Cold Rolled Steel Coil SPCC DC01 SPHC DC02

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, GB, JIS | Thickness: | 0.3-1.8mm | Place of Origin: | Hebei, China (Mainland) |

| Brand Name: | CNBM | Model Number: | cold rolled steel coils | Type: | Steel Plate |

| Technique: | Cold Rolled | Surface Treatment: | Coated, Bright finish, Plating | Application: | building and constructions |

| Special Use: | High-strength Steel Plate | Width: | 1250, 600-1250mm | Length: | as required |

| Coil ID: | 508/610mm | Grade: | Q195~Q345,SPCC/SPCD/DC01 | Coil weight: | 3-12 MT |

| Zinc Coating: | 30-275g/ m2 |

Packaging & Delivery

| Packaging Details: | Standard export seaworthy package |

| Delivery Detail: | Within 20 days after received the prepaid |

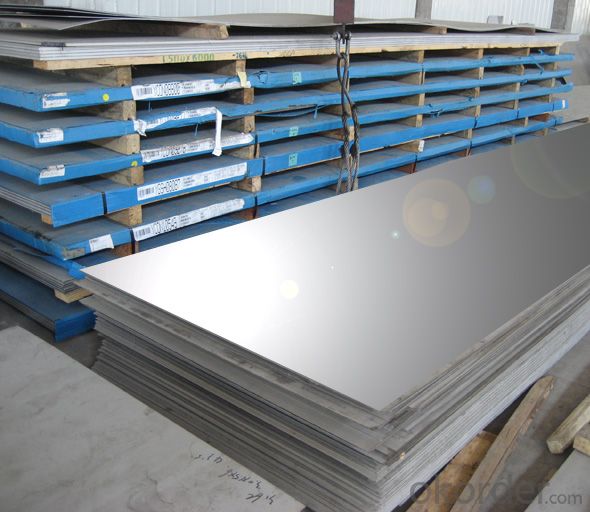

SPCC SPCD SPCE Cold rolled steel coil/sheet

Product details

| 1,product name | SPCD Cold rolled steel coil/sheet |

| 2,Standard | AISI,ASTM,BS,DIN,GB,JIS |

| 3,Executive standards | Q/HB04-2008(Cold Rolled Sheets and Strips) |

| 4,Inspection | ISO/BV/SGS |

| 5,certification | ISO9001 |

6,material | Q235B, Q345B, SPHC, SPHD,SPHE,510L , Q345A,Q345E |

7,steel grade | SPCC, SPCD, ST12, ST13, ST14/16, DC01, DC02, DC03, DC04, DC05, DC06, |

8,thickness | 0.16-3.5mm |

9,width | 900-1450mm |

10,surface treatment | coated&galvanized&bright/black annealed/unoil |

11,packing | Standard export packing or according to the clients required |

12,coil weight | 5-10tons |

13,Coil inner diameter | 508/610mm |

14,coil outer diameter | Max.Φ1500 or as your request |

15,usage/main application | transportation machine,Container Plate,chemical,building industry,automobile |

| 16,Product Category | galvanized,coated,spcc,spcd,spce,etc |

| 17, Spangle State | regular spangle, small spangle, big spangle, non-spangle |

| 18,Product Feature | High Surface Finish; Uniform coating thickness; High tensile strength(>600); Excellent atmospheric corrosion resistance,welding and cold forming performance; Leaf-shaped crystalline pattern; Beautiful Designed |

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- Carbon steel chef's knives out perform stainless in every aspect except 1, care. You can't put them in a dishwasher. Wash, rinse and dry off. Do not keep them in a drawer filled with other kitchen stuff, rather, keep them in a cabinet or block. If it starts to rust you can use steel wool to clean them up, or fine grit sandpaper if you want to retain a fine finish. For your viewing pleasure, a chef's knife I forged from crane cable.

- Q: What are the quality control measures for steel coil production?

- Quality control measures for steel coil production are essential to ensure that the final product meets the required standards and specifications. Here are some key quality control measures commonly employed in the steel coil production process: 1. Raw Material Inspection: Before production starts, the raw materials such as steel billets are thoroughly inspected for their chemical composition, mechanical properties, and surface defects. This ensures that only high-quality materials are used in the production process. 2. Process Control: Throughout the production process, various process control measures are implemented to monitor and control critical parameters. These may include temperature control, rolling speed, tension control, and lubrication. Regular checks and adjustments are made to ensure that these parameters are within the specified tolerances. 3. Dimensional and Surface Inspection: Steel coils undergo rigorous dimensional and surface inspections to ensure that they meet the required thickness, width, and length specifications. Surface defects such as scratches, pits, or dents are also carefully examined and minimized to meet quality standards. 4. Mechanical Testing: Mechanical properties such as tensile strength, yield strength, elongation, and hardness are tested on a regular basis. These tests are crucial to ensure that the steel coils possess the desired strength and performance characteristics. 5. Visual Inspection: Visual inspection is an important quality control measure to identify any visible defects or irregularities in the steel coils. Trained inspectors check for issues like cracks, corrosion, or uneven surfaces, and take necessary actions to rectify or reject the faulty coils. 6. Non-Destructive Testing: Non-destructive testing methods like ultrasonic testing, magnetic particle testing, or eddy current testing are often employed to detect internal defects such as voids, inclusions, or discontinuities that may impact the quality of the steel coils. 7. Documentation and Traceability: Proper documentation and traceability of all quality control measures are maintained throughout the production process. This includes recording test results, inspection reports, and other relevant data to ensure transparency and accountability. 8. Continuous Improvement: Quality control measures in steel coil production are not static but subject to continuous improvement. Regular audits, feedback from customers, and analysis of process data are used to identify areas for improvement and implement corrective actions to enhance product quality. By implementing these quality control measures, steel coil manufacturers can ensure that the final product meets the required specifications, performs reliably, and achieves customer satisfaction.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and repurposed for various applications in different industries.

- Q: What are the different types of steel finishes available for coils?

- There are several types of steel finishes available for coils, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include stretch film, shrink wrap, steel strapping, and wooden or cardboard cradles.

- Q: What is the accuracy of steel tape inspection?

- In addition, the project is through the detection of steel tape, steel tape each batch have the error him different, so do projects each into a batch of steel tape has to go through the inspection department, let this batch of steel tape has reached the same error range. All the measuring tools in this project are unified into these steel tape measures, so that the measurement error is guaranteed

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: What is the average thickness tolerance for steel coils?

- The average thickness tolerance for steel coils can vary depending on the specific industry and application. However, a common tolerance range for steel coils is typically around +/- 0.005 to 0.01 inches.

- Q: I already have the county permits and bank loan, but the foundation hasn't been poured. Is it too late to convert to steel?

- Steel is going to be a whole different world. You will need to go back to square one and get house plans that are drawn for structural steel. First thing you need to do is find a builder that knows how to build with steel and get an idea of the price.

- Q: What are the different types of steel coil packaging methods?

- There are several types of steel coil packaging methods, including strapping, wrapping, and stacking. Strapping involves using metal or plastic bands to secure the coil and prevent it from unwinding. Wrapping is done by covering the coil with a protective layer, such as plastic or paper, to shield it from moisture and damage. Stacking involves placing multiple coils on top of each other, usually on pallets, to optimize storage space and facilitate transportation.

Send your message to us

Cold Rolled Steel Coil SPCC DC01 SPHC DC02

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords