Cold Rolle Steel Coil DC01 DC01EK DC04EK

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Cold Rolle Steel Coil

The raw material of cold rolled steel coil is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc.

Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed.

Standard: AISI,ASTM,BS,DIN,GB,JIS

Grade: DC01

Thickness:0 .8/1.0/1.2/1.5

Technique: Cold Rolled

Surface Treatment: Bright or black annealed

Width: 900mm-1500mm

Steel Grade: DC01, DC01EK, DC04EK

Tensile Strength: 270Mpa

Yield Strength: 270-410Mpa

AVAILABLE SPECIFICATION

| Thickness | 0.3-4.0mm (Full Hard Starting From 0.10mm) |

|---|---|

| Width | 30-2000mm |

| Sheets Length | 0-6000mm |

| Coil ID | 508mm or 610mm |

| Surface Treatment | Matt Finish/Bright Finish, Oil/Dry |

| Annealing Methods | Bright Anneal/ Black Anneal |

| Coil Weight | 5MT-25MT |

| APPLICATION | Steel Drum,Galvanized Steel, Steel Pipe, Home Appliance,Automobile etc. |

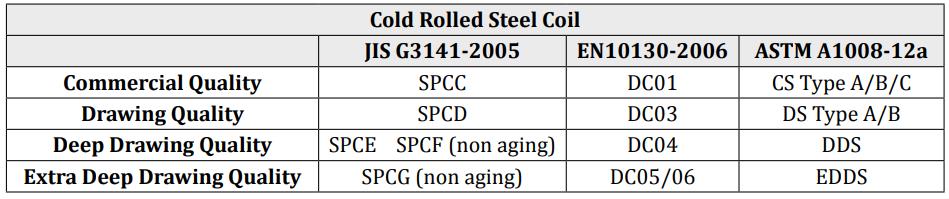

STANDARD & GRADE

Package & Shipment

| Package | Export standard packing(can do as required) |

| Container shipment | 20ft container/40ft container |

| Bulk shipment | if big order,then will save freight cost(while shipline may only one time one month) |

| Delivery | 20days(short as 7days,as many sizes in stock ) |

Picture of Cold Rolle Steel Coil

APPLICATION

Steel Drum, Galvanized Steel, Steel Pipe, Home Appliance, Automobile etc.

- Q: I'm not really sure if carbon steel is considered a metallic material.

- Carbon and iron are both metallic.... so yes. You leave the iron laying in the forge - and it soaks up carbon atoms from the charcoal - so that as the steeling process goes on, the original iron becomes harder and harder.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- of course you couldn't find it, the weigh depends on the size of the piece. What you are looking for, I think, is density. Below are a few tables, there are lots more. .

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency through visual inspection by trained personnel. They compare the color of the coils against a color standard to ensure uniformity and consistency across the entire batch.

- Q: How are steel coils inspected for defects after recoiling?

- Steel coils are inspected for defects after recoiling by conducting visual inspections, using non-destructive testing methods such as ultrasonic testing or magnetic particle inspection, and conducting measurements to check for dimensional accuracy and straightness.

- Q: What is the role of steel coils in the production of fencing materials?

- Steel coils play a crucial role in the production of fencing materials as they are used to create the wire mesh that forms the main structure of the fence. The coils are unraveled and fed into a machine which cuts and shapes the steel into the desired size and form. This wire mesh is then further processed and treated to enhance its strength and durability before being incorporated into the final fencing products.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are commonly used in the manufacturing of drivetrains as they provide the necessary strength and durability required for these critical components. The steel coils are typically formed into various shapes, such as gears, shafts, and axles, which are then machined and assembled to create the drivetrain system. These steel components help transfer power from the engine to the wheels, allowing the vehicle to move efficiently and smoothly.

- Q: I am refinishing a table and on my can of polyurethane, it indicates not to sand with steel wool prior to application. Why is that?

- Steel wool will leave invisible pieces of metal embedded in the finish, no matter how much you try to wipe it off. When you cover it with the polyurethane, it is trapped and turns dark over time, ruining the look of the table. Yeh, so follow the directions exactly for the best finish. Good luck!! : /

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve inspecting the damage, assessing its severity, and determining if the coil is still safe to handle. If the damage is minor, it may be possible to repair or reinforce the coil. However, if the damage is extensive or compromises the structural integrity of the coil, it is recommended to contact a professional for further evaluation and potential disposal. Additionally, following proper safety protocols, such as wearing protective gear and using equipment suitable for handling heavy loads, is crucial when dealing with damaged steel coils.

Send your message to us

Cold Rolle Steel Coil DC01 DC01EK DC04EK

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords