CMAX - WHEEL LOADER SERIE - 417 MODEL,High back-off brakes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

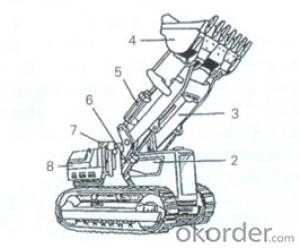

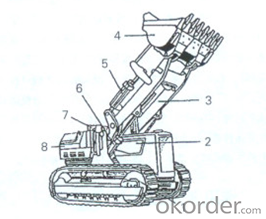

The JCB 417 is designed first and foremost to provide superb productivity and efficiency.

Built on a foundation of quality and reliability, this wheel loader provides high power and torque, as well as the ability to move more material for less money.

Its EcoMAX engine means this loading shovel meets Tier 4i/Stage 3B emissions legislation without exhaust after-treatment, while its spacious cab has enough comfort to meet the demands of any operator. It’s also an extremely safe machine that can maximise uptime with its easy servicing and low maintenance requirements.

The JCB 417 loading shovel’s tilting and telescopic steering column is easily adjusted. Operators can also choose their perfect control system: multi-lever, joystick and separate auxiliary lever, or our new joystick and electro-hydraulic proportional auxiliary control.

A stylish, modern central dash display on this loading shovel combines analogue dials and a colour LCD screen displaying machine health details, service requirements, operating information and more.

Air conditioning and automatic climate control options help to create perfect working temperatures in your wheel loader. The cab is insulated from the engine bay by a bulkhead and air chamber to keep noise and heat levels down.

Selectable loader arm detents mean operators can set height limitations, return to dig and float functions for improved safety and productivity. 3 or 4 spool hydraulics and a quickhitch enable many attachments to be used easily for extra versatility.

JCB Smoothride load suspension limits shock loadings on the 417 wheel loader, and therefore reduces material spillage and structural stress, as well as increasing operator comfort.

A 3-piece laminated front screen provides excellent visibility while interior mirrors, heated exterior mirrors, an optional reverse camera and a sloping rear bonnet give good rearward views.

Choose from a range of seat options: mechanical or air suspension, vinyl or fabric bases, or even our Actimo XXL option. It’s heated with air suspension, lumbar support, armrests, backrest extension and a headrest, all with full adjustment.

The Tier 4i EcoMAX engine in the JCB 417 loading shovel uses less fuel than our Tier 3 engines, saving you money. What’s more, it doesn't use exhaust after-treatment, meaning there’s no need for costly heat-resistant lube oils.

EcoMAX produces high levels of power and torque at low engine speeds for fuel efficient matching of transmission and hydraulics. The engine can also run on lower-grade fuels, allowing you to resell your machine in different territories for improved residuals.

High back-off brakes reduce viscous drag during roading and rehandling, which boosts fuel efficiency on your loading shovel.

The variable displacement pumps on the 417 feed a load-sensing valve block which only consumes power on demand, providing precise, efficient loader control.

The JCB 417 wheel loader’s viscous coupled engine fan automatically adjusts its speed depending on ambient temperature, optimising cooling, saving fuel and lowering noise.

Our regenerative dump circuit improves cycle times on this wheel loader; it also improves economy by reducing hydraulic power consumption. Not only that but the adjustable proportional auxiliary flow rate makes using specialist attachments easy.

The JCB 417 loading shovel can be specified for heavy-duty applications like waste or corrosive material handling. Auxiliary flow rate is also fully adjustable on the move for precision attachment control; you can even select constant flow for rotary attachments.

JCB's award-winning EcoMAX 4.4-litre engine delivers 93 kW (125 hp) and 550 Nm in this wheel loader; a variable geometry turbo offers increased performance at low engine speeds for improved cycle times and tractive effort.

With a choice of axle options you can tailor your JCB 417 to any application. Open differentials are ideal for hard standing ground conditions, while a limited slip differential is perfect for soft, muddy terrain with reduced traction.

Clever JCB electronic management can disconnect the clutch via the brake pedal for efficient, productive wheel loader operation. By controlling tractive effort through the transmission, this feature channels maximum power to the loader, reducing service brake wear and fuel consumption.

The JCB 417 loading shovel's variable displacement piston pump delivers a 156 l/min flow rate for ultimate multitasking.

So that you can perform parallel lifting and use plenty of attachments, there’s a high torque (HT) loader arm fitted to this wheel loader, with the option of a Super HT arm for high-up applications like hopper and lorry loading.

We've made sure that forward visibility on the JCB 417 is excellent, while our optional quickhitch makes attachment changing easy and efficient (even with aftermarket attachments).

To prove how good our EcoMax engines are, we've tested them for 110,000 hours in 70 different machines – including loading shovels – across the toughest applications and environments.

Finite element analysis and rig testing ensure superior structural strength and durability, while robot machining, precision paint technology and innovative assembly techniques achieve the very highest levels of quality. Cold cell testing guarantees starting performance down to -20ºC.

To protect the bonnet, recessed rear lights and cooling pack of this wheel loader from impact damage, we've fitted a full-width rear counterweight.

The hydraulic tank and fuel tank on a JCB 417 wheel loader are both integral to the chassis, providing protection as well as structural strength.

The articulation joint has a heavy-duty box section – much stronger than a single plate with a boss – and for protection, hoses are neatly routed and clamped through the articulation joint. Steering rams are high up and well guarded from damage.

Precision machining provides high tolerances and accurate location of pins and bushes; the articulation joint has a heavy-duty centre pin and oversized bush, as well as twin taper roller bearings, which can tolerate both vertical and horizontal loadings.

- Q: Dragon loader type 30 parameter

- 2. the frame structure of the finite element analysis has high strength and good reliability. 3. the working device linkage mechanism has been optimized by computer. The unloading height and the unloading distance have reached the ZL50 grade standard, and are among the best in the profession.

- Q: front load washers or top loaders?

- Dpend on if you want to bend then reach or just reach

- Q: is there anyway to set up the usb loader for the wii (softmod) so when you turn on the wii it will take you to the usb loader

- download homebrew channel and get usb loader thing and then load it from there :)

- Q: I'm just wondering what Free Loader is in Action Replay for Gamecube.

- Since your gamecube is region locked, games from japan or other countries will not work. However, with the free loader option, this lets you play these games on your gamecube.

- Q: I have a wii that I hacked and whenever I use configurable usb loader, a game freezes while loading after picking the one I want to play or during a game while loading to the next screen, freezes. I also hacked my cousin's wii, but everytime time I use the app on his wii, there is no problem whatsoever and his wii is WHITE. Mine is Black as you can tell by the question. I'm getting really irritated because I can't play the games and Idk what to do. Can someone please tell me how to fix this if possible? :[

- Configurable Usb Loader Download

- Q: i would like to know so i dont buy the q loader and waste my time and money on something that wont work. if you find any pictures i would appreciate it if you could show me.

- Yes, you can put a Q-loader on just about any paintball gun. The question is, is it worth it to use a Q-Loader? Will you only be shooting a couple hundred paintballs per game? Can you afford the high price of the Q-pods? Can you afford the higher quality paintballs you will have to use? Do you know that if you run out of paintballs, you can't borrow paint effectively in game.

- Q: What is loader and linker?

- In some computer programming languages, it is possible to write and compile the program in segments rather than all at once. When you do this, there are usually references that can't be resolved since they are in other segments (and at this point, each segment is completely independent of other segments). To combine the segments together into one program (and to complete the unresolved references), a LINKER is used. To actually run the program, it must first be loaded into memory. Usually, the compiler/linker makes a relocatable executable file. This simply means that the executable program can be loaded anywhere in memory (By comparison, a non-relocatable program must go into one specific place in memory). When the LOADER loads the program, it does the final steps to fix this iteration of the program into a specific place in memory (usually loading a specific memory address into a program register. The compiled program already has its memory references relative to this register, so it just needs a starting value). I hope this make sense. I'm writing it while I'm falling asleep at the computer

- Q: Where can I buy a sig sauer speed loader for a 226 15 rd clips?

- I do not know - you did not mention where you live. I sure hope you didn't mean to find a place to buy online. Since it only took me two seconds to find 200+ sellers and distributors........ you'd have been a total moron to have meant that.

- Q: i have a sony psp 2006 v4.01 but i cant play ISO or CSO formated games. is it hackable by ChickHEN loader with V5.03? or it is just upgradable with the latest v5.50? help please...

- u cant play ISO and CSO games because ur psp isnt hacked. which means you have OFW(Official Firmware) not CFW(CustomFirmware). you will need a pandora battery to hack ur psp for starters, i suggest u look on youtube for video tutorials how to do it. If you already have CFW then you must be trying to play new games on an old CFW, when u download your games always check what Firmware its been tested on b4 you dwload so u know if it will work on your psp or not. answer to your question YES the psp slim is hackable, i dont know about chikenloader i never used it, i always upgraded manually its pretty easy. goto youtube and type in SLIM 4.01 to 5.50GEN ChickHEN loader im sure something useful will come up.

- Q: I bought a used computer on Craigslist for around $200 for fixing up and reselling. It came with Windows 7 ultimate, which is weird seeing that a license for it costs close to $200 just by itself. I did the genuine check and it comes out as genuine but there's no COA.How can I be sure it's not running Windows Loader or some other quot;impossible to detectcrack?

- This may sound weird, but the Windows loader crack (called a SLIC loader) will be able to detect if your used computer has it. If you have a copy of it, it will tell you whether or not you have it, what kind of license your Windows install has, and other information.

Send your message to us

CMAX - WHEEL LOADER SERIE - 417 MODEL,High back-off brakes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords