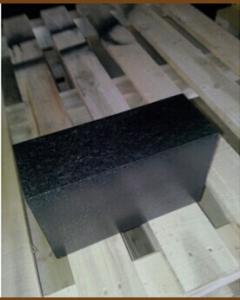

CNBM Magnesite Brick Refractory Materials Magnesia Brick

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX magnesite brick is made of various grades of magnesia and is a kind of alkali resistance refractory brick.

Features:

High Refractoriness

Excellent Alkali-resistant Function

High Refractoriness under Load

Applications:

Arc Furnace hearth and walls

Permanent Working Layer of Oxygen Converter

Smelting Furnace

Furnace walls and hearth of Reheating furnace

Chamber of glass furnaces

Item | MZ-97A | MZ-97B | MZ-95A | MZ95B | MZ-93 | MZ-91 | MZ-89 | DMZ98 | DMZ97 | DMZ96 |

Density(g/cm3)≥ | 2.96 | 2.96 | 2.94 | 2.94 | 2.94 | 850 | 900 | 3.1 | 3.1 | 3 |

Cold Crushing Strength (Mpa)≥ | 60 | 60 | 60 | 60 | 60 | 60 | 50 | 90 | 90 | 90 |

Reheating Linear Change (%) | 1650℃ x 2h | 1650℃ x 2h | 1650℃ x 2h | 1650℃ x 2h | — | — | — | |||

Refractoriness Under Load (℃)≥ | 1700 | 1700 | 1650 | 1650 | 1620 | 1560 | 1550 | 1700 | 1700 | 1700 |

Apparent Porosity(%)≤ | 16 | 18 | 16 | 18 | 18 | 18 | 20 | 14 | 14 | 15 |

MgO(%) | 97.0 | 96.5 | 95.0 | 94.5 | 93.0 | 91.0 | 89.0 | 97.7 | 97.1 | 96.3 |

SiO2(%) | 1.0 | 2.0 | 2.0 | 2.0 | 3.5 | — | — | 0.58 | 0.97 | 1.2 |

CaO(%) | — | — | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 0.63 | 0.97 | 1.3 |

Application | Kiln Linning in Iron and Steel, Copper, Lead, Tin and Zinc Industries | The Tap Hole of Steel Furnace; Tap Hole and Slag Line in Non-Ferrous Industry | ||||||||

Production Facilities

RAW Material Storage System, Machanical Arm for Package, Tunnel Kiln

Automatic Control System

Test & Certificate Centre– State Level

Chemical analysis

Bulk Density

Apparent Porosity

Packing

Automatic Packing Machine, Well-packed Brick

Water-proof, easy handling

Package of international standards

Flexible in types of packing

- Q: What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- In addition to the brine binder burned magnesia brick and sulfite pulp waste liquid, Magnesium Sulfate solution binder is generally around 3%

- Q: Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q: High purity magnesia brick masonry mortar for what?

- Always! There is no 800 degrees can be sintered chamotte? As long as the dregs and do not break the aluminum content, the magnesia brick stick together can!

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: Magnesia brick

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- According to the actual situation, design the brick you need, and the price of brick is determined by the index.

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

Send your message to us

CNBM Magnesite Brick Refractory Materials Magnesia Brick

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 100 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords