Stainless Steel Coils Strips Hot Cold Rolled Steel 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps ; |

Process | Hot rolled / cold rolled |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

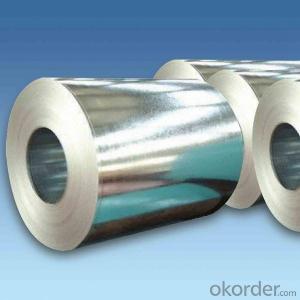

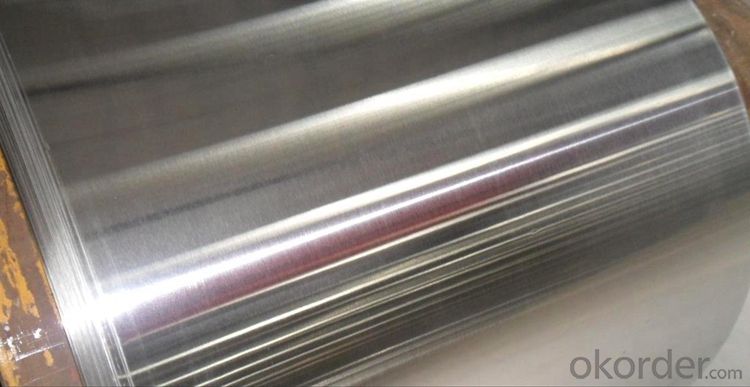

Detail picture for Stainless Steel Coils

Packaging & Delivery for Stainless Steel Coils:

Packaging Detail: Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

- Q: Are stainless steel sheets suitable for outdoor sculptures?

- Indeed, outdoor sculptures greatly benefit from the use of stainless steel sheets. This material is renowned for its durability and resistance to corrosion, making it exceptionally well-suited for enduring the harsh conditions of the outdoors. Furthermore, stainless steel exhibits remarkable resistance to rust, staining, and fading, thereby establishing itself as a low-maintenance alternative for outdoor sculptures. Moreover, stainless steel boasts a sleek and contemporary appearance, effectively enhancing the aesthetic allure of outdoor artworks. Its robustness and pliability also render it ideal for crafting intricate and elaborate sculptures. Consequently, stainless steel sheets prove to be an outstanding selection for outdoor sculptures, guaranteeing their longevity while simultaneously amplifying their visual impact.

- Q: How do you remove rust or corrosion from stainless steel sheets?

- In order to eliminate rust or corrosion from stainless steel sheets, the following steps can be followed: 1. Initiate the process by cleansing the surface of the stainless steel sheet using a mild detergent and warm water. This will eradicate any dirt or grease that may potentially impede the rust removal procedure. 2. Subsequently, ensure the sheet is thoroughly dried to prevent any further water damage and to guarantee the effectiveness of the rust removal process. 3. Proceed by utilizing a non-abrasive scrubbing pad or a soft cloth to apply a stainless steel cleaner or a homemade solution comprising equal parts vinegar and water. Gently rub the affected area in the direction of the grain of the stainless steel. 4. If the rust or corrosion persists, experiment with a paste formed from baking soda and water or a mixture of cream of tartar and water. Apply this paste to the affected region and allow it to sit for approximately 15 minutes. Then, delicately scrub the area with a soft cloth or a non-abrasive scrubbing pad. 5. If the aforementioned methods do not completely eliminate the rust or corrosion, consider using a commercial rust remover specifically formulated for stainless steel. Make sure to adhere to the manufacturer's instructions and adopt suitable safety precautions. 6. Once the rust or corrosion has been eradicated, rinse the stainless steel sheet thoroughly with clean water and completely dry it to prevent any water spots or further damage. 7. To prevent future rust or corrosion, it is advisable to regularly clean and maintain stainless steel surfaces using non-abrasive cleaners and avoiding harsh chemicals or abrasive materials. Always remember to conduct a test of any cleaning solution or rust remover on a small and inconspicuous area of the stainless steel sheet prior to applying it to the entire surface, to ensure it does not cause any damage or discoloration.

- Q: How do you determine the thickness of a stainless steel sheet?

- To determine the thickness of a stainless steel sheet, there are several methods you can employ. The most common and accurate way is to use a digital or analog caliper. This instrument allows you to measure the thickness of the sheet with high precision. Simply place the caliper jaws on opposite sides of the sheet and close them until they are snug against the surface. The measurement displayed on the caliper will indicate the thickness of the stainless steel sheet. Another method is to use a micrometer, which is similar to a caliper but provides even more precise measurements. With a micrometer, you can measure the thickness of the sheet by placing the jaws on the edge of the sheet and gently closing them until they touch. The measurement displayed on the micrometer will show you the thickness of the stainless steel sheet. If these instruments are not available, you can also determine the thickness of a stainless steel sheet by referring to its specifications or manufacturer's information. Stainless steel sheets usually come with a label or tag indicating the thickness, which can be easily read and verified. In some cases, you may need to estimate the thickness of a stainless steel sheet without any measuring tools. In such situations, you can compare the sheet to known reference materials of different thicknesses. By visually comparing the sheet to these references, you can make an educated guess about its thickness. However, this method is less accurate and should only be used as a last resort.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature stainless steel sheets can withstand depends on the specific grade of stainless steel. Generally, most stainless steel grades can withstand temperatures up to around 1500°F (815°C) before experiencing significant oxidation or scaling. However, certain high-temperature grades of stainless steel, such as 310 or 321, can withstand temperatures up to 2100°F (1150°C) or even higher. It is important to consider the specific application and grade of stainless steel when determining the maximum temperature it can withstand to ensure optimal performance and durability.

- Q: Are stainless steel sheets good for pressure vessels?

- Stainless steel sheets have gained popularity as a preferred choice for pressure vessels due to their durability, reliability, and ability to meet the demanding requirements of such applications. Commonly employed, they are considered to be an excellent option. Stainless steel possesses exceptional resistance to corrosion, high strength, and commendable mechanical properties, rendering it suitable for applications that necessitate withstanding high pressures. Moreover, stainless steel exhibits remarkable heat resistance, a pivotal trait in pressure vessels where exposure to elevated temperatures is likely. It is also important to highlight that stainless steel lends itself to easy formation and welding, facilitating the fabrication of intricate shapes and designs required for pressure vessel construction. All in all, stainless steel sheets are a favored material for pressure vessels due to their ability to endure, their dependability, and their capacity to fulfill the demanding prerequisites of such applications.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets do require special handling during installation. Here are a few important considerations: 1. Avoid Contamination: Stainless steel is prone to contamination from various sources, such as carbon steel, dirt, or grease. It is crucial to ensure that the installation area is clean and free from any potential contaminants. Tools used during installation should also be clean and free from other metals. 2. Protection from Scratches: Stainless steel sheets are susceptible to scratching during installation. It is important to handle them with care and use protective coverings or wraps to prevent any scratches or damage. Additionally, using non-abrasive tools and avoiding dragging or sliding the sheets across surfaces can help maintain their integrity. 3. Proper Fixing Techniques: Stainless steel sheets are typically secured using mechanical fasteners or adhesives. It is essential to follow the manufacturer's recommendations or industry best practices for the specific installation method. This includes using the correct type and size of fasteners and ensuring they are properly tightened without over-torquing, which can cause damage. 4. Expansion and Contraction: Stainless steel sheets can expand or contract with changes in temperature. During installation, it is necessary to allow for this movement by providing adequate clearance or using expansion joints where required. Failing to account for thermal expansion can lead to buckling, warping, or stress on the sheets. 5. Avoiding Galvanic Corrosion: Stainless steel sheets should not come into direct contact with dissimilar metals, especially those with higher galvanic potential, as it can cause galvanic corrosion. Using compatible materials and insulating stainless steel sheets from direct contact with other metals can help prevent this type of corrosion. By following these special handling guidelines, stainless steel sheets can be installed correctly, maintaining their aesthetic appeal and durability over time.

- Q: What is the water absorption rate of stainless steel sheets?

- The water absorption rate of stainless steel sheets is typically very low or negligible. Stainless steel is known for its excellent corrosion resistance and impermeability to liquids, including water. Due to its unique composition and surface properties, stainless steel sheets do not readily absorb water or allow it to penetrate the material. This makes stainless steel a preferred choice for various applications where resistance to moisture is crucial, such as in the food and beverage industry, medical equipment, and outdoor structures.

- Q: What are the different types of stainless steel sheet alloys?

- There are several different types of stainless steel sheet alloys, each with their own unique properties and characteristics. Some of the most common types include: 1. Austenitic stainless steel: This is the most widely used type of stainless steel sheet alloy. It is known for its high corrosion resistance and excellent formability. Austenitic stainless steel grades include 304 and 316, which are commonly used in various industries such as food processing, pharmaceuticals, and architecture. 2. Ferritic stainless steel: This type of stainless steel sheet alloy has a higher carbon content and lower chromium content compared to austenitic stainless steel. Ferritic stainless steel is known for its good corrosion resistance and high strength. It is often used in applications where high temperature resistance is required, such as automotive exhaust systems. 3. Martensitic stainless steel: Martensitic stainless steel sheet alloys have a higher carbon content and lower chromium content compared to both austenitic and ferritic stainless steels. They are known for their high strength and hardness, as well as their good corrosion resistance. Martensitic stainless steel grades are commonly used in applications such as cutlery, surgical instruments, and turbine blades. 4. Duplex stainless steel: This type of stainless steel sheet alloy is a combination of austenitic and ferritic stainless steels. It offers a good balance of strength and corrosion resistance, making it suitable for a wide range of applications. Duplex stainless steel grades are commonly used in the chemical processing, oil and gas, and marine industries. 5. Precipitation-hardening stainless steel: This type of stainless steel sheet alloy is heat treatable and can achieve high strength and hardness through a precipitation-hardening process. Precipitation-hardening stainless steel is commonly used in aerospace and defense applications, where high strength and corrosion resistance are critical. These are just a few examples of the different types of stainless steel sheet alloys available. The choice of alloy depends on the specific application requirements, such as corrosion resistance, strength, and temperature resistance.

- Q: What are the costs of stainless steel sheets compared to other materials?

- The costs of stainless steel sheets can vary depending on several factors such as the grade, thickness, size, and finish of the sheets. Generally, stainless steel sheets tend to be more expensive than other materials like aluminum or mild steel. This is primarily due to the higher production costs and the unique properties of stainless steel. Stainless steel is known for its corrosion resistance, durability, and aesthetic appeal, which makes it a popular choice in various industries such as construction, automotive, and manufacturing. However, these desirable qualities come at a higher price point. Compared to aluminum sheets, stainless steel sheets are typically more expensive. Aluminum is a lightweight material with good corrosion resistance, but it is not as strong or durable as stainless steel. Therefore, stainless steel is often preferred in applications where strength and longevity are crucial. When compared to mild steel, stainless steel sheets are also more costly. Mild steel is a commonly used material due to its affordability, but it lacks the corrosion resistance and aesthetic appeal of stainless steel. Stainless steel is often chosen over mild steel in applications where exposure to moisture, chemicals, or harsh environments is a concern. It is important to consider the specific requirements of the project when evaluating the costs of stainless steel sheets compared to other materials. While stainless steel may have a higher upfront cost, its long-term benefits, such as reduced maintenance and replacement costs, can often outweigh the initial investment. Additionally, the unique properties of stainless steel may make it the only viable choice for certain applications, further justifying its higher cost.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The common manufacturing standards for stainless steel sheets include ASTM A240, ASME SA240, EN 10028-7, and JIS G4304. These standards specify the chemical composition, mechanical properties, tolerances, and surface finishes required for stainless steel sheets used in various industries.

Send your message to us

Stainless Steel Coils Strips Hot Cold Rolled Steel 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords