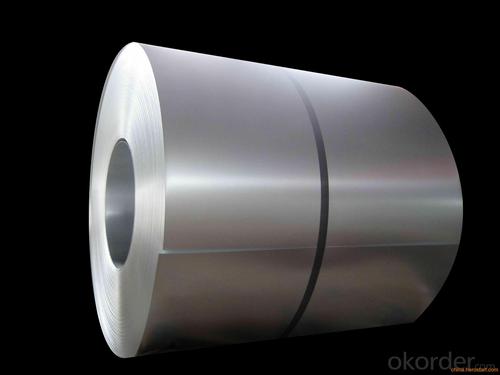

Cold Rolled Coil Strips/Galvanized Steel Coil Z275/Hot Dipped Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

cold rolled strips

1. width: 19-1500mm

2. thickness :0.2-3.0m,2.0-13.5mm

3.zinc coating:z60-z275

4.GB,JIS,ASTM,DIN,EN

cold rolled strips

Product Description

Brand : ZHCX | Standard: ASTM; ASTM; EN;GB | Grade:DX51D /DX52D/DX53D/ S250,280,320GD,Q195,Q235,etc. |

Thickness: 0.2-3.0mm 2.0-13.2mm | Width:19-1500mm | Length:Coil or upon request |

Zinc Coating: 40g- 275g/m2 | Surface: zero spangle, min spangle , regular spangle ,big spangle | Application: PPGI coil;construction,hardware, home appliances,interior decoration etc. |

Coil ID: 508-610mm | Coil Weight: 3-5 tons | Type : coil or sheet |

Packing: | 1.wooden case or wooden pallet 2.standard seaworthy packing | |

Delivery Time | Within 7-25 days after received the deposit | |

Brief Introduction

1. Prepainted Galvanized Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metal for Prepainted Galvanized Steel Coil is HDGI Steel. The finish coats of Prepainted Galvanized Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Galvanized Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Galvanized Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Edit

Because there is no after annealing treatment, the hardness is very high (HRB greater than 90), mechanical processing performance is poor, only a simplebending process has less than 90 degree directional (direction perpendicular to the rolled).

3, use three

Edit

Hot rolled products with high strength and good toughness, easy processing and good forming can be excellent performance of welding, which is widely used in ships, cars, bridges, buildings, machinery, boiler, pressure vesselmanufacturing industry.

The scope of application:

(1) after annealing processing into the common cold;

(2) processing galvanized galvanized unit before the annealing treatment;

(3) the basic do not need to process the panel.

4 four, classification

Edit

Carbon steel plate, carbon plate, low alloy plate, ship plate, bridge plate, boiler plate, container plate etc.. Rolling hard volumes: under normal temperature,the hot pickling volumes of continuous rolling.

Hot rolled steel strip products include steel (roll) and the shear of steel plate.And steel (coils) can be divided into straight and finishes volume (the volume,smooth rolling and slitting roll).

- Q: What is the difference between a matte and glossy steel sheet?

- The main difference between a matte and glossy steel sheet lies in their surface finish. A matte steel sheet has a dull, non-reflective surface that diffuses light, resulting in a more muted appearance. On the other hand, a glossy steel sheet has a smooth, reflective surface that reflects light, giving it a shiny and polished look.

- Q: Can steel sheets be used for solar panel mounting systems?

- Yes, steel sheets can be used for solar panel mounting systems. Steel is a durable and strong material, making it suitable for providing structural support and stability to the solar panels. Additionally, steel sheets can be easily customized and shaped to fit the specific requirements of the solar panel installation.

- Q: What are the different storage methods for steel sheets?

- There are several different storage methods for steel sheets, depending on the specific requirements and space availability. Here are some commonly used storage methods: 1. Flat storage: This is the most basic method where steel sheets are stored horizontally on a flat surface, such as the floor or metal racks. It is suitable for small quantities or when the sheets are not too heavy. 2. Vertical storage: Steel sheets can be stored vertically by placing them against a wall or by using specially designed vertical racks. This method saves floor space and allows for easy access and identification of different sheet sizes. 3. Cantilever racks: These racks have horizontal arms that extend outward from a vertical column, providing support for steel sheets placed on them. Cantilever racks are ideal for storing long and heavy steel sheets, as they allow for easy loading and unloading using forklifts or cranes. 4. Roll-out racks: These racks have rollers or ball bearings that allow steel sheets to be easily rolled in and out, similar to a drawer. Roll-out racks are useful when frequent access to different sheets is required, as they provide good visibility and easy retrieval. 5. A-frame racks: A-frame racks have angled arms that support steel sheets in a slanted position, resembling the letter "A." This method is suitable for storing large quantities of steel sheets and provides easy access while keeping them organized. 6. Automated storage and retrieval systems (AS/RS): These systems use computer-controlled mechanisms to automatically store and retrieve steel sheets. AS/RS can be designed as vertical lift modules or robotic systems, maximizing storage capacity and efficiency. It is important to consider factors such as sheet size, weight, accessibility, and safety when choosing the appropriate storage method for steel sheets. Adequate measures should also be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially affect their quality.

- Q: What is the difference between a galvanized and painted steel sheet?

- A galvanized steel sheet is one that has been coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, involves immersing the steel sheet in a bath of molten zinc, which forms a bond with the underlying steel. This zinc coating acts as a sacrificial anode, meaning that it corrodes instead of the steel when exposed to elements such as moisture and oxygen. As a result, galvanized steel sheets have excellent corrosion resistance and can last for a long time in outdoor environments. On the other hand, a painted steel sheet is one that has been coated with a layer of paint to provide both aesthetic appeal and additional protection against corrosion. The paint acts as a barrier between the steel surface and the surrounding environment, preventing moisture and other corrosive substances from coming into direct contact with the steel. This helps to prolong the lifespan of the steel sheet and maintain its appearance. In terms of appearance, galvanized steel sheets have a characteristic silver-gray color due to the zinc coating, while painted steel sheets can come in a wide range of colors depending on the type of paint used. Galvanized steel sheets also have a textured surface due to the presence of the zinc coating, while painted steel sheets can have a smoother or textured finish depending on the application technique. Ultimately, the main difference between galvanized and painted steel sheets lies in the method of protection against corrosion. Galvanized steel relies on the sacrificial corrosion of zinc, while painted steel relies on the barrier effect of the paint. The choice between the two depends on factors such as the specific application, aesthetic requirements, and the level of corrosion resistance needed.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- For decorative purposes, one can find several varieties of steel sheet finishes that are commonly utilized. These finishes are applied to the steel sheet's surface with the intention of enhancing its appearance and achieving a desired aesthetic effect. Some of the most favored finishes for decorative purposes are as follows: 1. Brushed Finish: Achieved by brushing the steel sheet's surface with a fine abrasive material, usually in a straight line pattern, this finish imparts a smooth and satin-like appearance. It is widely used in architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this type creates a highly reflective surface that resembles a mirror. The steel sheet is mechanically polished to achieve this finish, and it is commonly seen in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the steel sheet's surface. It can be achieved through various techniques like stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: To add vibrancy and enhance visual appeal, steel sheets can be coated with a colored finish. Processes such as powder coating are employed, where a dry powder is applied to the steel sheet and then cured to create a durable, colored finish. Colored finishes are commonly used in architectural applications like building facades and signage. 5. Antique Finish: This particular finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. Various techniques such as chemical treatments, patinas, or distressing can be employed to achieve this appearance. Antique finishes are often utilized in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the diverse range of steel sheet finishes available for decorative purposes. Each finish provides a distinct appearance and can be customized to suit specific design preferences. The choice of finish relies on factors such as the desired look, application, and required level of durability for the project.

- Q: How do steel sheets perform in corrosive environments like saltwater?

- Steel sheets exhibit excellent resistance to rust and corrosion in corrosive environments like saltwater. This is primarily due to the presence of chromium in the steel, which forms a protective layer of chromium oxide on the metal surface. This layer acts as a barrier, preventing direct contact between the steel and the corrosive elements in saltwater, thereby reducing the risk of corrosion. However, it is important to acknowledge that steel sheets are not completely immune to saltwater corrosion. Extended exposure to saltwater can still lead to some degree of corrosion, particularly when combined with other factors such as high temperatures, abrasion, or impurities in the water. To enhance the performance of steel sheets in saltwater environments, various protective coatings can be utilized. These coatings, including paint, galvanization, or epoxy, provide an extra layer of protection to the steel, further minimizing the chances of corrosion. Regular maintenance and inspection are vital to ensure the long-term effectiveness of steel sheets in saltwater environments. This involves cleaning the surface, eliminating any accumulated salt or debris, and rectifying any damaged or compromised areas of the protective coating. Overall, although steel sheets possess good resistance to corrosion in saltwater environments, it is imperative to take appropriate precautions such as using protective coatings and conducting regular maintenance to ensure their optimal performance and durability.

- Q: Is galvanized iron sheet the same as galvanized steel sheet? solve

- The same thing is done to slow down the rate of oxidation. Because the zinc is more active than the iron, the zinc first responds, the zinc reaction is finished, iron should. Thereby slowing down its oxidation.

- Q: Are steel sheets suitable for elevator shafts?

- Yes, steel sheets are suitable for elevator shafts. Steel is a durable and strong material that can withstand the structural requirements and load-bearing capacity needed for elevator shafts. Additionally, steel sheets can be customized and fabricated to fit the specific dimensions and design of the elevator shaft.

- Q: What are the different standards and certifications for steel sheets?

- Steel sheets must adhere to numerous standards and certifications in order to ensure their quality and compliance with industry requirements. Some of the well-known ones are: 1. ASTM International: To establish the mechanical and chemical properties of steel sheets, ASTM A1008/A1008M provides a standard specification for cold-rolled, carbon, structural, high-strength low-alloy steel sheets with improved formability. 2. American Iron and Steel Institute (AISI): Various standards are offered by AISI for different types of steel sheets, such as AISI 4130, AISI 4140, AISI 4340, etc. These standards outline the chemical composition, mechanical properties, and heat treatment requirements for specific steel sheet types. 3. International Organization for Standardization (ISO): ISO has developed standards like ISO 3574, ISO 630, and ISO 4998 to cover dimensional tolerances, mechanical properties, and technical delivery conditions for specific steel sheet grades. 4. European Committee for Standardization (CEN): CEN has defined requirements for cold-rolled, hot-rolled, and high-strength steel sheets through standards like EN 10130, EN 10025, and EN 10149 respectively. These standards encompass aspects such as chemical composition, mechanical properties, and surface finish. 5. Japan Industrial Standards (JIS): JIS standards like JIS G 3141, JIS G 3131, and JIS G 3132 are widely used for cold-rolled, hot-rolled, and hot-rolled high-strength steel sheets respectively. They specify the mechanical properties, chemical composition, and dimensional tolerances of steel sheets. Furthermore, steel sheet manufacturers can obtain various certifications to demonstrate their adherence to specific quality and environmental management systems. Some widely recognized certifications in the steel industry include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and OHSAS 18001 (Occupational Health and Safety Management System). These certifications guarantee that manufacturing processes and products meet the required standards while being produced in an environmentally sustainable and safe manner.

- Q: What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- Hot dipped galvanized and electro galvanized steel sheets are both types of galvanized steel, but they differ in the method of application and the resulting characteristics of the coating. Hot dipped galvanized steel sheets are made by immersing the steel into a molten zinc bath. This process creates a thick, durable coating that provides excellent corrosion protection. The steel is completely coated in zinc, both on the surface and on the edges, ensuring complete coverage and protection against rust and other forms of degradation. The coating thickness can vary depending on the application and the required level of protection. On the other hand, electro galvanized steel sheets are produced by electroplating steel with a thin layer of zinc. The steel is first cleaned and treated with an acid solution to remove impurities and improve adhesion. Then, it is immersed in a zinc electrolyte solution, and an electric current is passed through the bath, causing the zinc ions to bond with the steel surface. This process results in a much thinner coating compared to hot dipped galvanized steel. Due to the thinner coating, electro galvanized steel sheets provide less corrosion protection than hot dipped galvanized steel sheets. They are more suitable for indoor applications or environments with less exposure to harsh conditions. However, electro galvanized steel sheets offer other advantages such as a smoother and more uniform appearance, making them popular for applications where aesthetics are important, such as automotive parts or appliances. In summary, the main difference between hot dipped galvanized and electro galvanized steel sheets lies in the method of application and the resulting coating thickness. Hot dipped galvanized steel sheets have a thicker, more durable coating, providing superior corrosion protection, while electro galvanized steel sheets have a thinner coating, making them more suitable for indoor applications and offering a smoother appearance.

Send your message to us

Cold Rolled Coil Strips/Galvanized Steel Coil Z275/Hot Dipped Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords