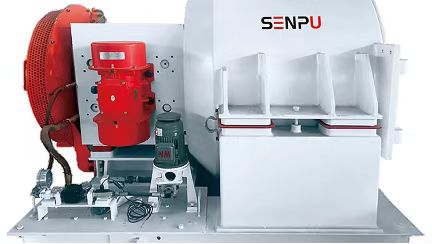

Coal washing and beneficiation equipment HVC Horizontal Vibrating Discharge Centrifuge

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The LWZ screen-bowl centrifuge is suitable for the dewatering and recovery of -0.5mm coal fines. It offers a series of advantages, including large capacity, low product moisture, simple drive system, long service life of wearing parts and use of intelligent control system. It has been awarded 4 national patents and the honors of being a research-derived achievement of Hebei Province and National Key New Product, and is the winners of 5 prizes bestowed by China Building Material Group and Tangshan City for its scientific and technological progress, etc. Now, 6 sizes ranging from LWZ800×1600 to LWZ1600×2400 are available.

This kind of centrifuge is suitable for the dewatering and recovery of fine cleaned coal or small middlings. It offers a series of advantages, including high capacity, low product moisture, low noise level, stable vibrating amplitude, low fault rate and easy replacement of worn-out parts. It can be used as a substitute for an imported counterpart. The centrifuge has been granted 2 national patents. Now, 7 sizes ranging from HVC1000 to HVC1650 are available.

- Q: What is the sieving box of the vibrating screen?.

- The screen box is a coat screened by a linear vibrating screen. It is made of steel plate by welding

- Q: What are the advantages of ultrasonic vibrating screen?

- 1. ultrasonic vibration sieve technology for different materials, such as particle size, density and particle shape, screening, research and development and production;2., it has solved the sieving problems of strong adsorption, easy to hold together, strong stickiness, high static electricity, high density, superfine powder and other characteristics;

- Q: Is the working principle of the swing screen the same as that of other vibrating screens?

- The working principle of a wobble screen is similar to that of other vibrating screens, but some of them are different

- Q: What is the difference between a high frequency linear vibrating screen and an ordinary linear vibrating screen?

- It is precisely because the high frequency high frequency linear vibrating screen motor speed is high, the screening machine vibration frequency is also high, the unit time processing material is more, therefore the output aspect is higher than the ordinary high frequency linear vibration sieve.

- Q: What are the technical requirements of the vibration screen installation?

- The inclination angle of the screen shall meet the requirements of the drawing, and the deviation shall not be greater than + 0.5.. The installation angle of the sieve body suspension boom shall comply with the requirements of the drawing, and the deviation shall not be greater than + 0.5.

- Q: General ultrasonic vibration sieve for the purpose of how many nets, 100 of the target material does not add ultrasonic influence?

- The 100 purpose material you mentioned may use a three dimensional vibratory screen, but if your material has the characteristics described above, it is recommended to use an ultrasonic vibrating screen.

- Q: How many methods do you use to fix the screen surface of vibrating screen?

- Wedge clamping wedge pressing: refers to the use of wedge to sieve surface is fixed on the frame of the mode of vibration sieve. The pressing method is suitable for the punching sieve plate and the slit screen surface.

- Q: How does a vibrating screen work in a rock yard? What is its principle?

- vibration motor foot bolt should be based on the corresponding diameter of not less than 8.8 of the high strength bolts with a spanner, reliable fastening and using anti loosing measures, there should not be any slack. Generally use flat pad and double nut fastening and prevent loosening. Tighten the assembly bolts in the order shown.

- Q: What kind of vibrating screen is used in the coal preparation plant?

- According to the raw materials, coal particle size composition, moisture and other factors, as well as the use (such as raw coal, large particle size classification, desliming, off the media, etc.) to determine.

- Q: Can the discharge hole of the linear vibrating screen be adjusted at will?

- Can be customized according to the needs of the design, and can be made into a round, put, can also increase the longer, may also need to design direction.

Send your message to us

Coal washing and beneficiation equipment HVC Horizontal Vibrating Discharge Centrifuge

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products