of thermal insulation boards, which are used in construction to provide thermal resistance. These materials are valued for their durability, resistance to corrosion, and effectiveness in thermal management.</p>

- Q: How can the aluminium band be welded to the steel shell?

- If it is more than 0.5 mm by resistance heating welding, welding materials need to use the 303B welding wire Odin wei.Welding tools: carbon block welding, welding with two electrodes.

- Q: Is it possible to use aluminum strips as a material for exterior wall cladding?

- <p>Yes, aluminum strips can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum cladding is lightweight, which makes it easier to install compared to heavier materials. It also offers excellent weather resistance and can be painted or finished in various ways to enhance the appearance of a building. Additionally, aluminum is a sustainable choice as it can be recycled, contributing to environmental sustainability.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

- Q: What types of aluminum strips are best suited for solar panel applications?

- <p>Yes, there are specific types of aluminum strips that are particularly suitable for use in solar panels. These include high-purity aluminum strips with low iron content, which are known for their excellent electrical conductivity and corrosion resistance. They are often used as busbars in solar cells to collect and transmit the generated electrical current. Additionally, aluminum strips with a high-strength alloy composition are used for structural support and frame components in solar panels due to their lightweight and durability. These aluminum strips are engineered to withstand harsh environmental conditions and maintain their integrity over the long lifespan of the solar panel.</p>

- Q: What is the minimum thickness that can be achieved when manufacturing an aluminum strip?

- <p>There is no absolute limit to how thin an aluminum strip can be made, but the practical limit is determined by the manufacturing process and the intended use of the strip. Modern technology allows for the production of aluminum strips as thin as a few micrometers. However, the thinness is constrained by factors such as material strength, ductility, and the specific application requirements. For instance, in the electronics industry, very thin aluminum strips are used for conductors, while in other applications, thicker strips might be necessary for structural integrity. The thinnest aluminum strips are often produced using techniques like rolling or extrusion, with the final thickness depending on the precision of these processes.</p>

- Q: Are aluminum strips suitable for use as an insulating material on walls?

- <p>Aluminum strips are not typically used for wall insulation. Insulation materials are designed to provide thermal resistance and prevent heat transfer, whereas aluminum is a good conductor of heat, which would not effectively insulate a wall. Instead, materials like fiberglass, mineral wool, or polystyrene are commonly used for wall insulation as they have low thermal conductivity and can effectively reduce heat transfer.</p>

Send your message to us

Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords