Cold Rolled Steel Coil with High Quality and Wide Reputation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

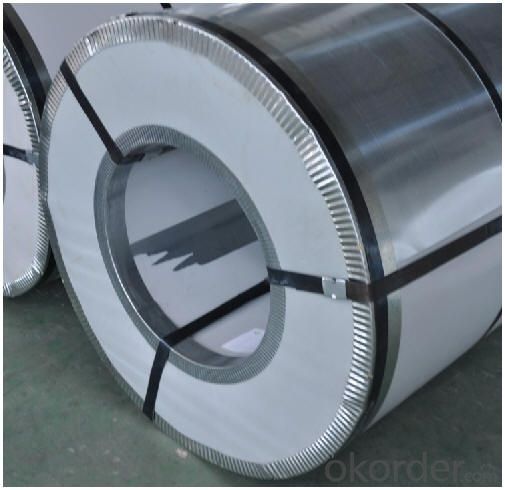

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: my sister is making rolls and we have no idea what steel cut oats are. can someone please help with this?

- It does NOT look or cook like oatmeal but is made from the same grain. It takes much longer to cook since it is a whole grain, and tastes very good by the way. If you hate the slimy feel of oatmeal, this is the one to try, with all the same nutritional goodness of oatmeal. You can find it in most grocery stores in the hot cereal aisle. EDIT: you are right Mnt. Camp, steel cut is better that the regular oatmeal.

- Q: How are steel coils used in the manufacturing of automotive chassis?

- Steel coils are used in the manufacturing of automotive chassis as they provide the necessary strength and durability required to support the weight of the vehicle and withstand various stresses and impacts. These coils are processed and formed into various structural components, such as frame rails and cross members, which form the foundation of the chassis.

- Q: What are the common methods of cutting steel coils?

- The common methods of cutting steel coils include shearing, slitting, and laser cutting. Shearing involves using a machine with two blades to cut through the coil. Slitting involves passing the coil through a set of rotating circular blades to create narrower strips. Laser cutting uses a high-powered laser beam to cut through the steel coil with precision.

- Q: I need to know how you rate the hardness of steel any ideas?

- Find your portable hardness testers from our latest collections thats for sure having the ability to test hardness of metal alloys and plastic by applying some amount of pressure on it. All our evaluators can evaluate in Brinell, Rockwell and Vickers machines.

- Q: How do steel coils compare to aluminum coils?

- Steel coils and aluminum coils possess distinct characteristics that render them suitable for varying purposes. Firstly, steel coils are renowned for their robustness and durability. They can endure high temperatures and exhibit greater resistance to damage in comparison to aluminum coils. Consequently, steel coils are an ideal choice for heavy-duty industrial applications necessitating sturdy materials, such as construction, automotive manufacturing, and the oil and gas industries. Additionally, steel coils boast heightened corrosion resistance, enabling their usage in outdoor environments characterized by harsh conditions. On the contrary, aluminum coils are lighter in weight and possess a higher strength-to-weight ratio than steel coils. This renders them exceptionally well-suited for industries wherein weight serves as a critical factor, such as aerospace and transportation. Furthermore, the malleability of aluminum coils facilitates easier shaping and forming, thereby proving advantageous in industries like packaging and consumer electronics. Moreover, aluminum coils exhibit superior thermal conductivity when compared to steel coils, rendering them more efficient in heat transfer applications. This particular attribute proves beneficial in industries such as HVAC (heating, ventilation, and air conditioning) and refrigeration, where the achievement of efficient heat exchange is of utmost importance. Concerning cost, steel coils generally prove more affordable due to the lower cost of raw materials. However, aluminum coils can yield long-term cost savings as they require less maintenance and possess a longer lifespan owing to their resistance to corrosion. In conclusion, the selection between steel coils and aluminum coils hinges on the specific requirements of the application at hand. Steel coils are favored for their strength, durability, and corrosion resistance, while aluminum coils excel in lightweight applications, heat transfer, and malleability.

- Q: What are the different types of steel coil handling attachments?

- Some of the different types of steel coil handling attachments include coil lifters, coil grabs, coil hooks, coil tongs, and coil C-hooks. These attachments are designed to safely lift, transport, and manipulate steel coils of various sizes and weights.

- Q: Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- Hey Bunny:) Glad you asked! I know of no one ,at all,that thinks steel toes are better than good reflexes and the ability to move faster! Wellies give flex,Sport shoes give speed, Jods(Paddocks) are the work boot of choice..and if there is one thing we know about horses, nothing happens in slo-mo! There is a fiberglass toe protector a person could use.. I guess..not this person though. Added to the factor that they have that bumpy sole not suited for riding, and a bad heel, and are just plain too heavy. And ankles! nothing special there. My flatmate(roomie) is an Equine reproduction Vet and a Polo Player, and no-one there has anything but jods and wellies. No clunky boots please:) Come to think of it, its been years since Ive mashed a foolish toe..and that takes into account trailering vetting and young-stock work....Yes I vote for movement over safety ** there are no horse-goods for sale with toe caps ** Three cheers for mobility bunny! (and wellies disinfect real nice too)

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand varies depending on the specific grade and type of steel being used. Steel is known for its high heat resistance and can typically withstand temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. However, it is important to note that prolonged exposure to high temperatures can cause steel to lose its structural integrity and result in permanent deformation or even failure. Therefore, it is crucial to adhere to the manufacturer's guidelines and specifications when determining the maximum temperature that steel coils can withstand in specific applications.

- Q: How do steel coils contribute to the HVACR industry?

- The HVACR industry relies heavily on steel coils, which play a vital role in various applications. These coils, typically made from durable and corrosion-resistant materials like stainless steel or galvanized steel, ensure longevity in demanding HVACR environments. Air conditioning systems commonly use steel coils to transfer heat between the refrigerant and the surrounding air. These coils, also known as evaporator coils, absorb heat from indoor air, cooling it down and removing moisture. The heat is then released outside through a condenser coil, enabling efficient cooling and dehumidification. Heat exchangers, crucial components in HVACR systems, also utilize steel coils. These coils, often in the form of finned tubes, provide a large surface area for efficient heat transfer, enhancing overall system efficiency. In the construction of ductwork, steel coils are extensively employed. These coils are shaped and sized to fit specific ductwork designs, ensuring optimal airflow and temperature control. Their durability and strength allow them to withstand the pressure and forces exerted by airflows in duct systems. Refrigeration systems rely on steel coils to transfer heat out of enclosed spaces, such as refrigerators or freezers. These coils, called condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. Steel coils are essential in the food service and cold storage industries, where they enable the cooling and preservation of perishable goods. Overall, steel coils significantly contribute to the HVACR industry by facilitating efficient heat transfer, optimal temperature control, and reliable operation of various systems. Their durability, corrosion resistance, and versatility make them crucial components in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- I would stick with what was on the bike steal front/rear and same chain size. I'm not crazy about changing the gearing, but it's definately important to stick to the stock stuff. steal lasts longer and a stock size chain is likely to last longer. I got 25.5k miles out of my stock chain/sprockets on my RC51. I went with stock gearing vortex steel front and JT steel rear and the top 530 EK chain. I expect that I will get another 25k miles before the set is changed again. I'm so used to the tall first gear, and don't need quicker accelleration. I also don't want to mess up the displayed road speed and recorded miles.

Send your message to us

Cold Rolled Steel Coil with High Quality and Wide Reputation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords